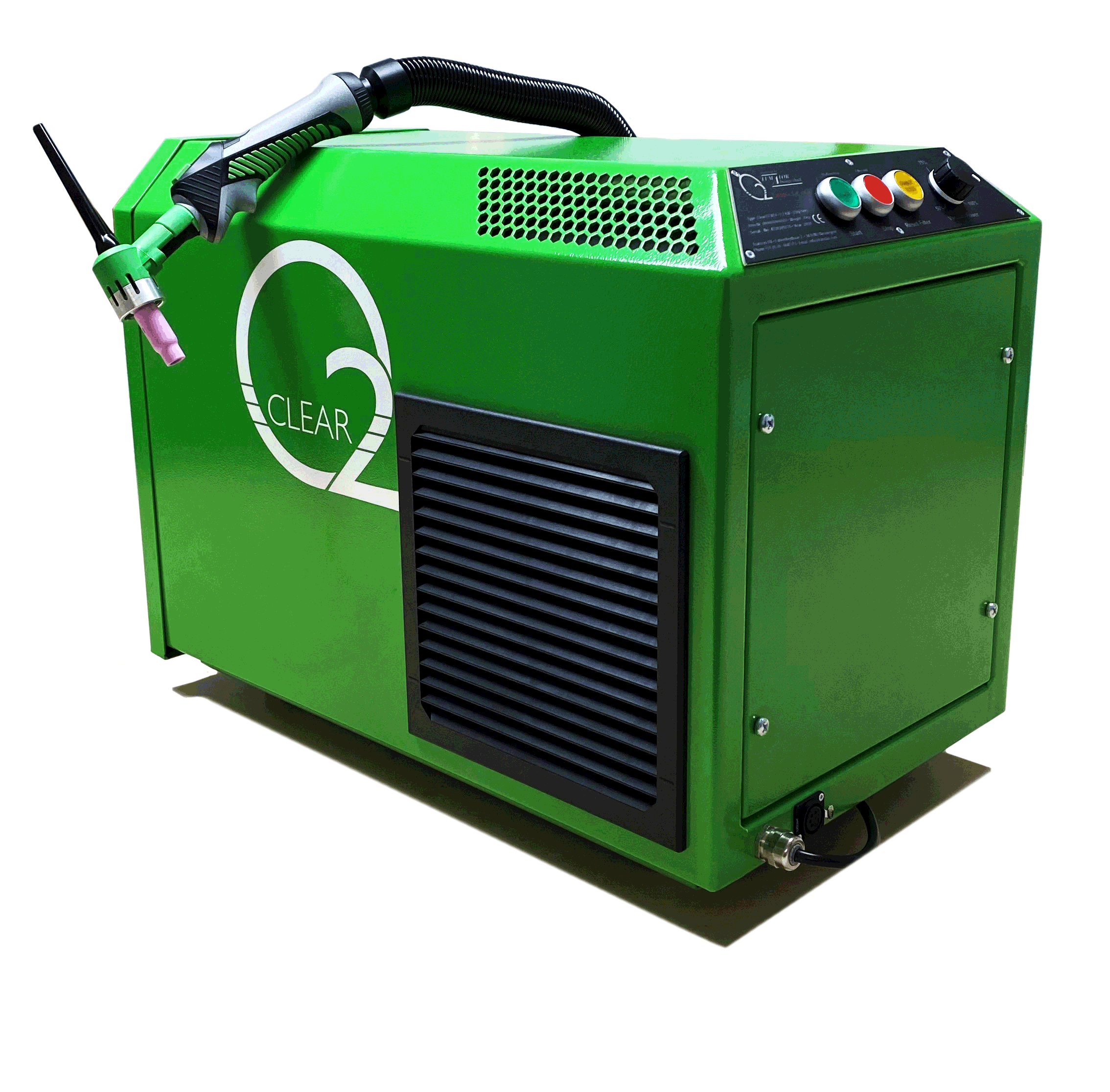

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

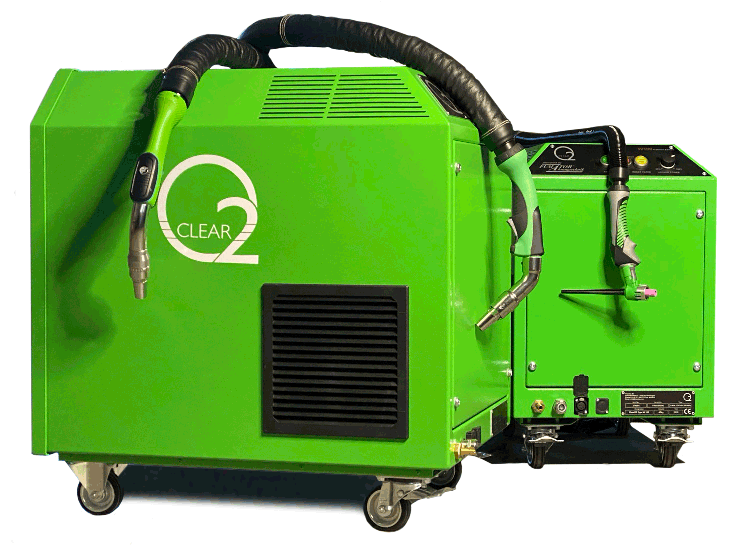

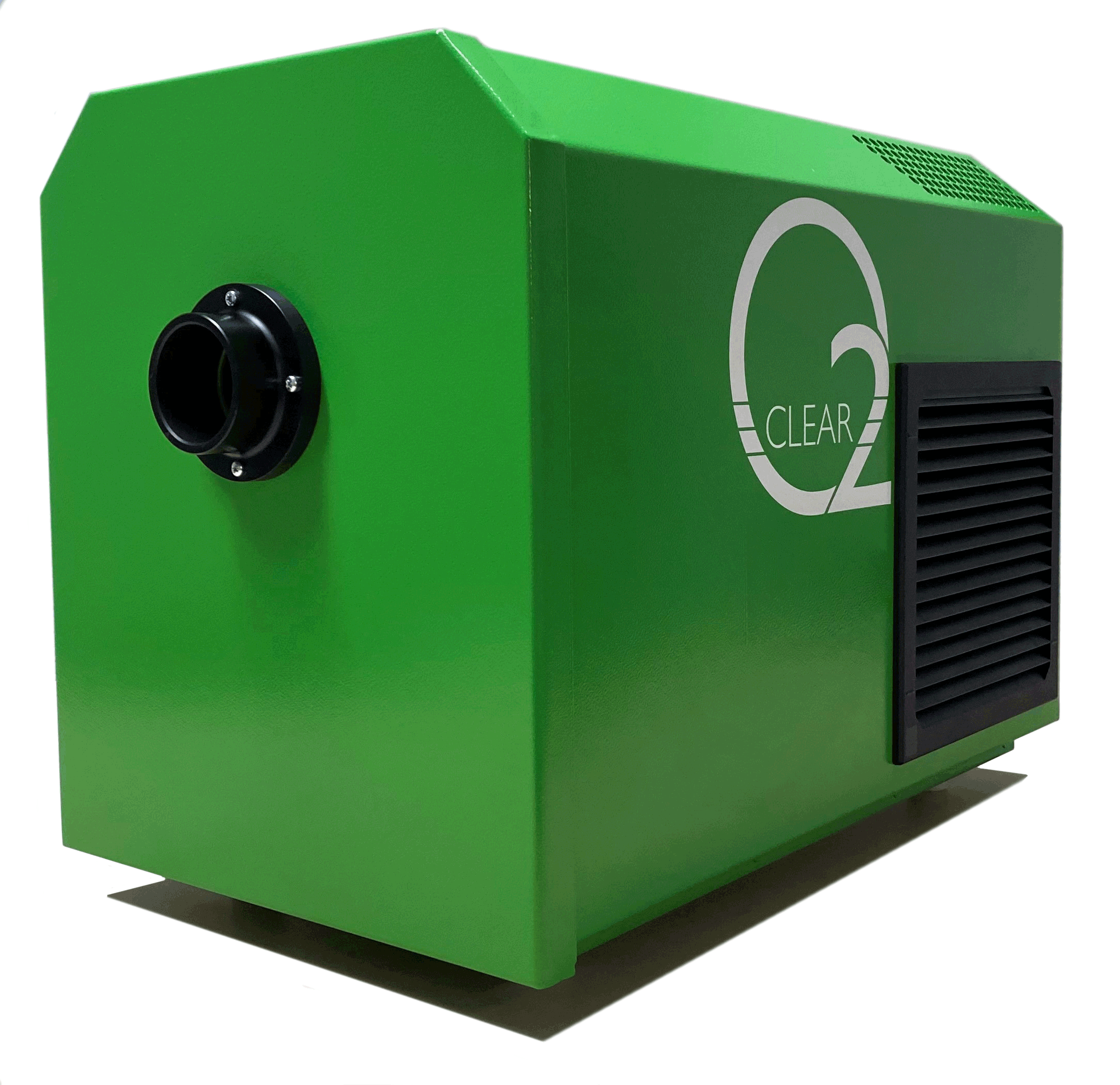

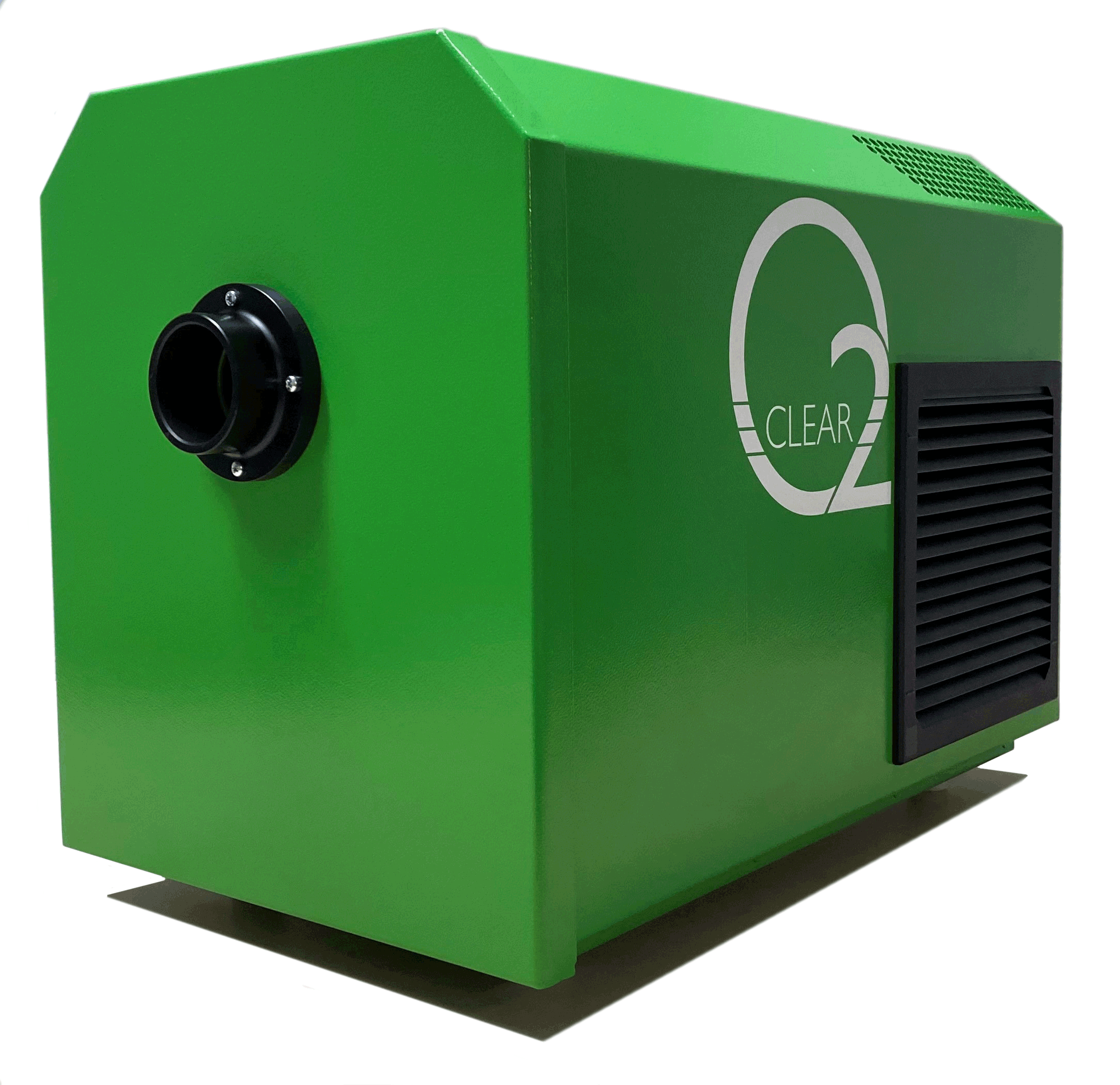

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

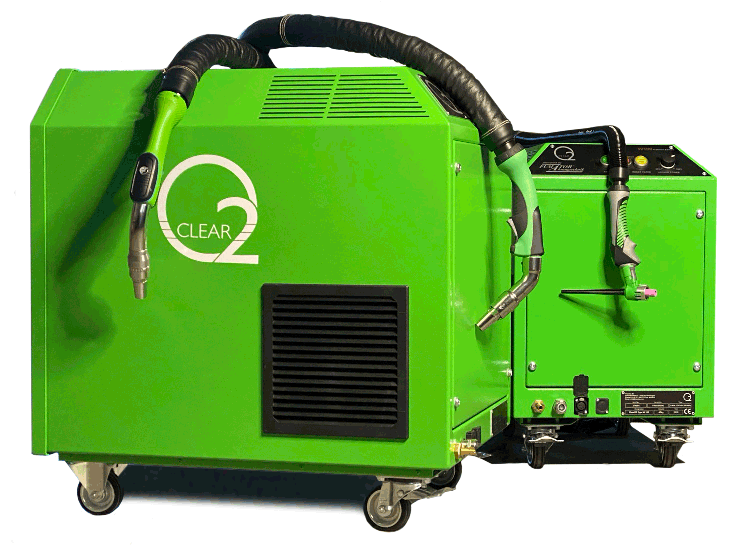

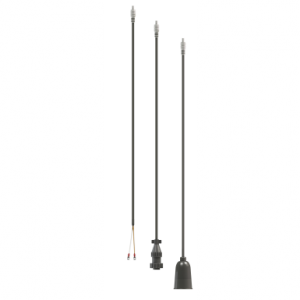

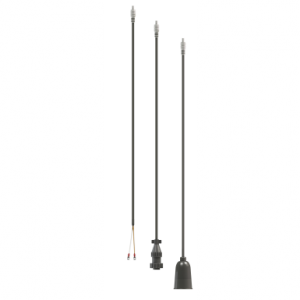

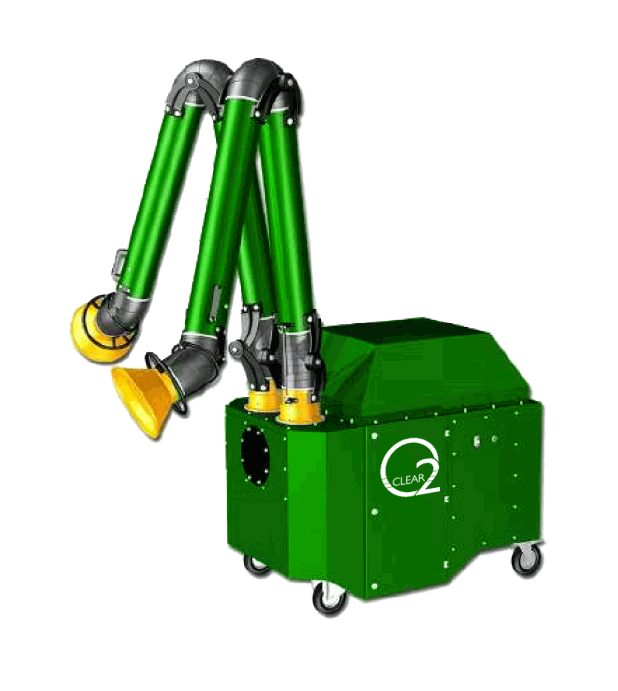

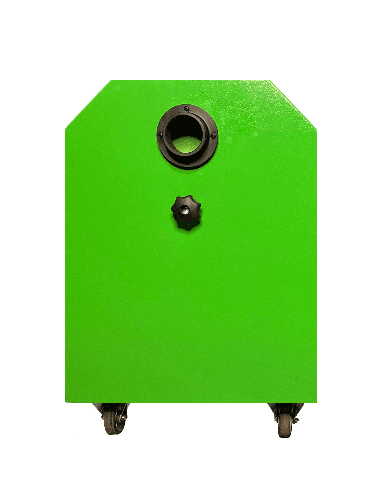

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

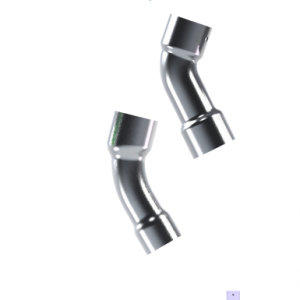

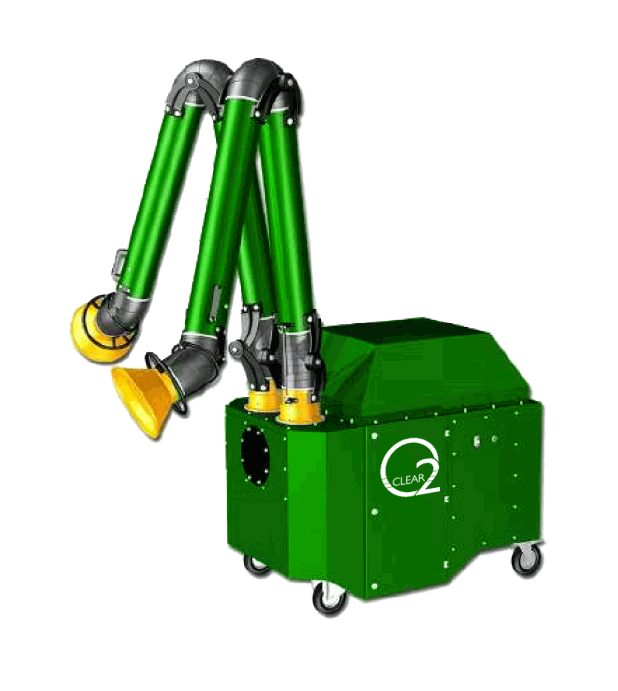

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

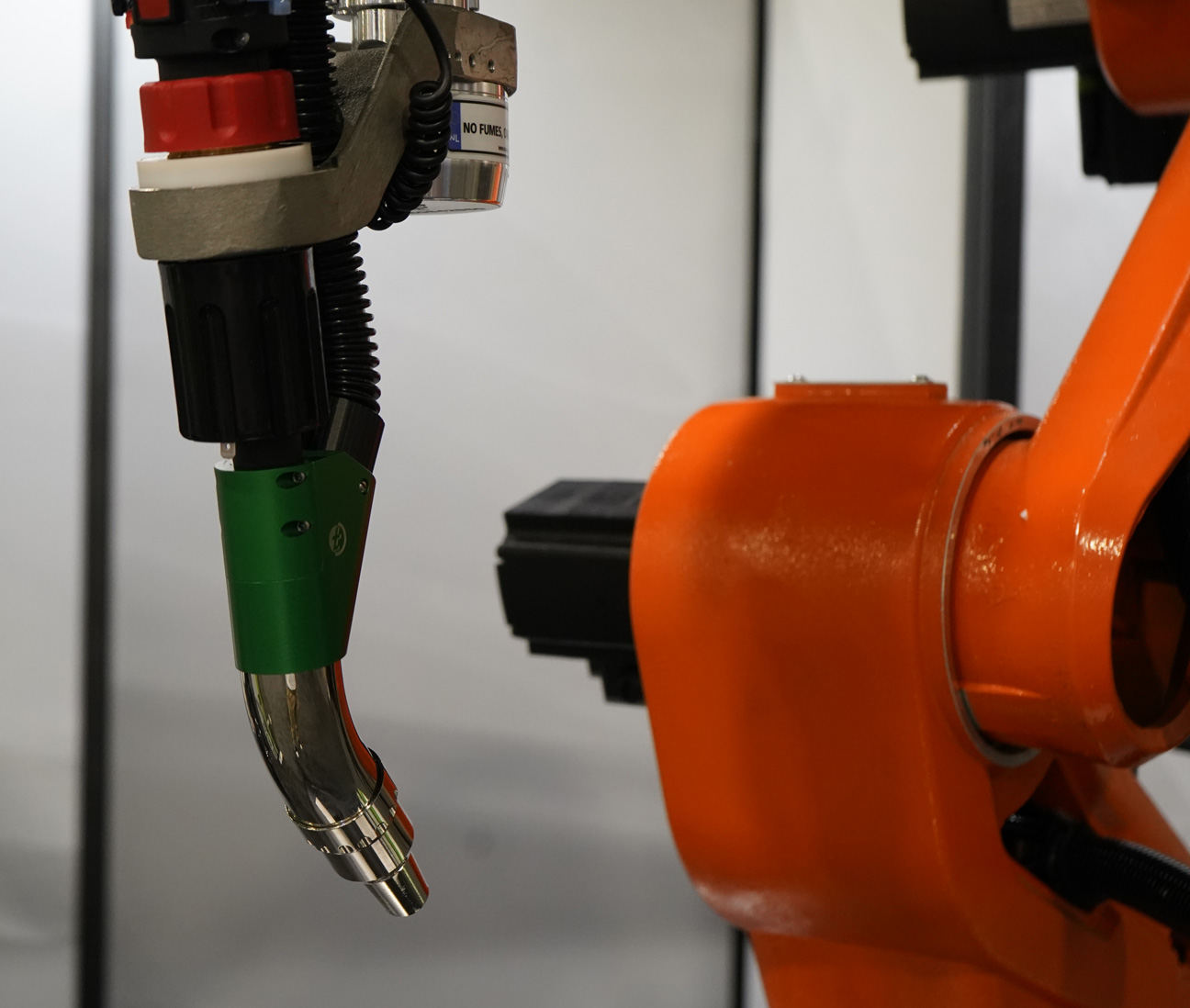

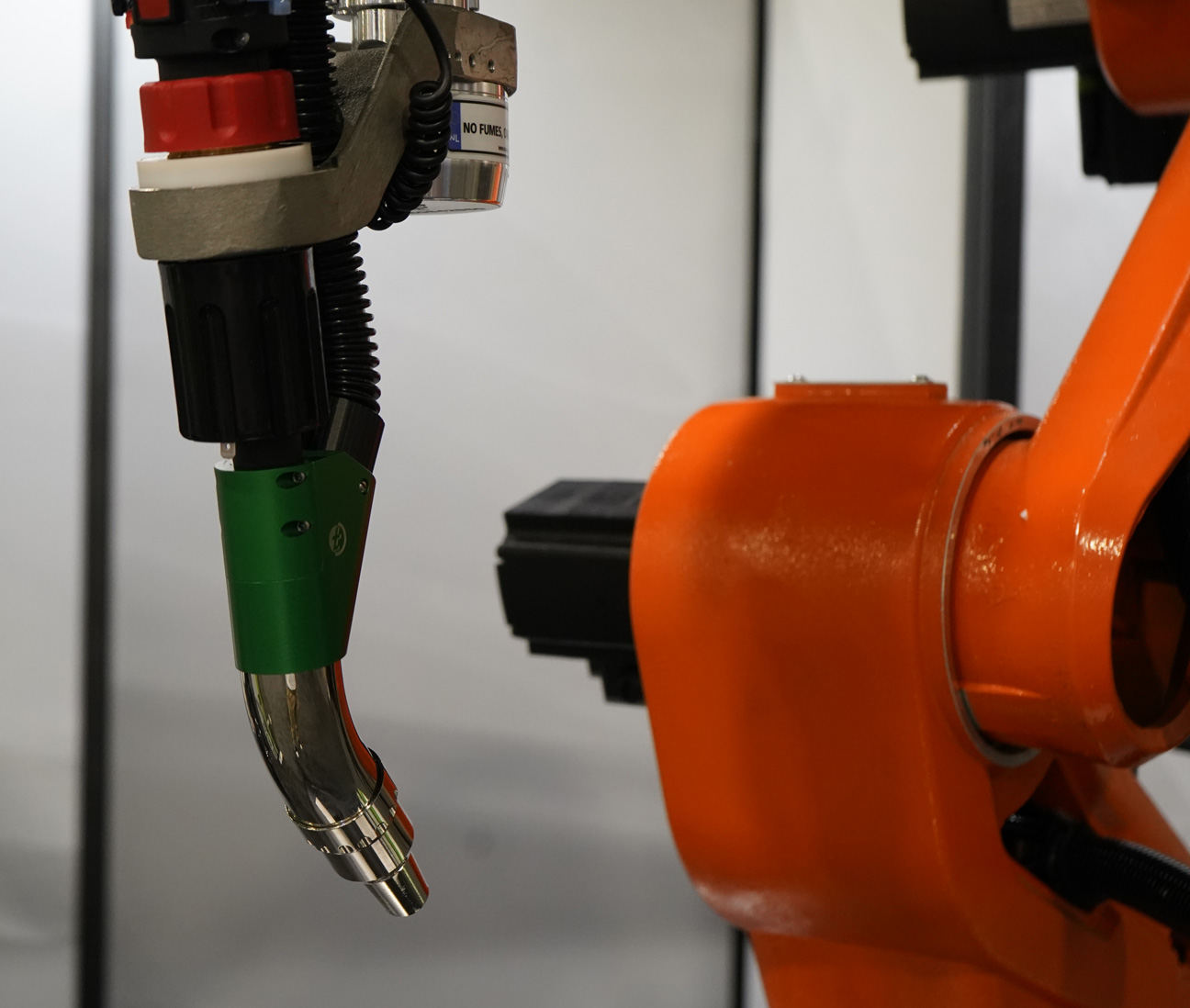

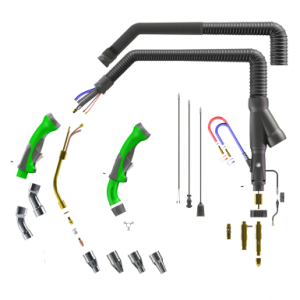

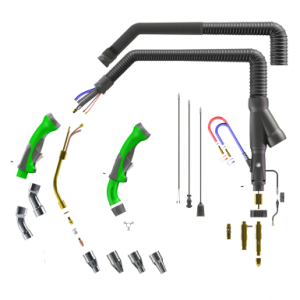

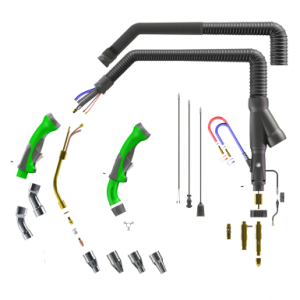

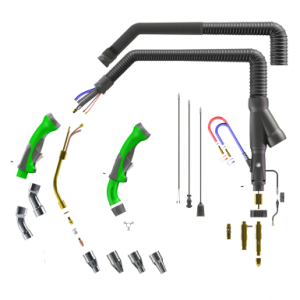

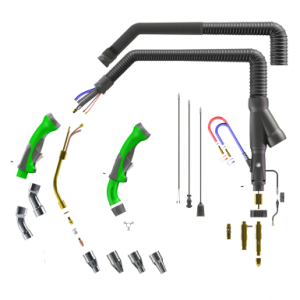

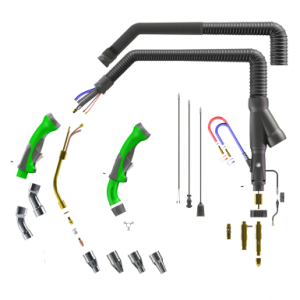

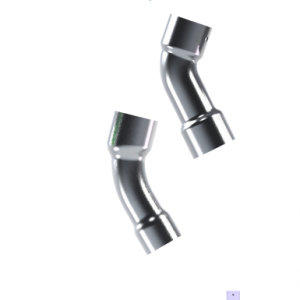

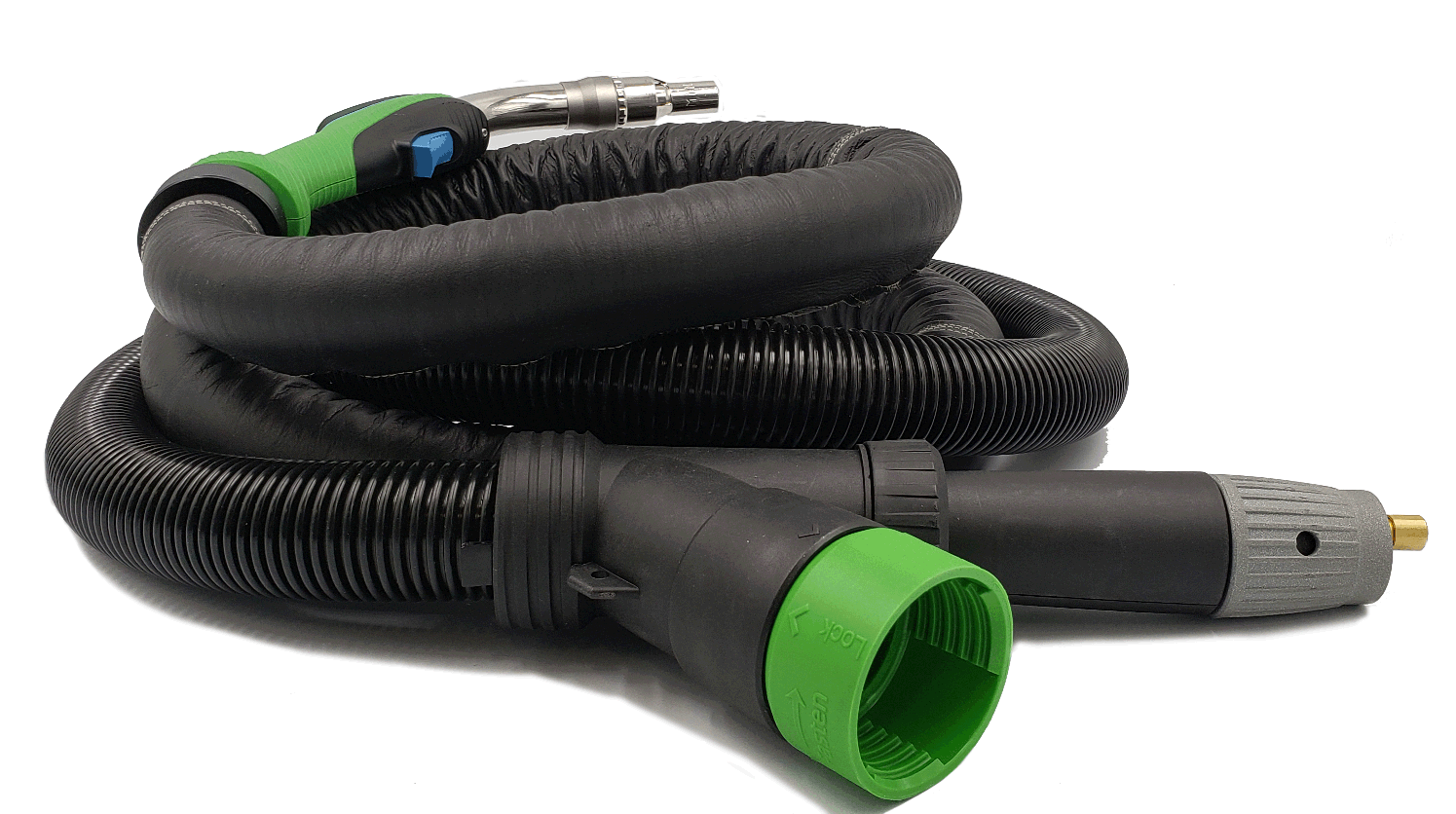

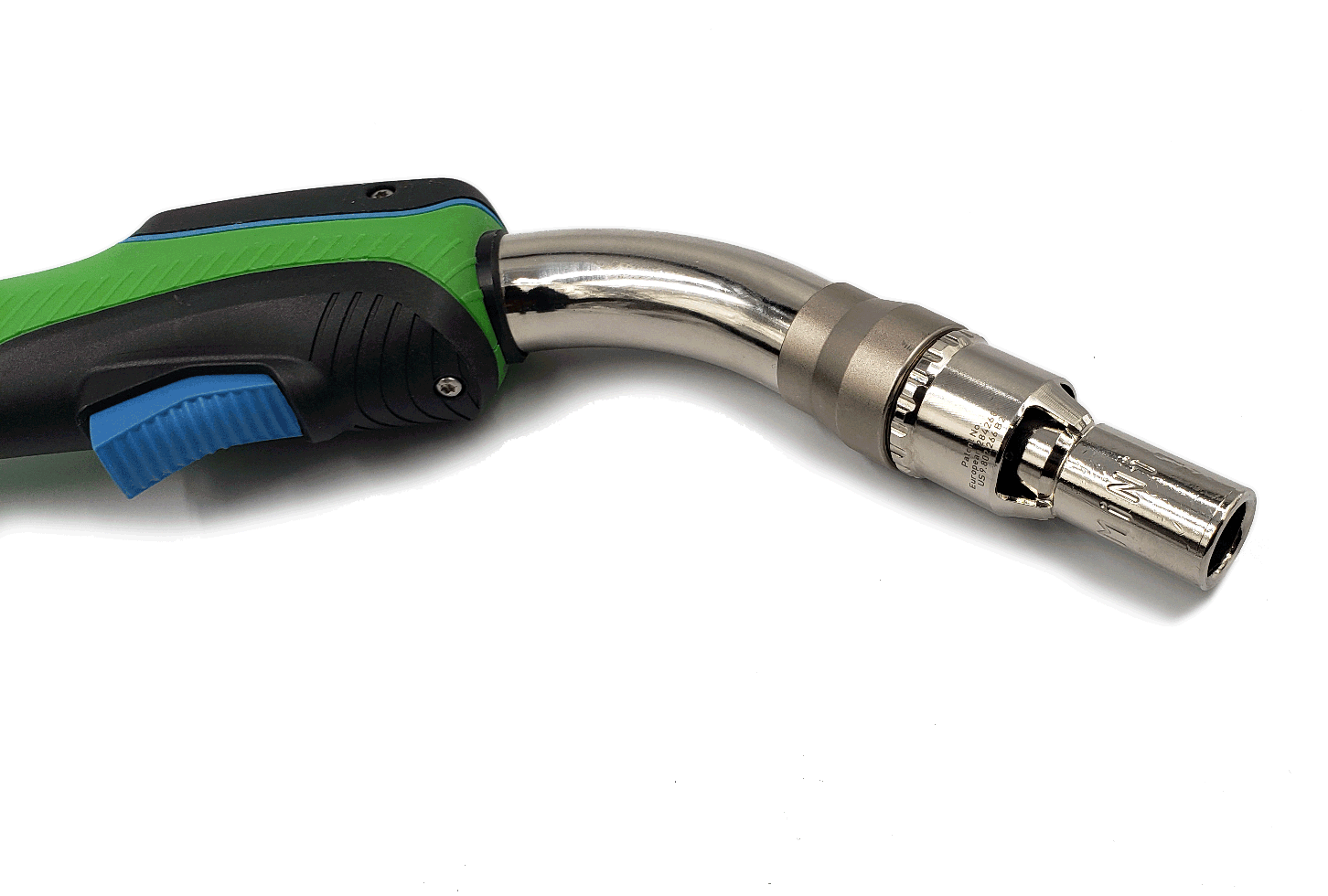

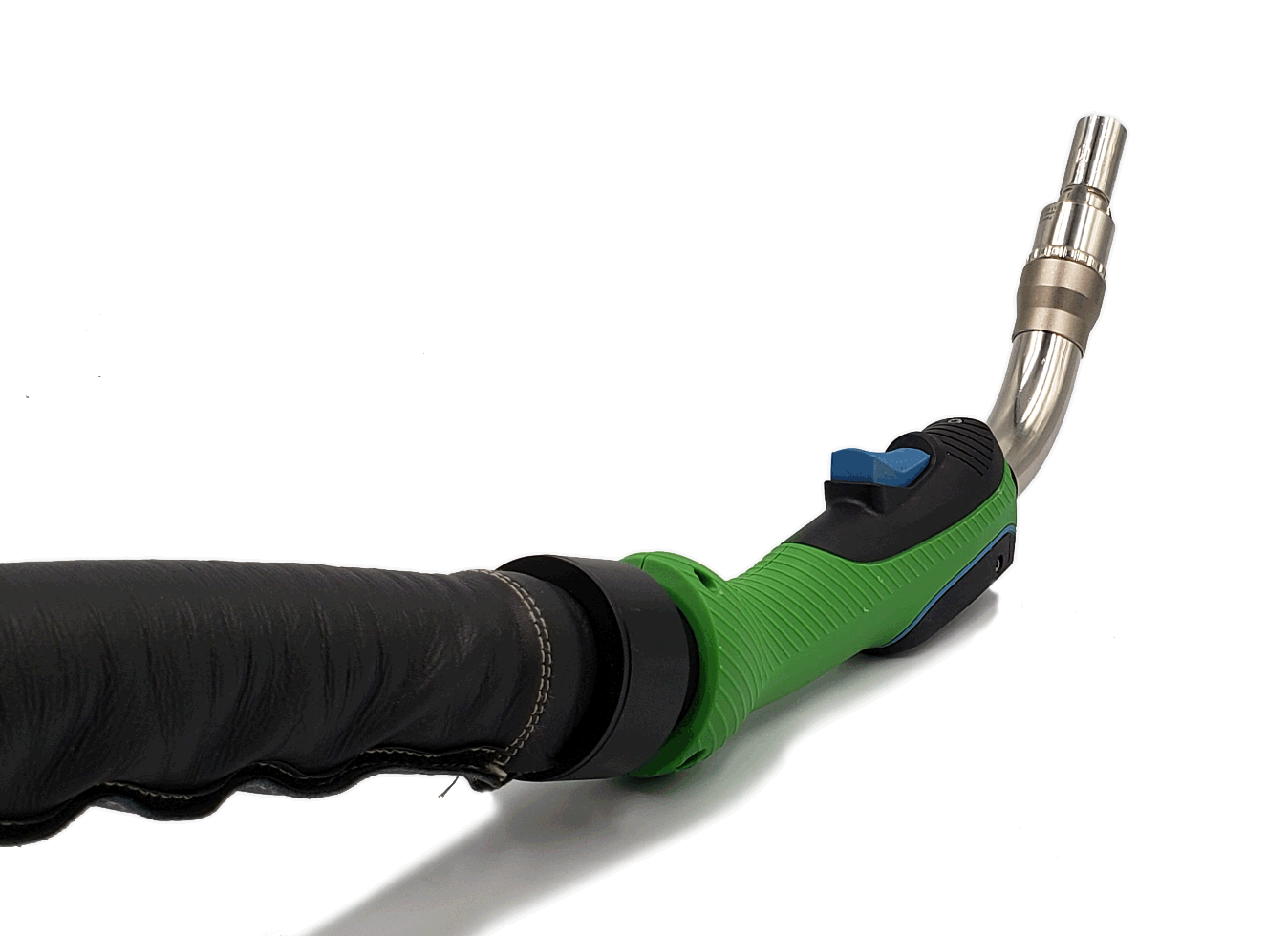

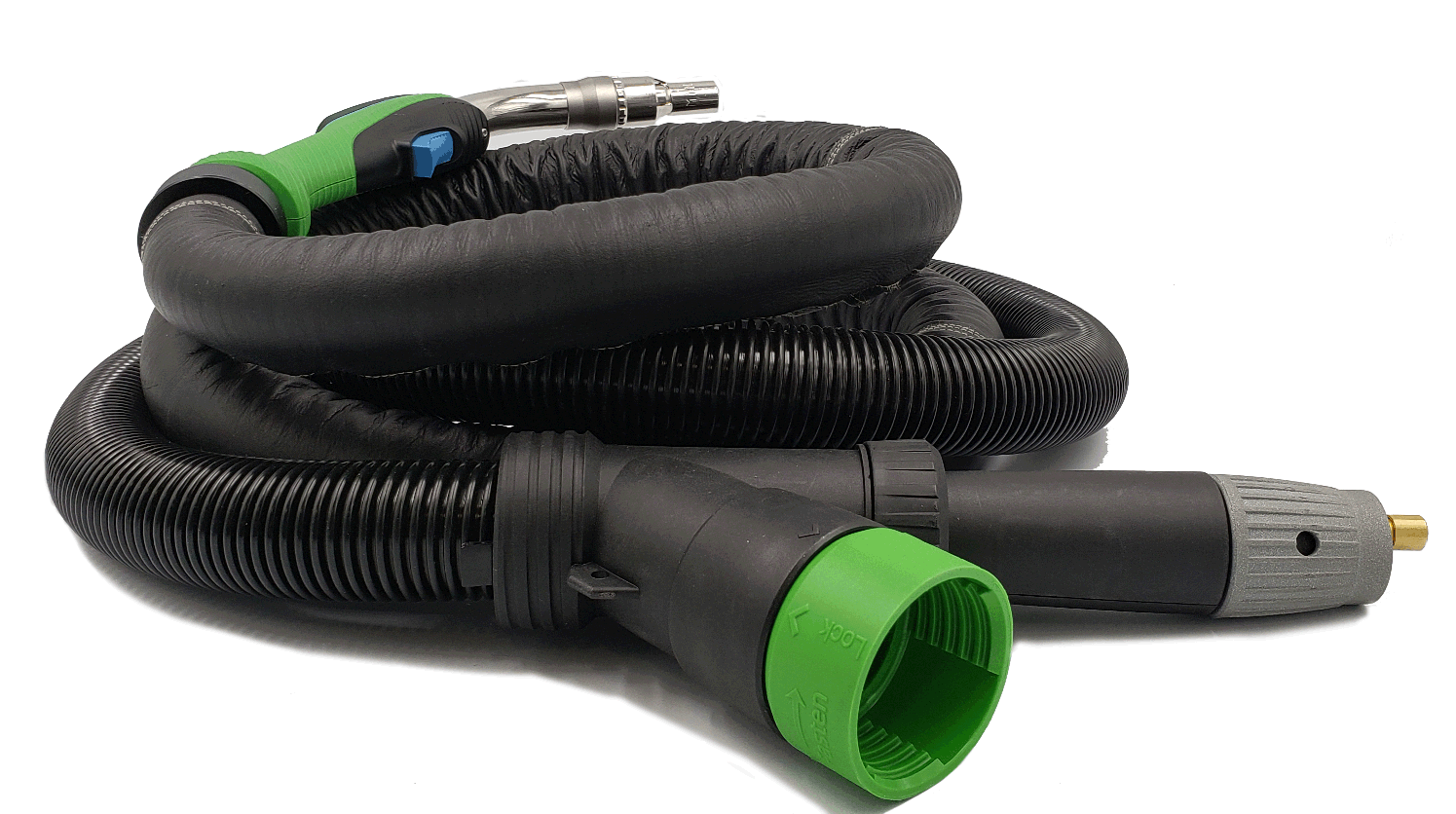

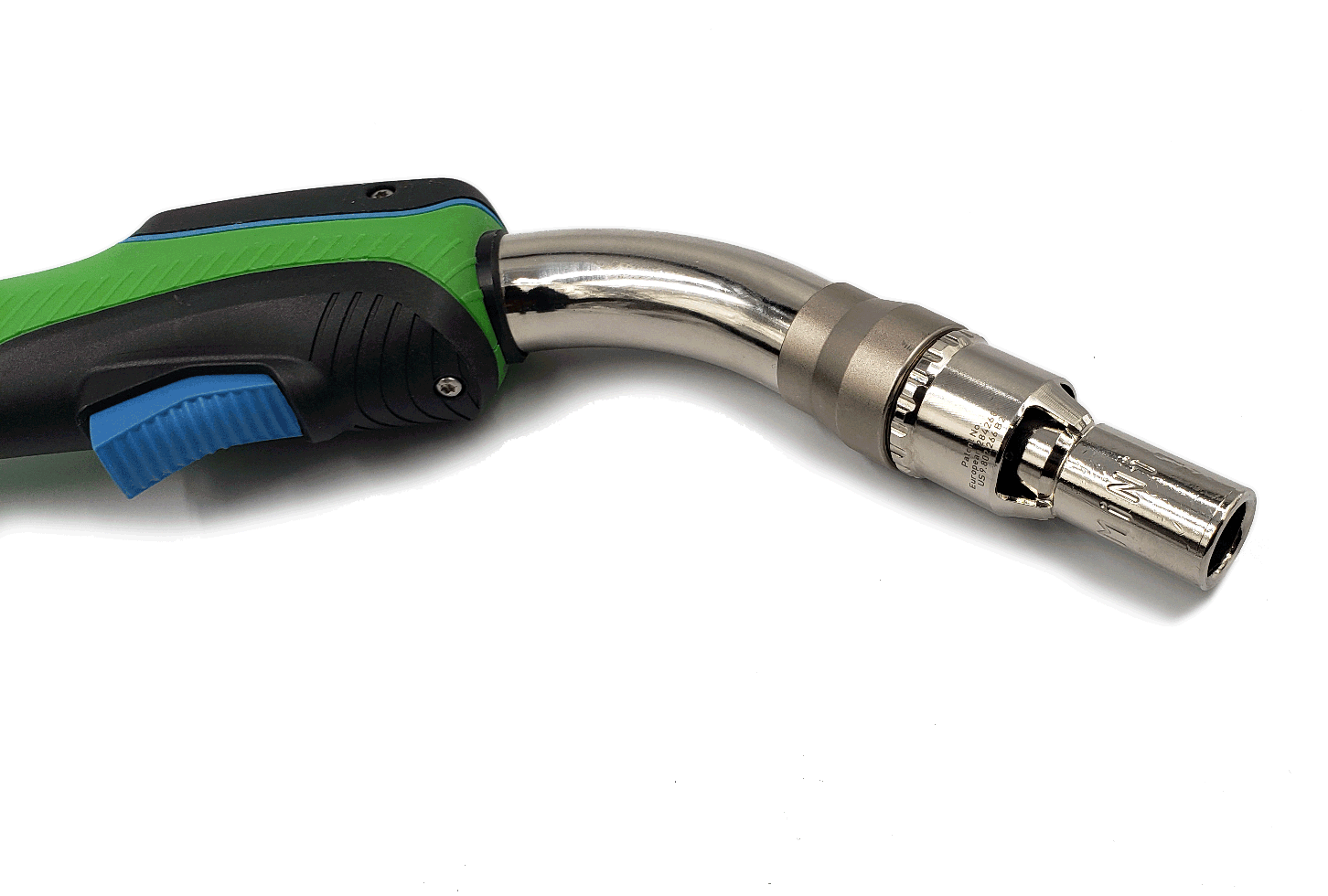

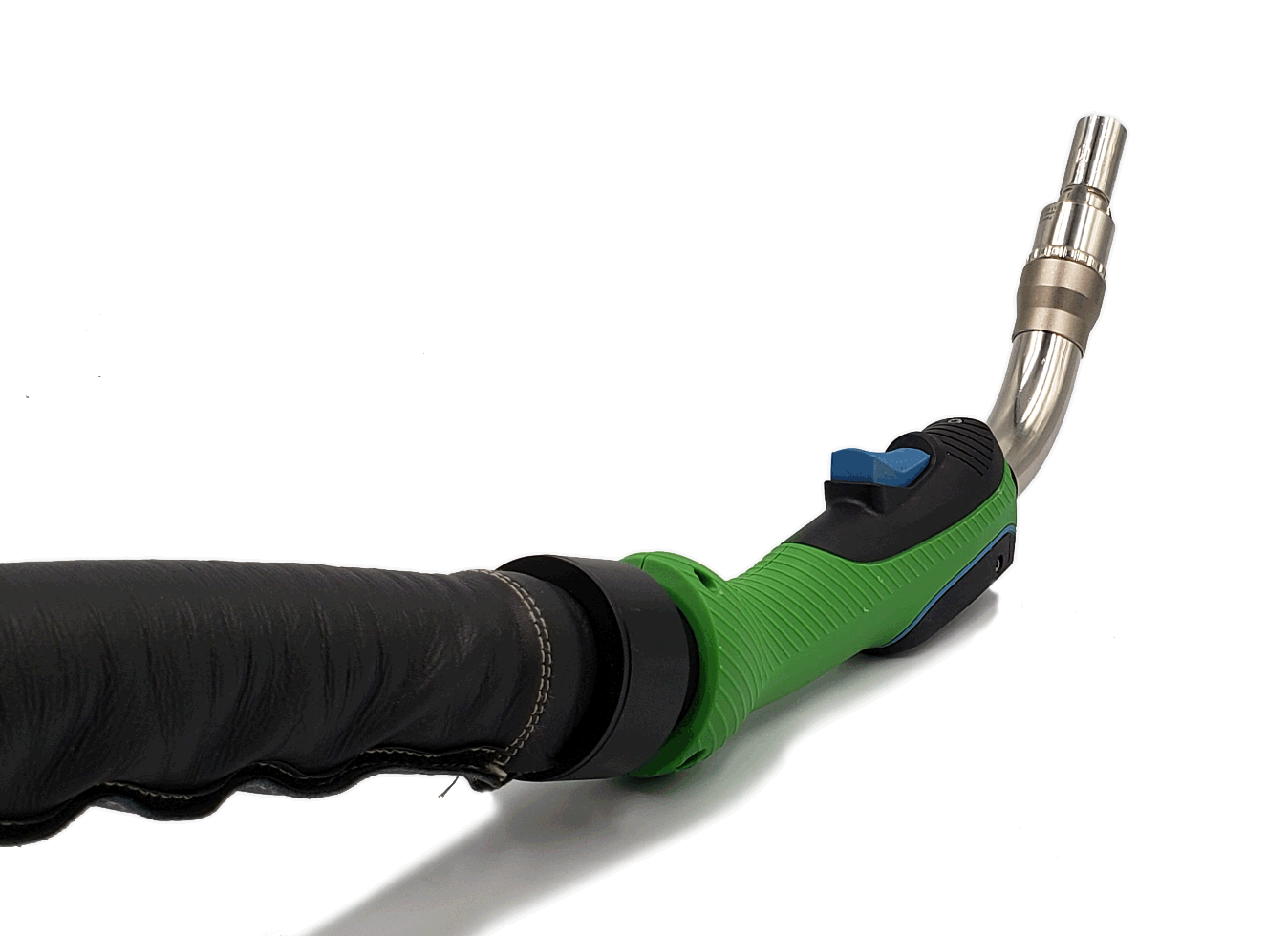

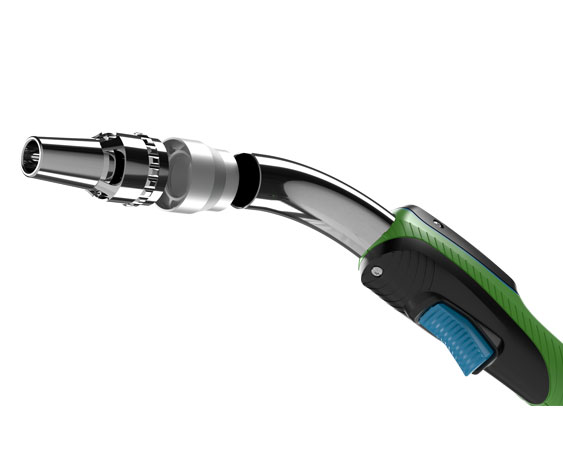

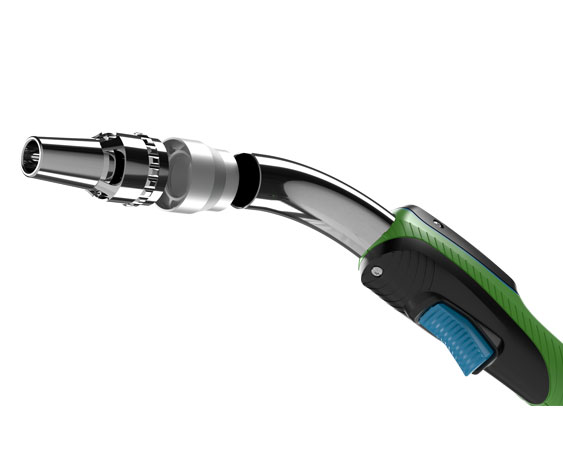

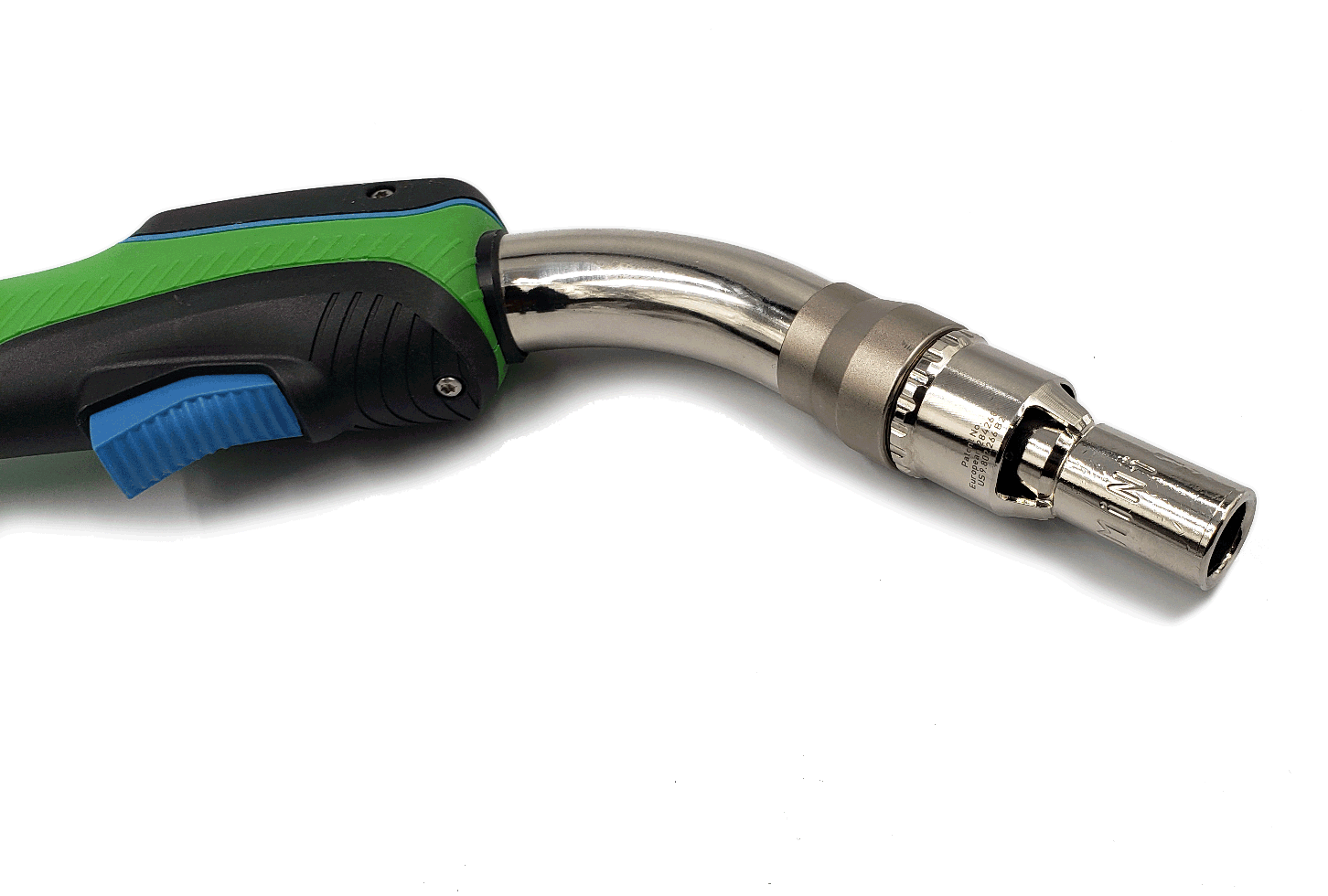

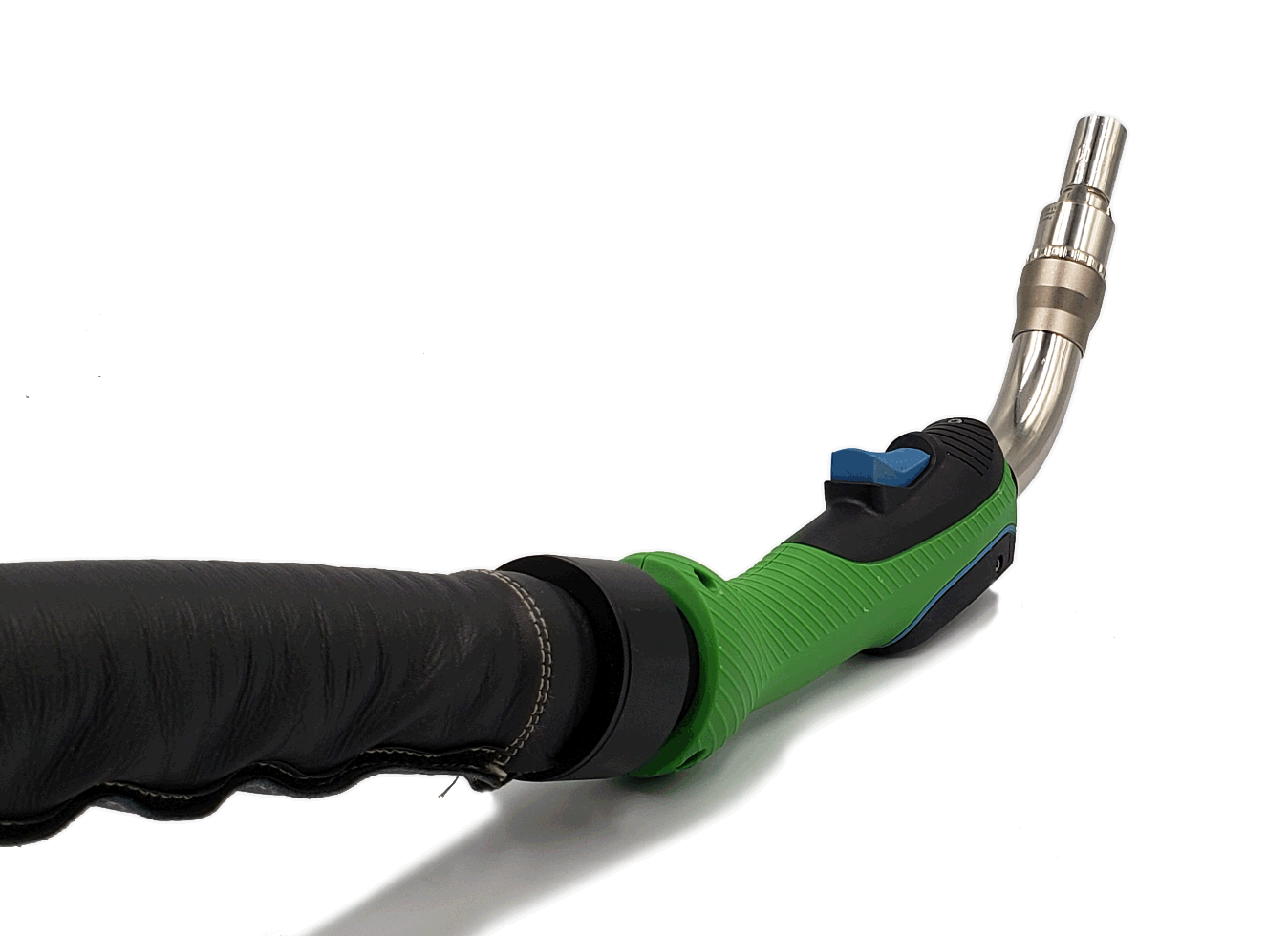

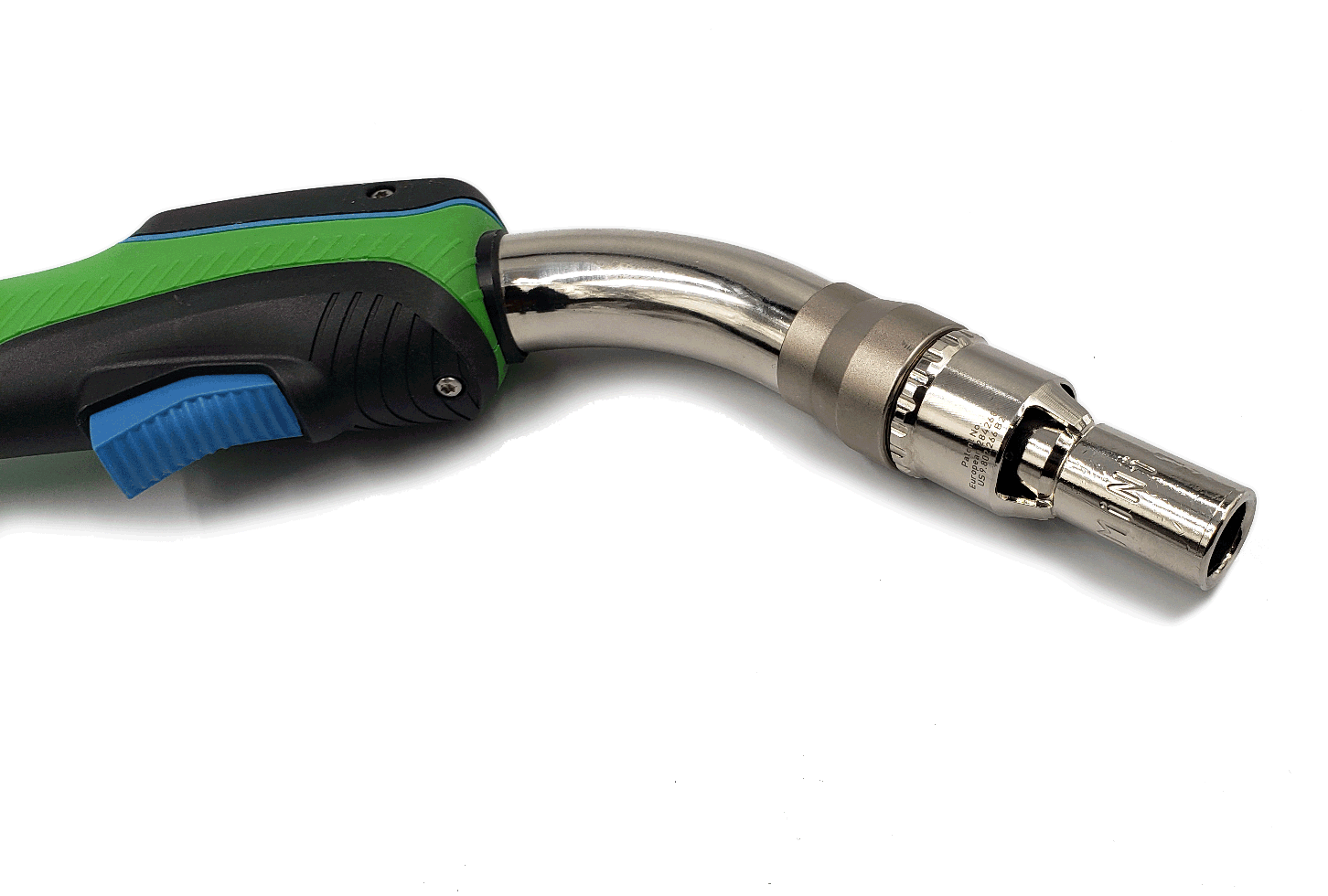

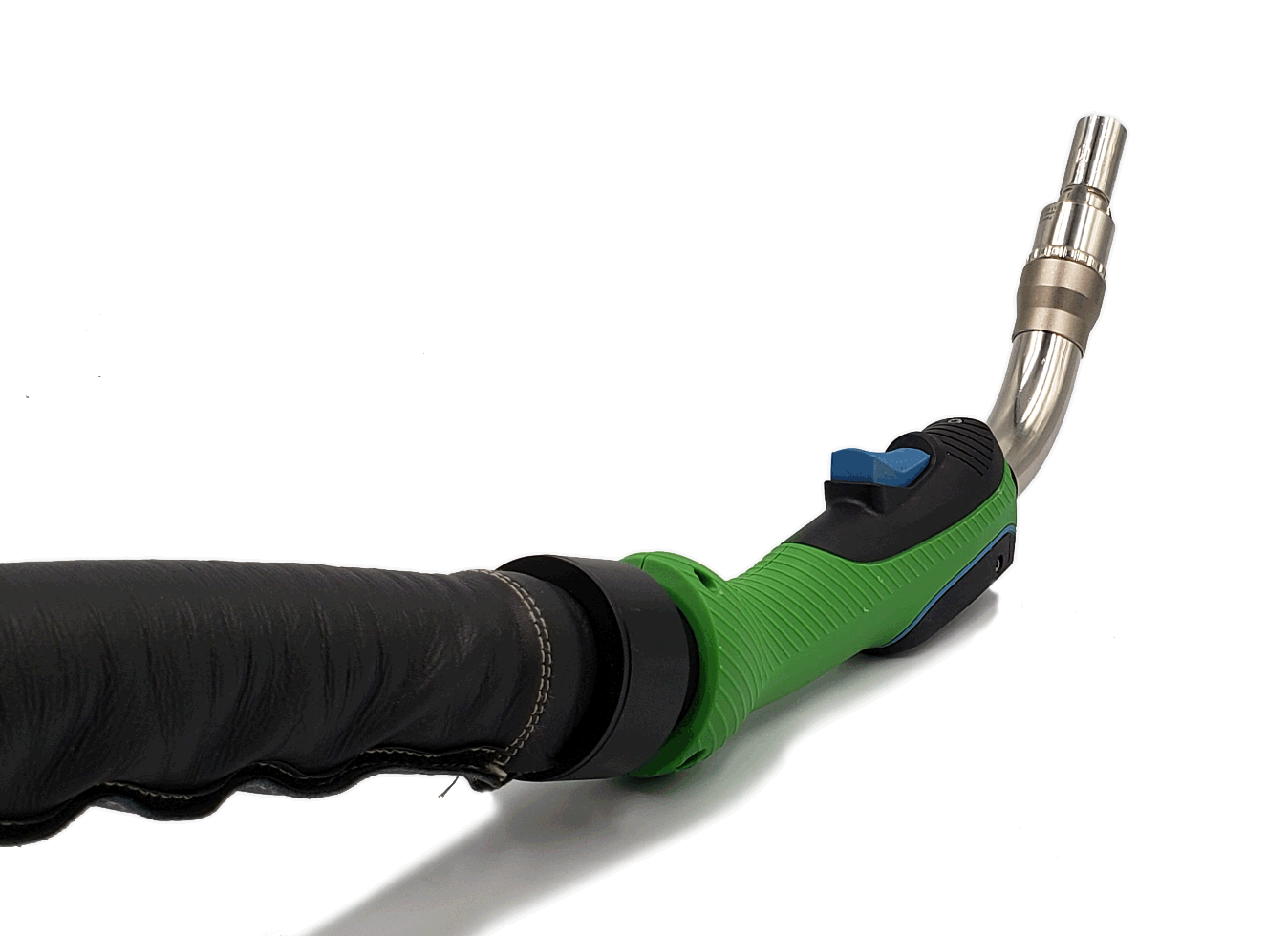

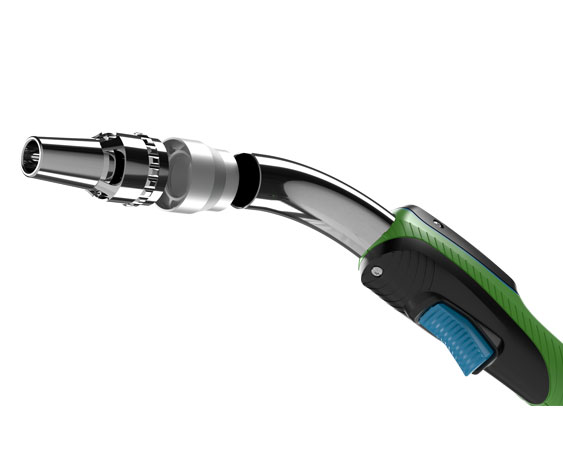

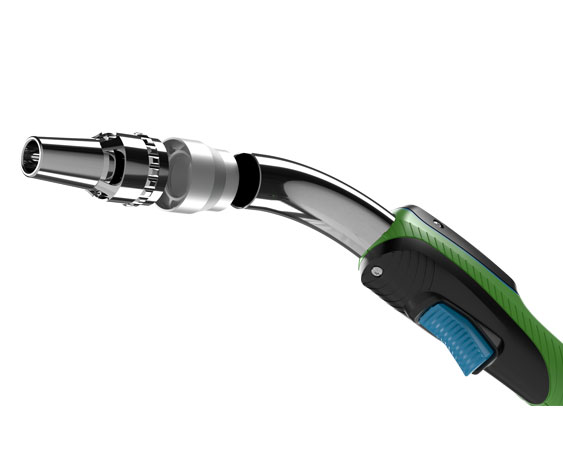

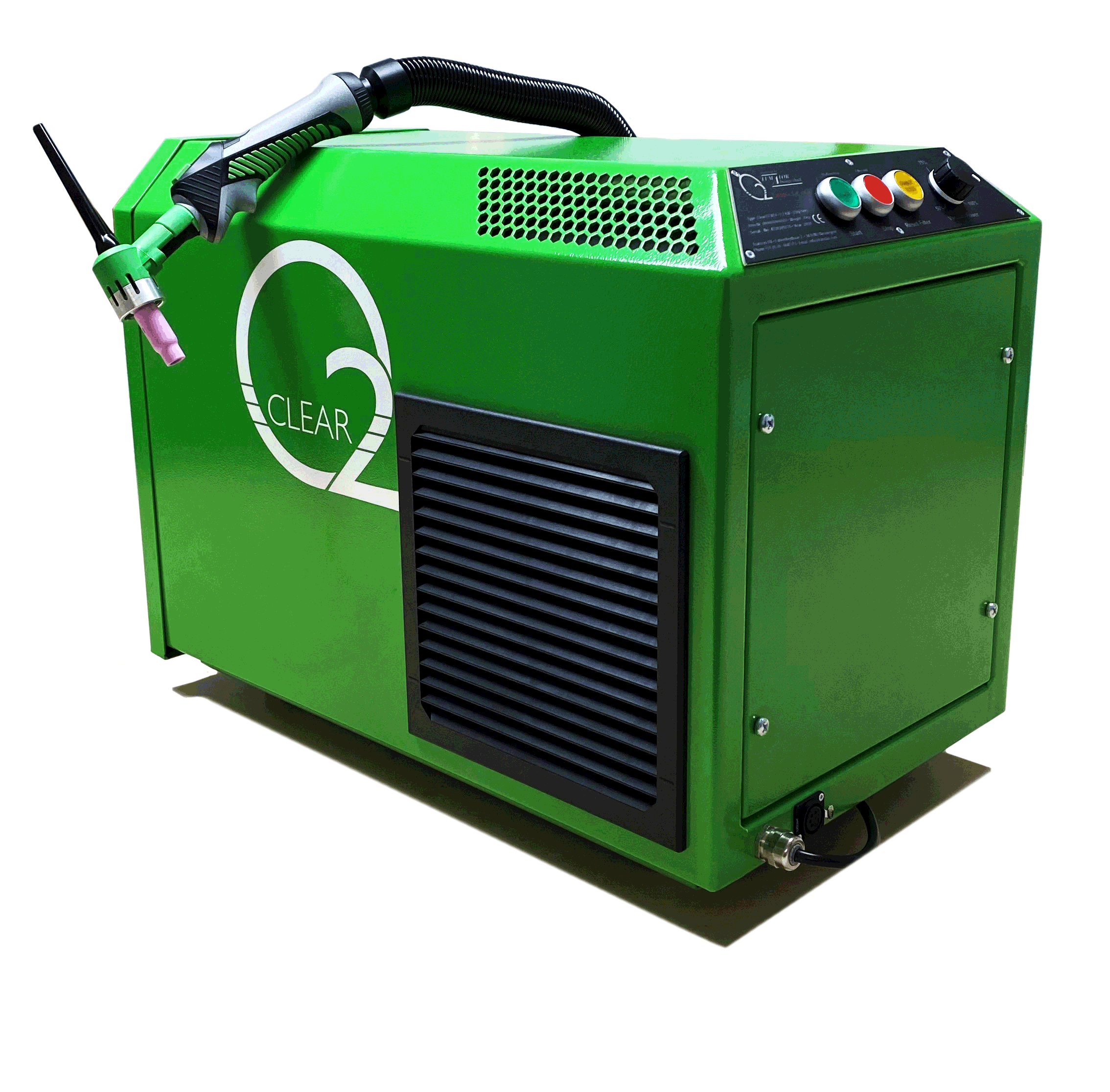

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding torches and welding equipment from Translas are distinctive in ergonomics, durability, performance, shape, and appearance.

Translas Canada Industries Ltd.

Unit 5, 1099 Commerce Way

Woodstock, ON, N4V 0A2

Canada

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.

Welding fume extractor is an apparatus that reduces the noxious fumes produced from the welding process. It usually has vacuum and air filters to capture nasty pollutants, so the air is actually pretty clean.

The fumes from these are composed of hazardous materials such as metals, gases and particulates that can do serious damage to a system if inhaled long term. Specific to the area for capturing these fumes are fume extraction arms and portable fume extractor welders.

Welding fumes — not just a big P on the shop floor but a real health risk. Excessive exposure can result to:

Respiratory issues

Lung diseases

Metal fume fen

Long term disease such as asthma or chronic bronchitis

Reducing these risks to an almost non-existent level is what a weld fume extractor does for the health and safety of a worker.

Various welding fume extractors are available to provide the best fit for all applications;

1. Portable Fume Extractor- Welding units

Small scale and mobile, ideal for home smelt shop or field welding jobs. They are very flexible, simple to deploy.

2. Fume Extraction Arm

They are the stationary units having arms adjusted to place above his welding location. Perfect for the ambitious craftsman.

3. Integrated extraction MIG welding gun

A MIG welding gun combined with a built-in fume extraction kit is pretty much a one-stop solution for welders.

The fume extraction arm – Perfect for focusing suction power where you need it. Captures the nastiness at the point of generation rather than just capturing fumes in general vs general ventilation systems.

The MIG welding gun with fume extractor is apparently the next big thing. A welder who pulls fumes away from the body while you are doing your work. It clears the work area and lowers health hazards.

Factors for Choosing an weld fume extractor is as follow:

Filtration Efficiency: Get HEPA filters for best particle removal.

Portability: Get a fume extractor welding unit that is portable if mobility is one of your most important criteria.

Suction: Choose one with power to suck up your welding set up

Noise levels (quieter means better for the environment)

Filter Swapping: Opt for systems with easiest filters to change.

Welding fume extractor works properly

Change the Filters

Clean your suction to avoid any blockages.

Inspect the unit for wear and tear.

1. Improved Air Quality

Welding fume extractor for Clean air means Non harmful particles

2. Inclusion of Safety Measures

Less exposure fumes = less health risk.

3. Observance of Safety Norms

The Fume extractor, while welding, helps you to observe your work space as safe as possible.

4. Increased Productivity

More Clean and safer environment gives more Concentration & Speed

Portable fume extractor welding units are very effective for small to medium-size operations, as well Yes. Lightweight, portable and fantastic suction power for local fume extraction — good locally but not necessarily a one stop shop.

Although made for welding fume extractors for soldering, cutting etc that create noxious fumes can also be put to use.

Welding fume extractors take the particles where welding stands, filter them out, and therefore minimize an all around better experience on your environmental state in doing welding.

Absolutely. Saving the staff and also reducing the probability of medical, and regulatory cost in future by investing on a good welding fume extractor is actually that simple.

1. What is the best welding fume extractor for small workshops?

A portable fume extractor welding unit is ideal for small workshops due to its compact design and mobility.

2. How often should I replace the filters in my welding fume extractor?

It depends on usage, but generally, filters should be replaced every 3-6 months for optimal performance.

3. Can a MIG welding gun help with fume extraction?

Yes, a MIG welding gun with integrated extraction captures fumes right at the source, enhancing safety.

4. Are fume extraction arms adjustable?

Yes, most fume extraction arms are highly flexible and can be positioned as needed for effective fume capture.

5. Do portable fume extractors require regular maintenance?

Yes, regular maintenance like filter replacement and cleaning ensures efficient operation of portable fume extractor welding units.

Welding is a key process for a lot of industries however has its difficulties and one of the greatest is fumes. Well it’s the welding fume extractor for you. These tools are meant to increase air quality, provide workers with a safer working environment and raise output. In the following post we will break down all about welding fume extractors, advantages and why you need one for your workshop.