WELDING FUME EXTRACTORS VS. RESPIRATORS: WHICH IS THE BETTER OPTION?

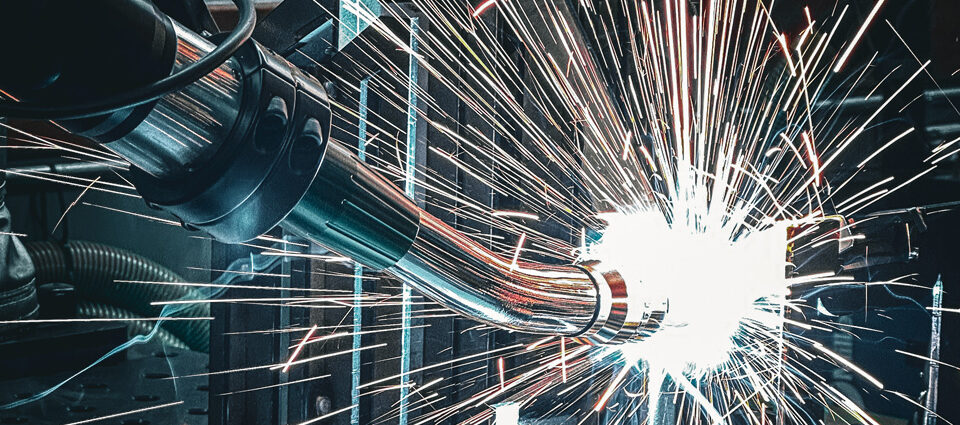

Welding is a commonly used process across various industries, including manufacturing, construction, and transportation. While welding is an essential process, it also produces harmful fumes that can lead to significant health problems, including lung damage, cancer, and even death. Therefore, it is critical to implement proper respiratory protection measures when welding.

The two primary respiratory protection options for welding are welding fume extractors and respirators. In this article, we will discuss the pros and cons of each option to help you decide which one is best for your workplace.

Welding Fume Extractors

Welding fume extractors are mechanical devices that are used to remove welding fumes from the air. These devices work by drawing the contaminated air through a filter or a series of filters, which trap the harmful fumes and release the clean air back into the work area.

Advantages of Welding Fume Extractors

Continuous Protection for All Workers in the Area

One of the significant advantages of welding fume extractors is that they provide continuous protection for all workers in the area. These devices work to remove fumes from the air, which means that all workers are protected, even if they are not wearing individual respiratory protection.

Removes Fumes at the Source

Another significant advantage of welding fume extractors is that they remove fumes at the source. These devices are positioned close to the welding area, which means that they can capture fumes as soon as they are produced. This is particularly important when welding in confined spaces or areas with poor ventilation.

No Need for Individual Fit Testing

Unlike respirators, welding fume extractors do not require individual fit testing. This means that they can be used by a variety of workers without the need for additional testing or adjustments.

Disadvantages of Welding Fume Extractors

Initial Cost May Be Higher Than Respirators

One of the primary disadvantages of welding fume extractors is that their initial cost may be higher than respirators. This is particularly true for larger, more complex models that are required for larger work areas or those with higher levels of fume production.May Require More Maintenance and Upkeep

Welding fume extractors require regular maintenance and upkeep to ensure that they are working correctly. This can include filter changes, cleaning, and other upkeep tasks that may be time-consuming and require additional resources.Respirators

Respirators are individual respiratory protection devices that are worn by workers to protect them from welding fumes. There are several types of respirators commonly used in welding, including disposable respirators, half-face respirators, and full-face respirators.

Advantages of Respirators

Lower Initial Cost Than Welding Fume Extractors

One of the primary advantages of respirators is that their initial cost is generally lower than welding fume extractors. This makes them a more cost-effective option for smaller work areas or those with lower levels of fume production.

Disadvantages of Respirators

Requires Individual Fit Testing for Each Worker

Unlike welding fume extractors, respirators require individual fit testing for each worker. This is to ensure that the respirator is providing adequate protection and that it fits the worker correctly. Fit testing can be time-consuming and may require additional resources.

May Not Provide Adequate Protection if Not Worn Correctly or if Filters are Not Changed Regularly

Respirators may not provide adequate protection if they are not worn correctly or if filters are not changed regularly. Workers may also be less likely to wear a respirator if it is uncomfortable or interferes with their work, which can put them at risk for exposure to harmful fumes.Welding Fume Extractors vs. Respirators: Which is the Better Option?

When it comes to choosing between welding fume extractors and respirators, there is no clear-cut answer. The best option for your workplace will depend on several factors, including the size of the work area, the level of fume production, and the type of welding being performed.

In general, welding fume extractors are the better option for larger work areas or those with higher levels of fume production. These devices provide continuous protection for all workers in the area and remove fumes at the source, which means that they are more effective at preventing exposure to harmful fumes.

Conclusion

In conclusion, welding fume extractors and respirators are both effective respiratory protection options for welding. However, the best option for your workplace will depend on several factors, including the size of the work area, the level of fume production, and the type of welding being performed. It is important to choose a respiratory protection option that provides adequate protection for all workers in the area and is in compliance with relevant safety regulations.

PRESS RELEASE: TRANSLAS-GARMO PARTNERSHIP

- translasadmin

- 11 June 2022

Revolutionizing Welding Fume Extraction: Translas Europe Shines at SCHWEISSEN & SCHNEIDEN

- translasadmin

- 2 October 2023