Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

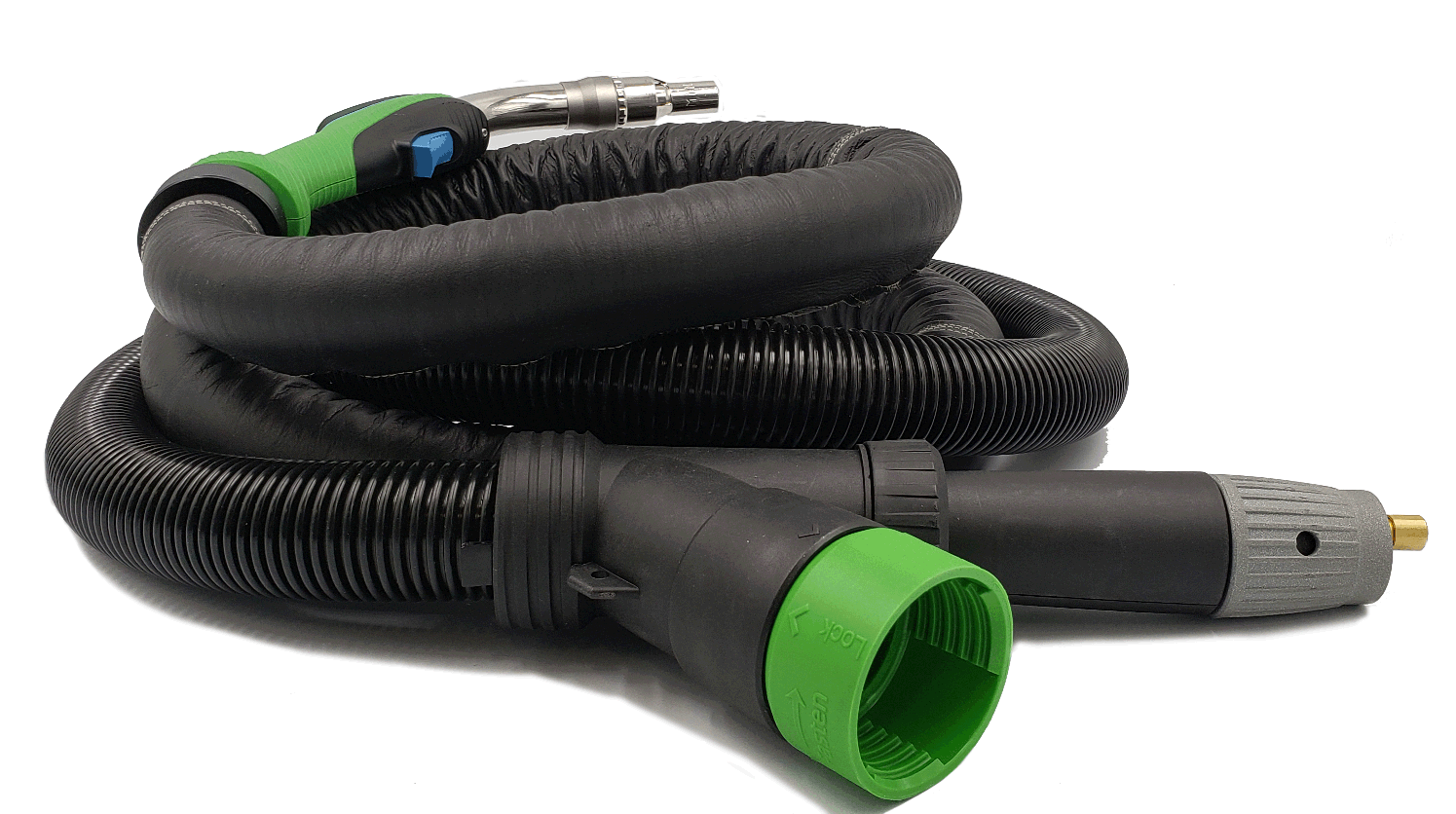

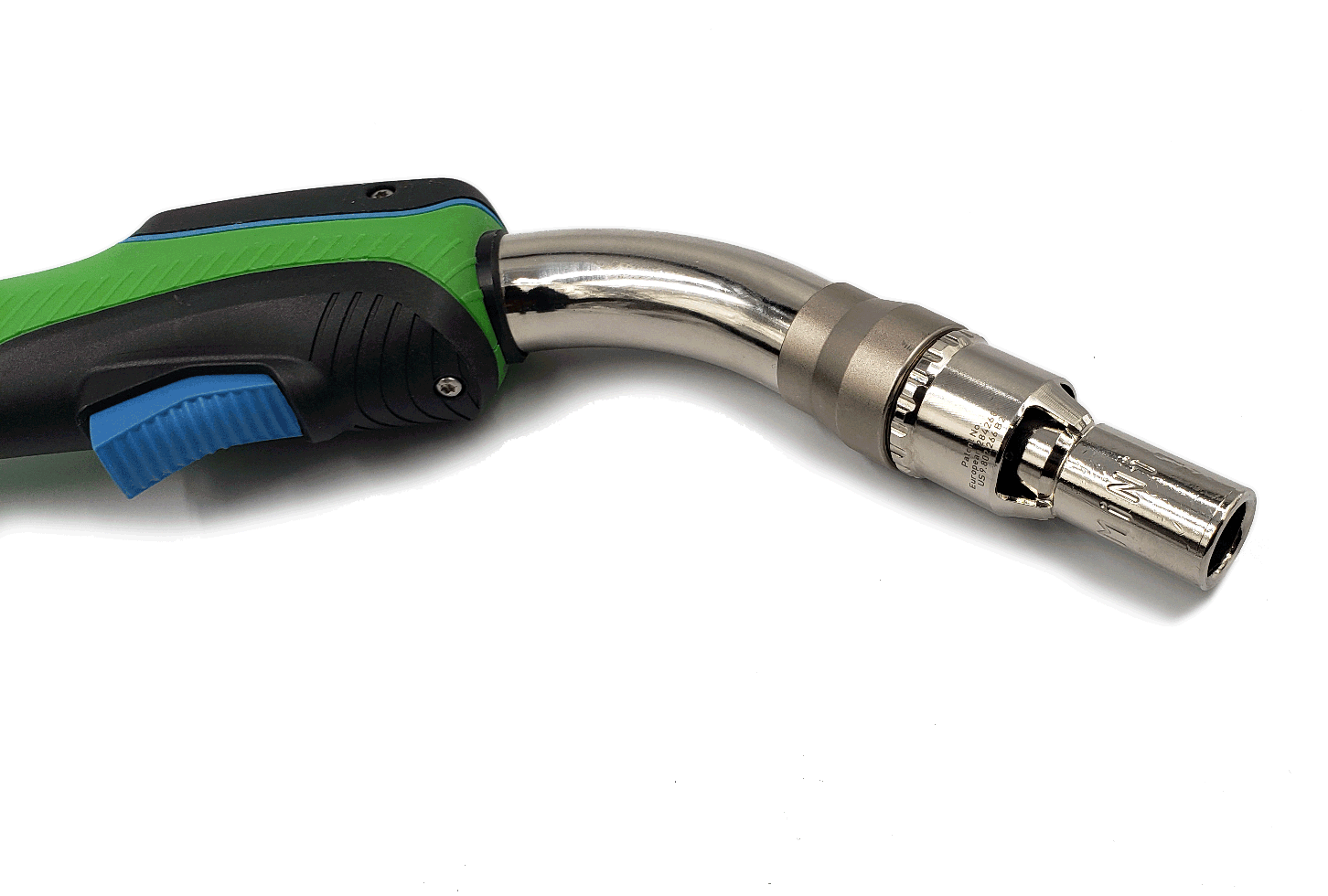

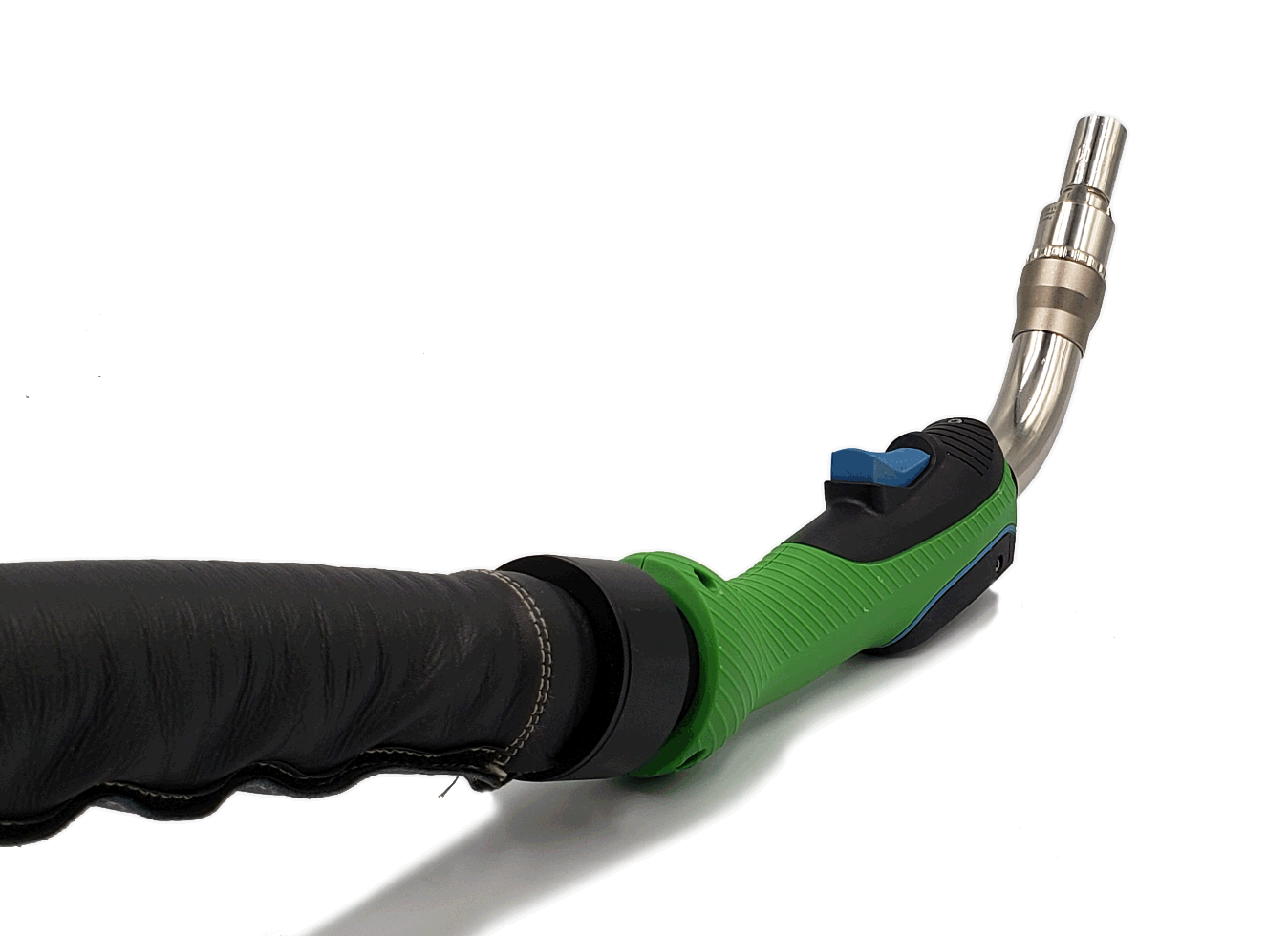

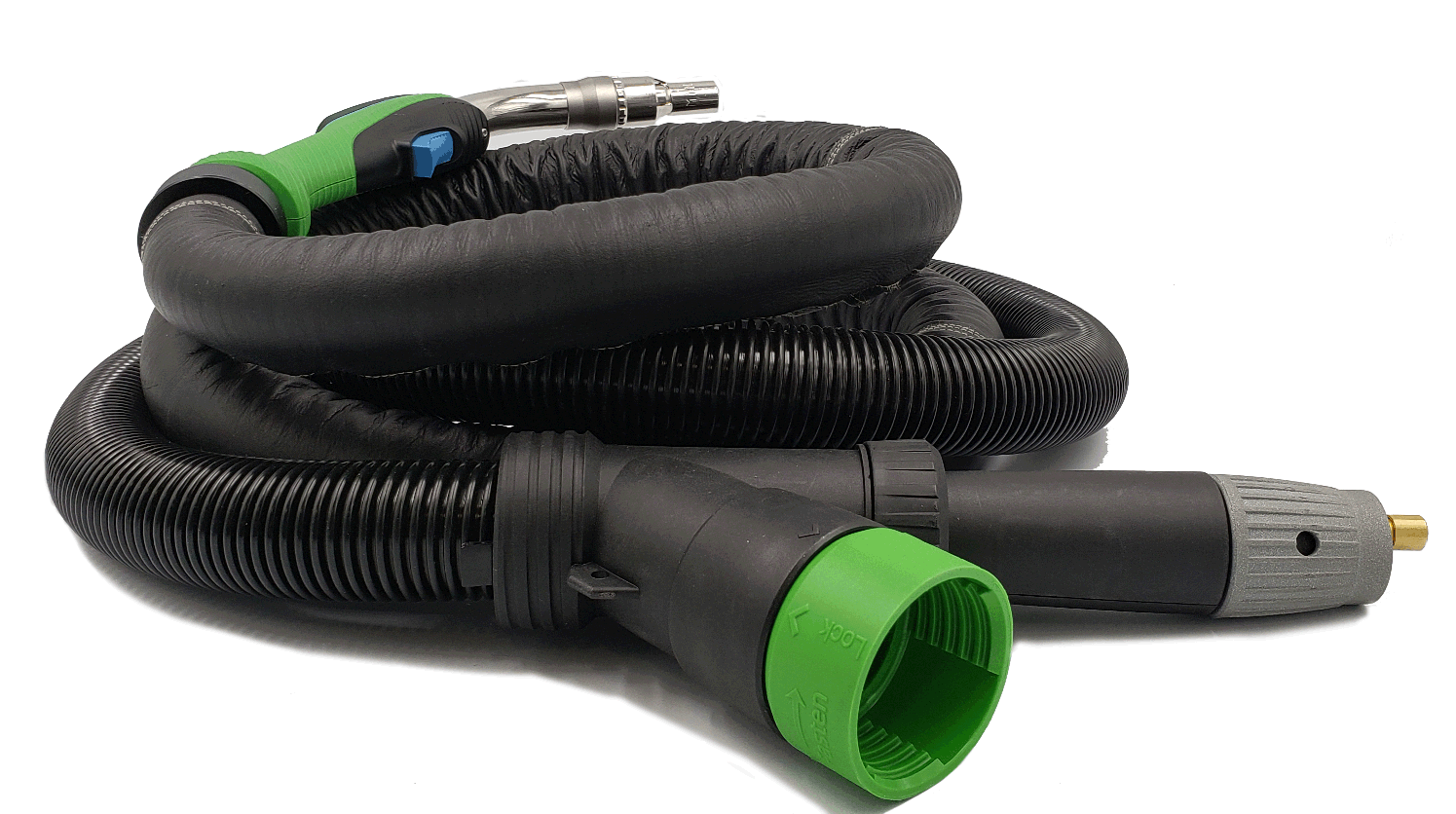

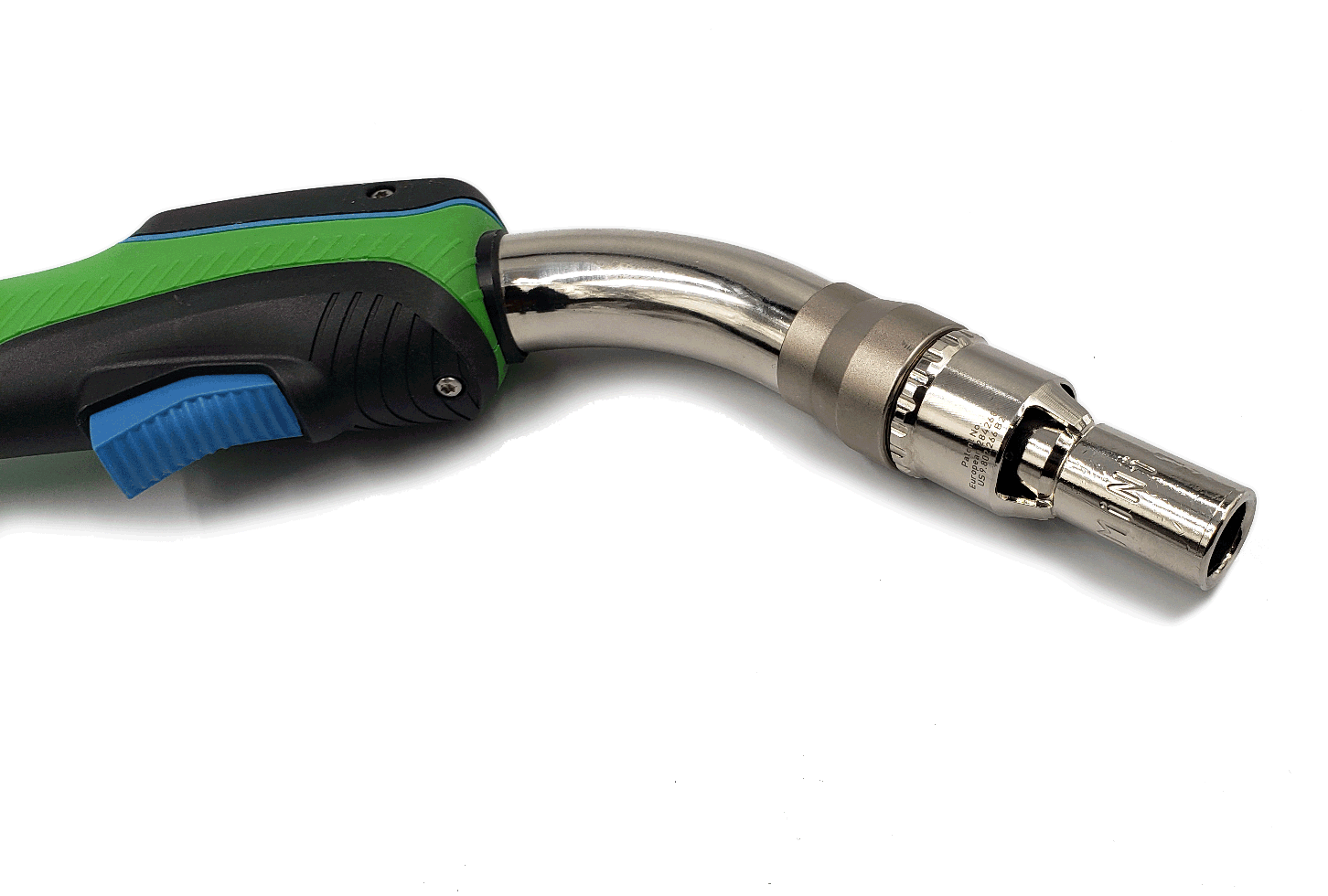

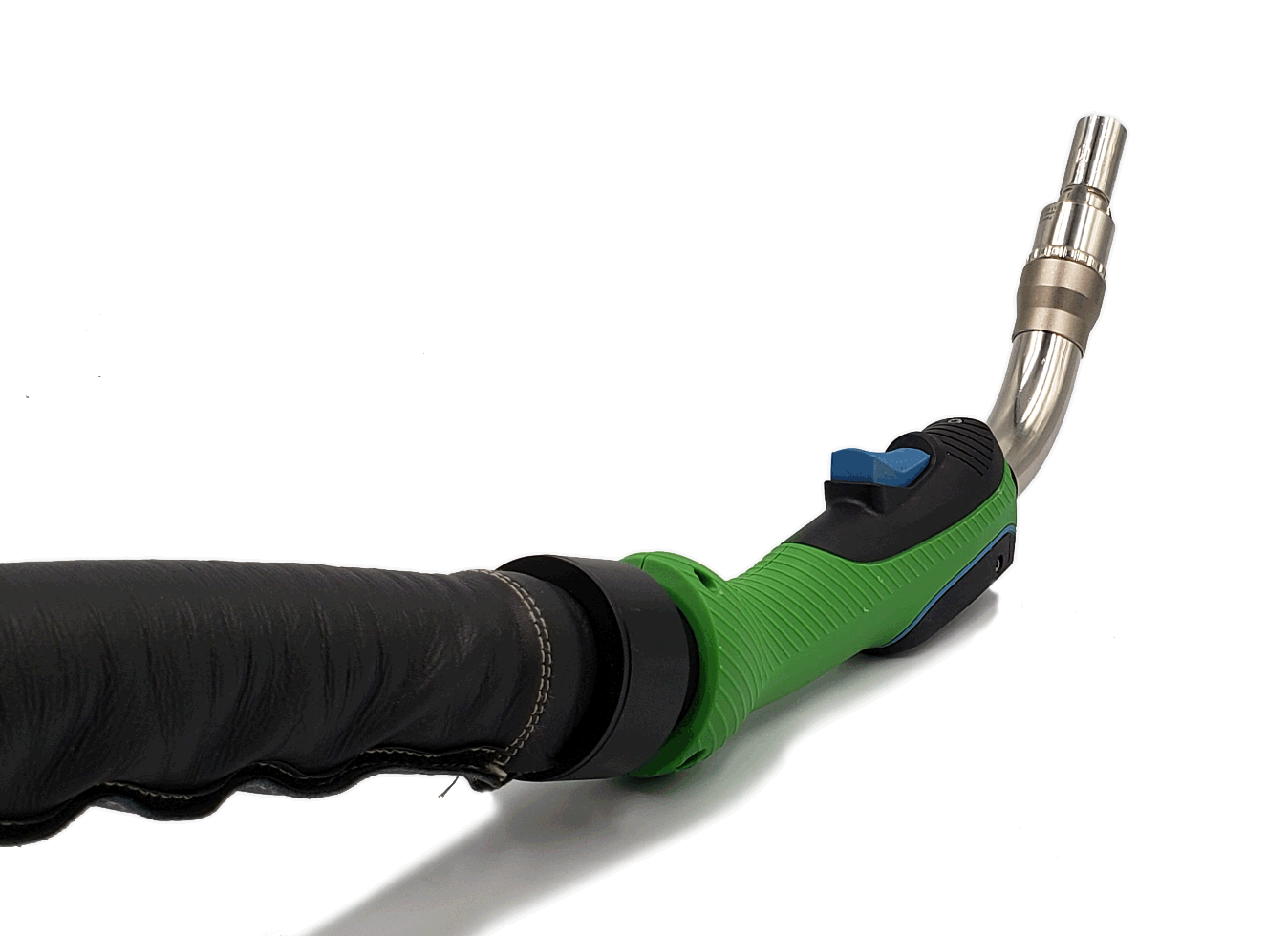

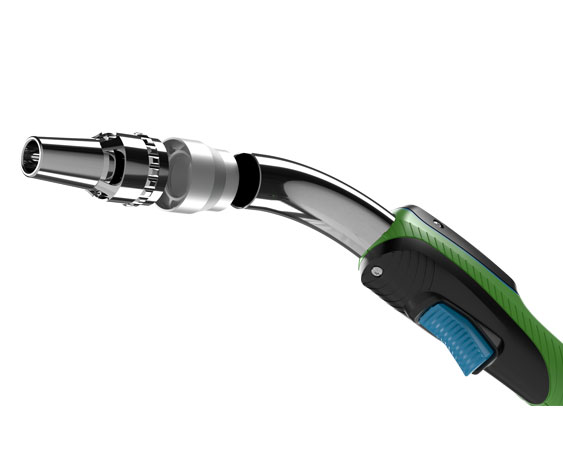

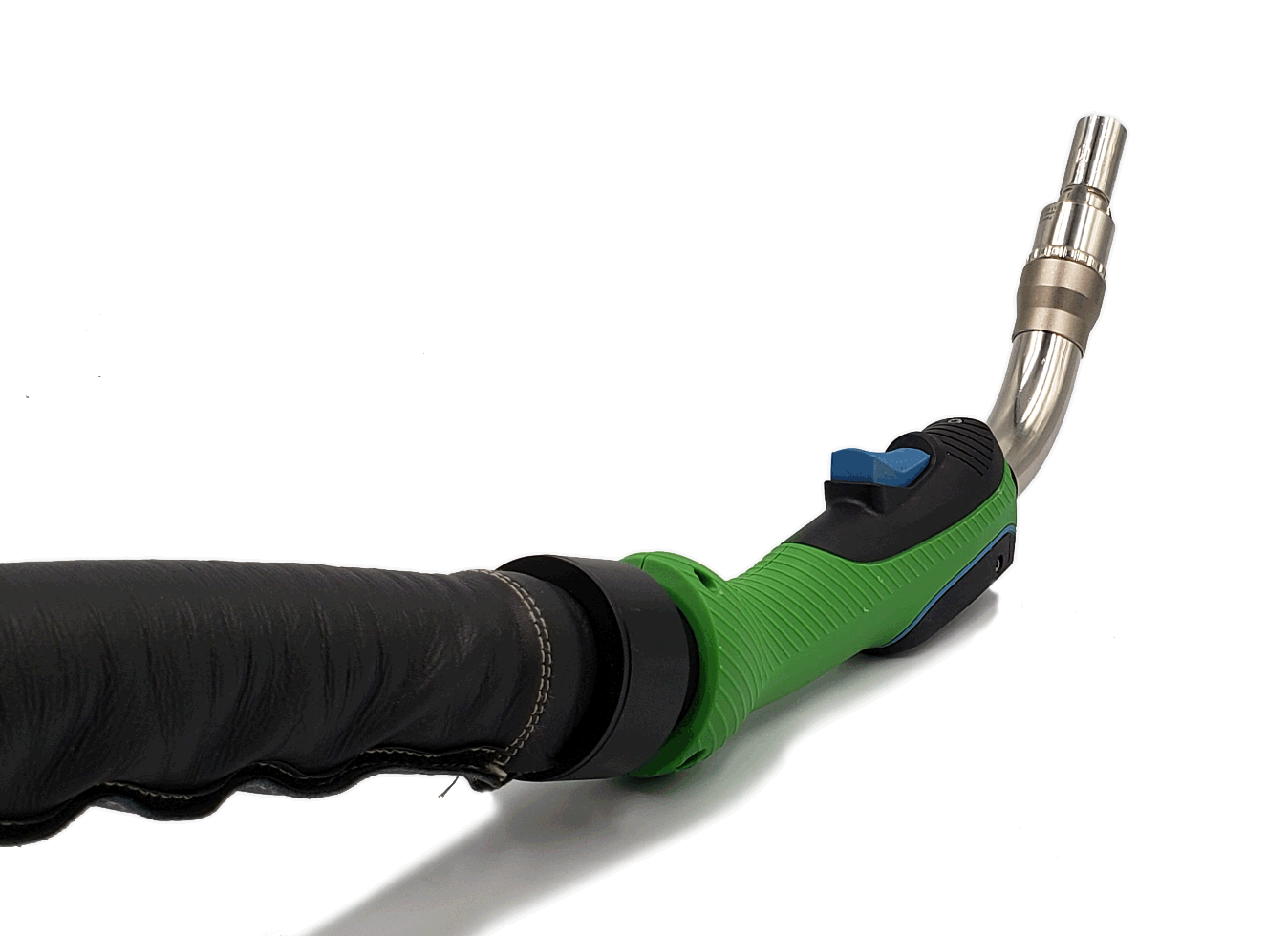

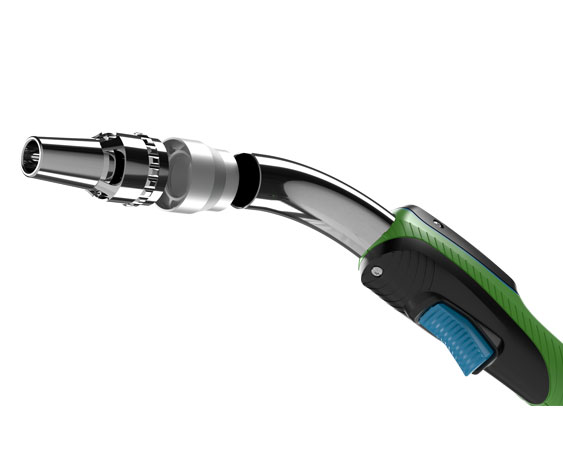

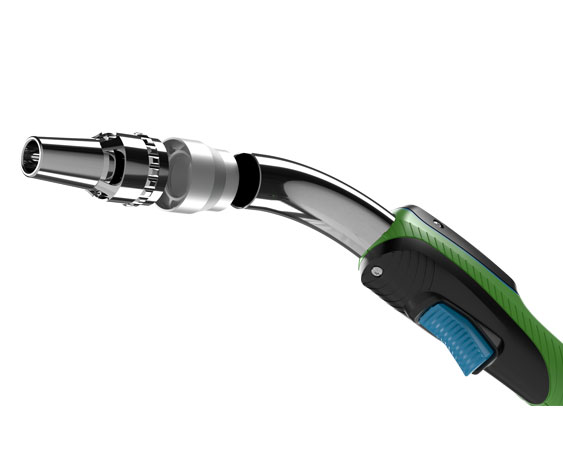

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

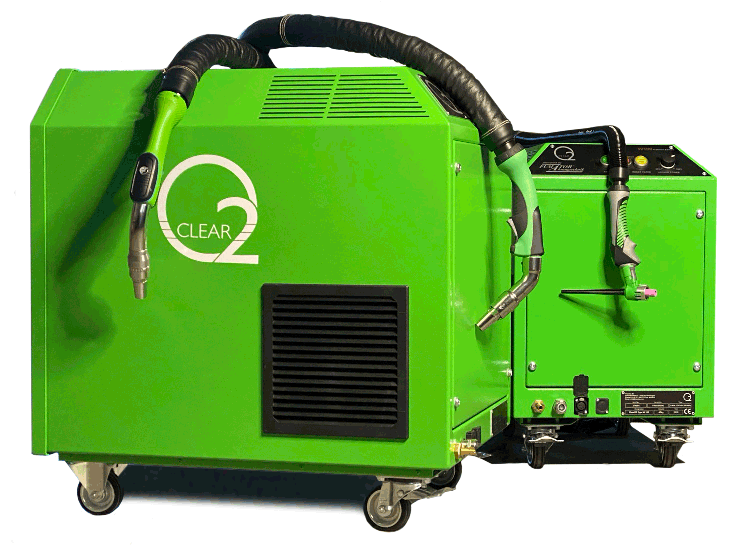

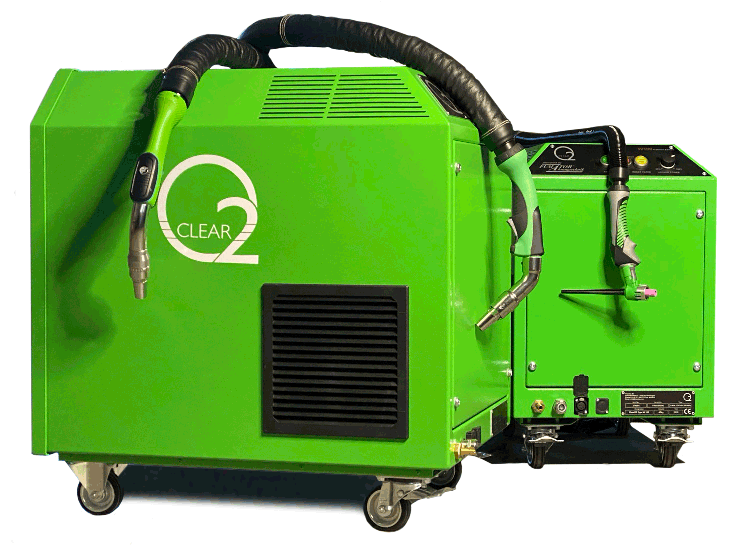

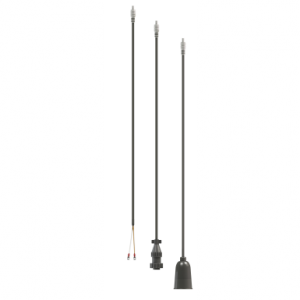

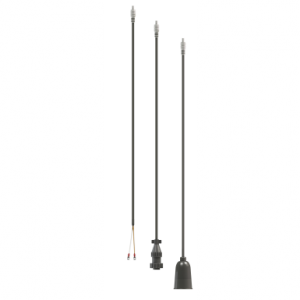

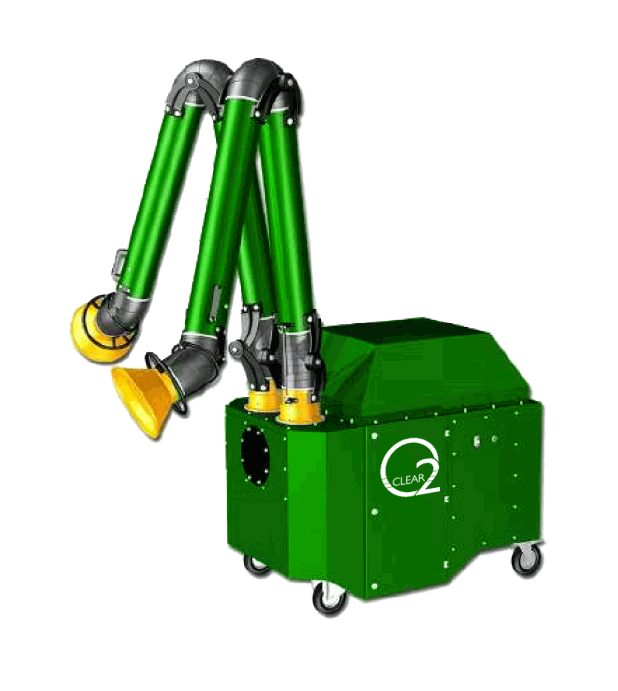

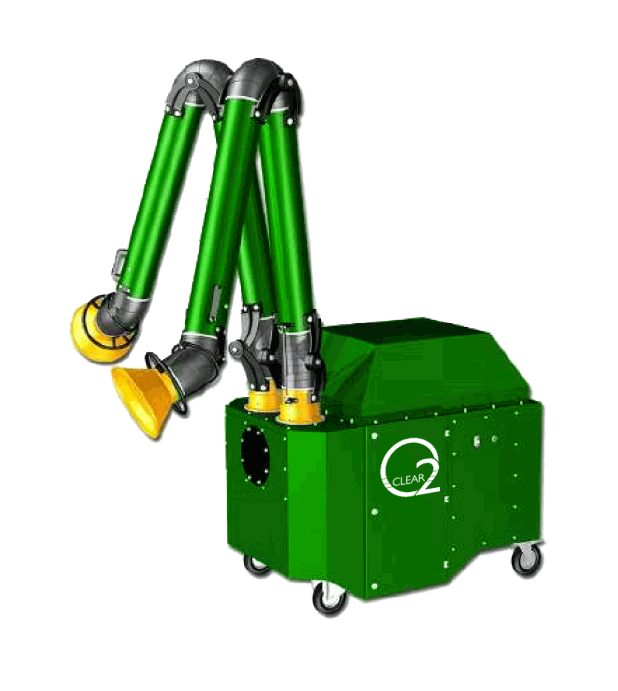

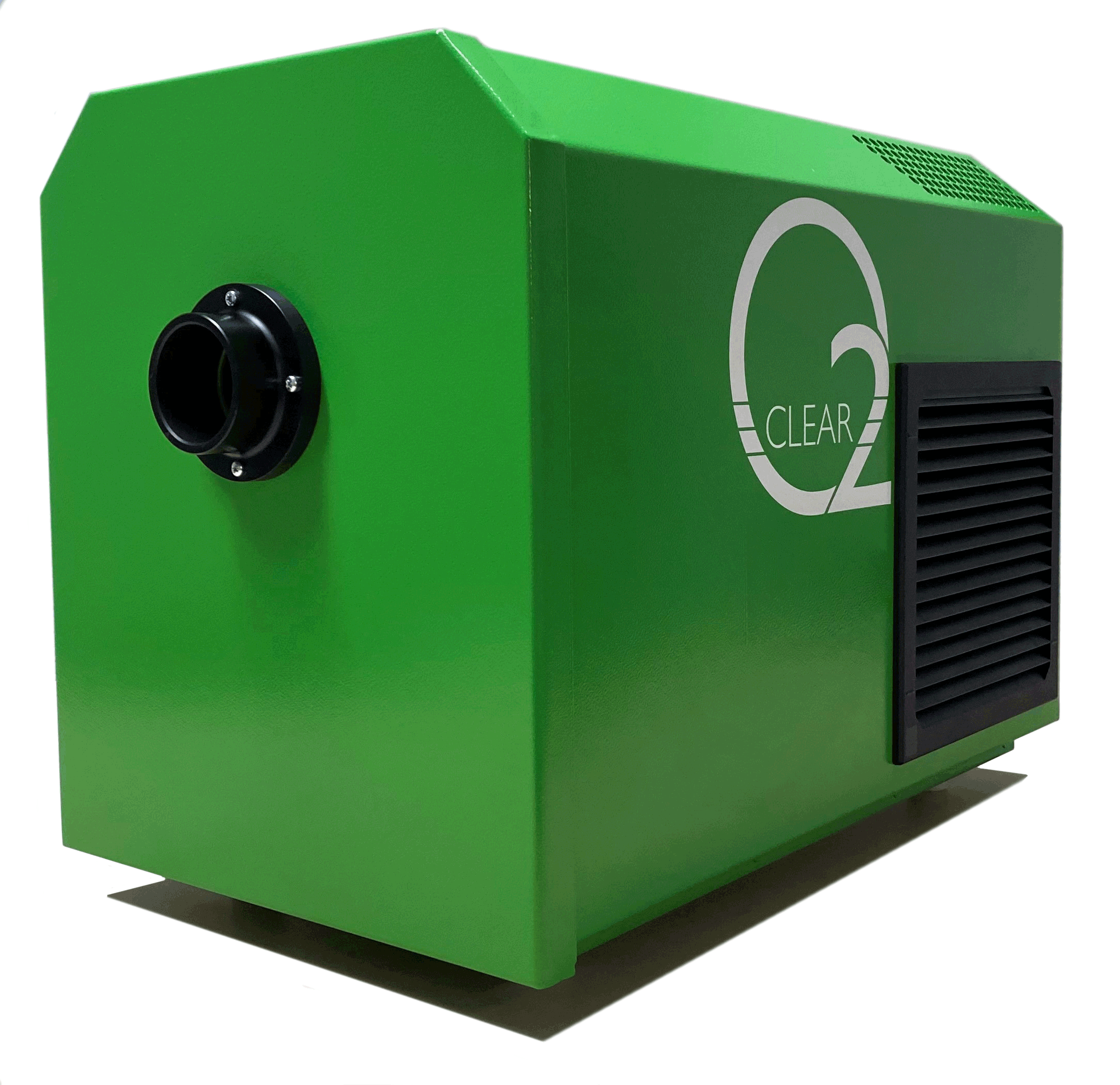

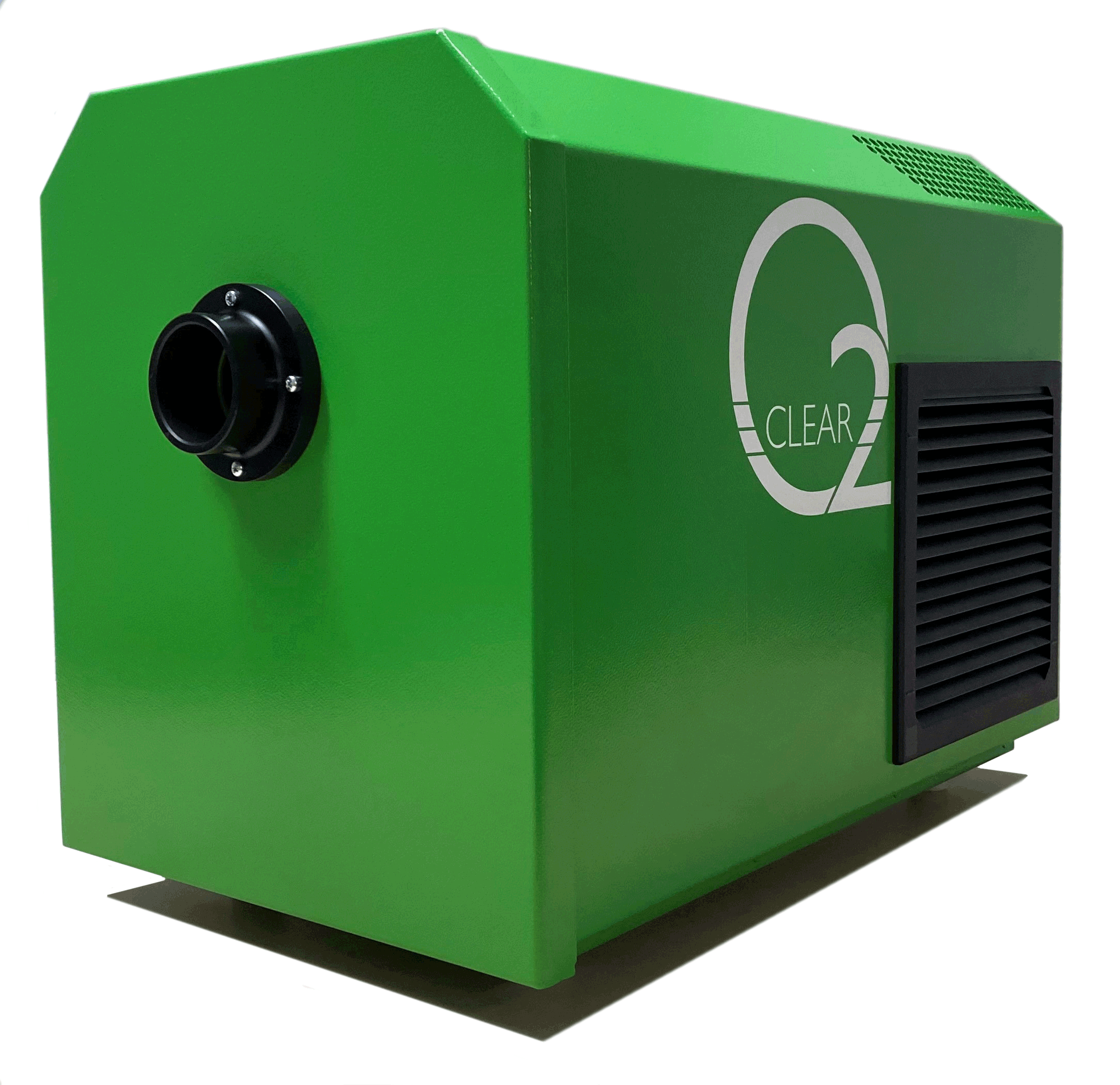

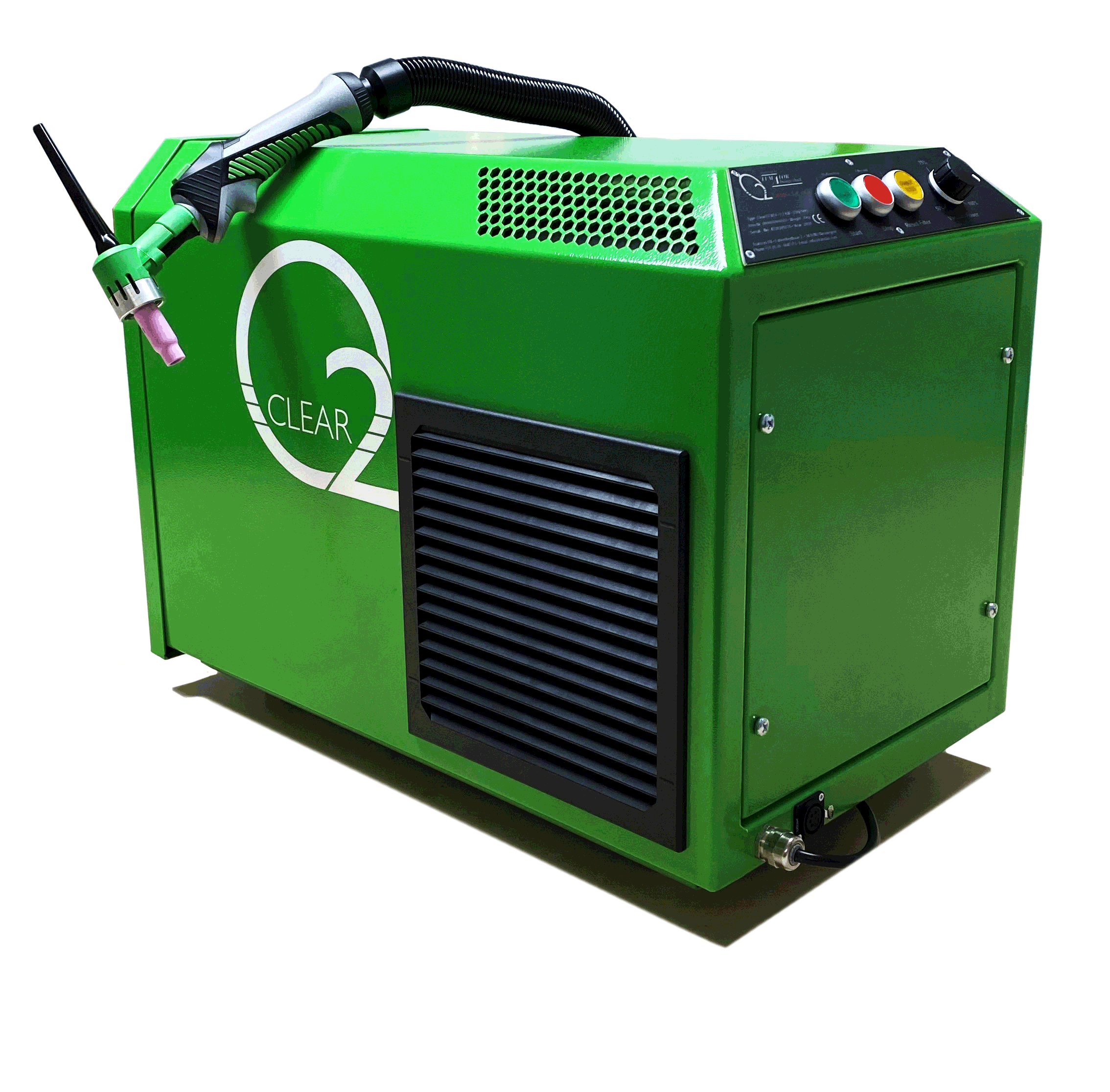

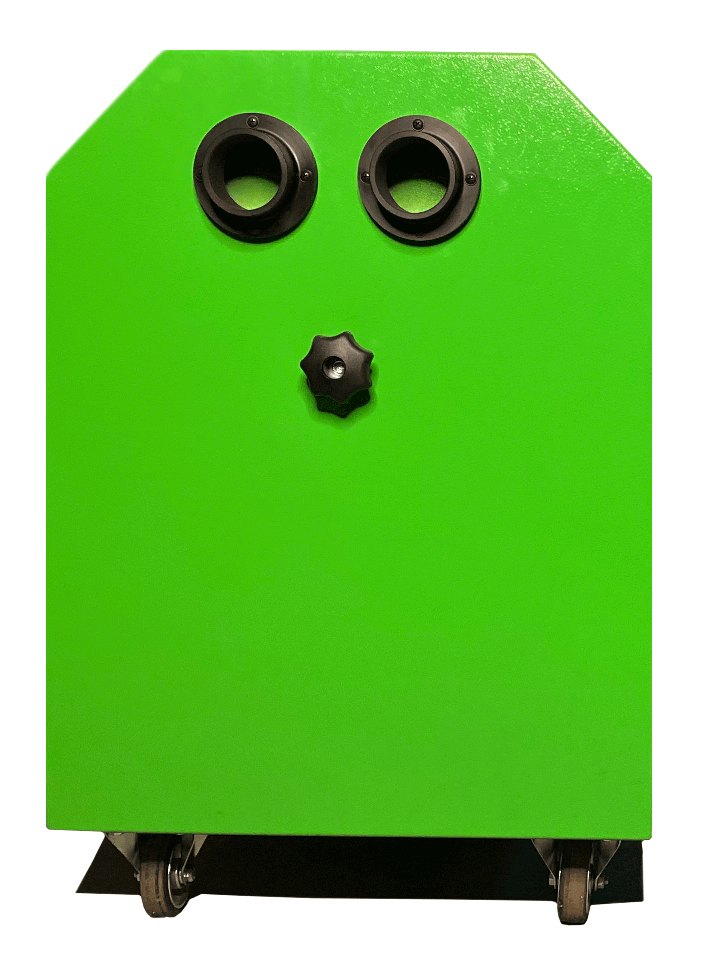

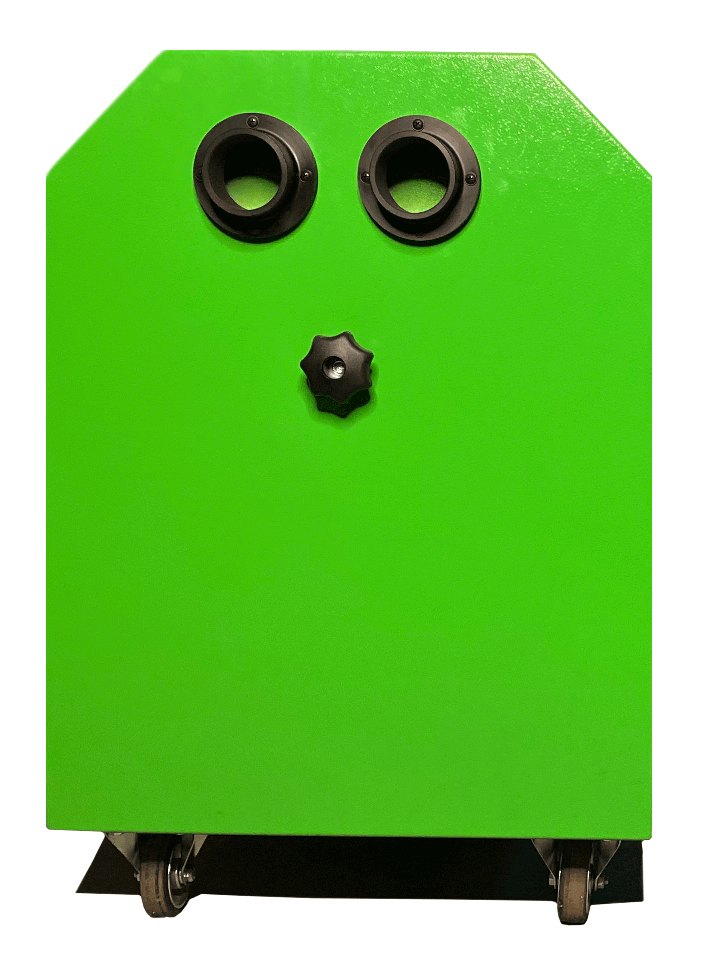

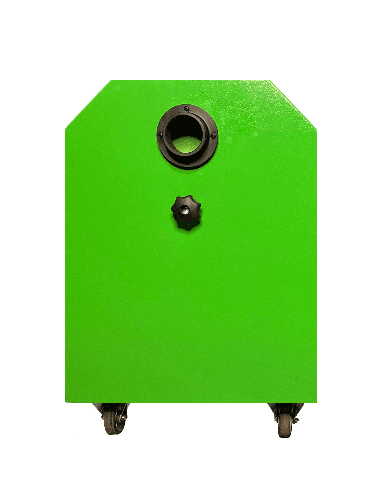

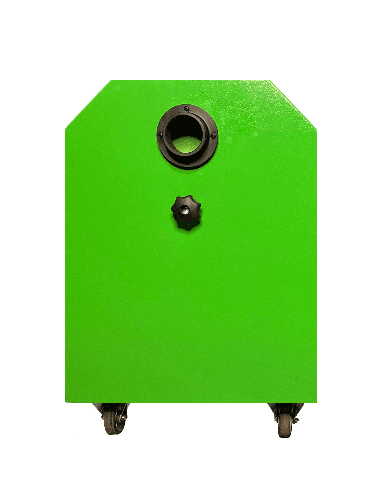

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

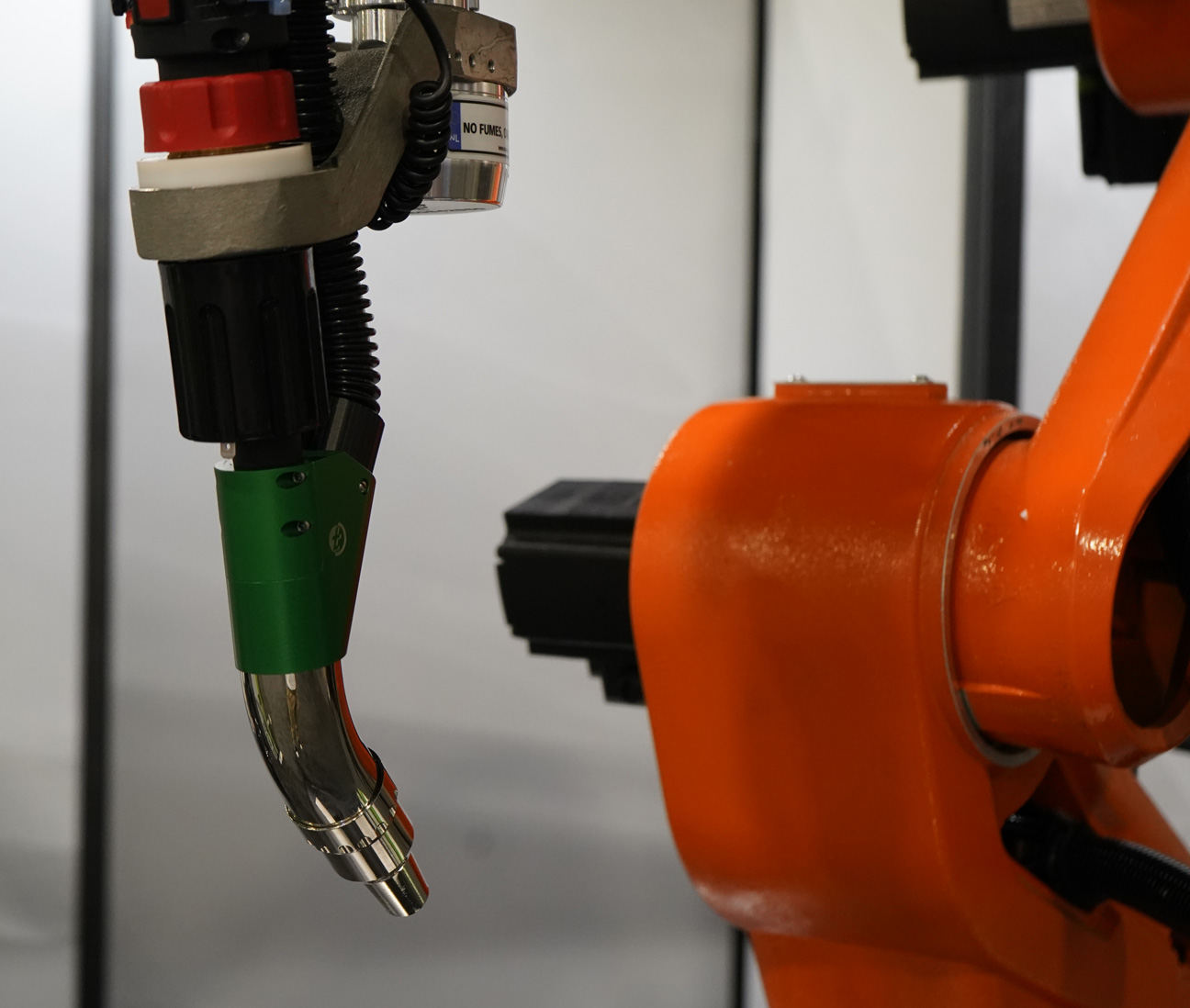

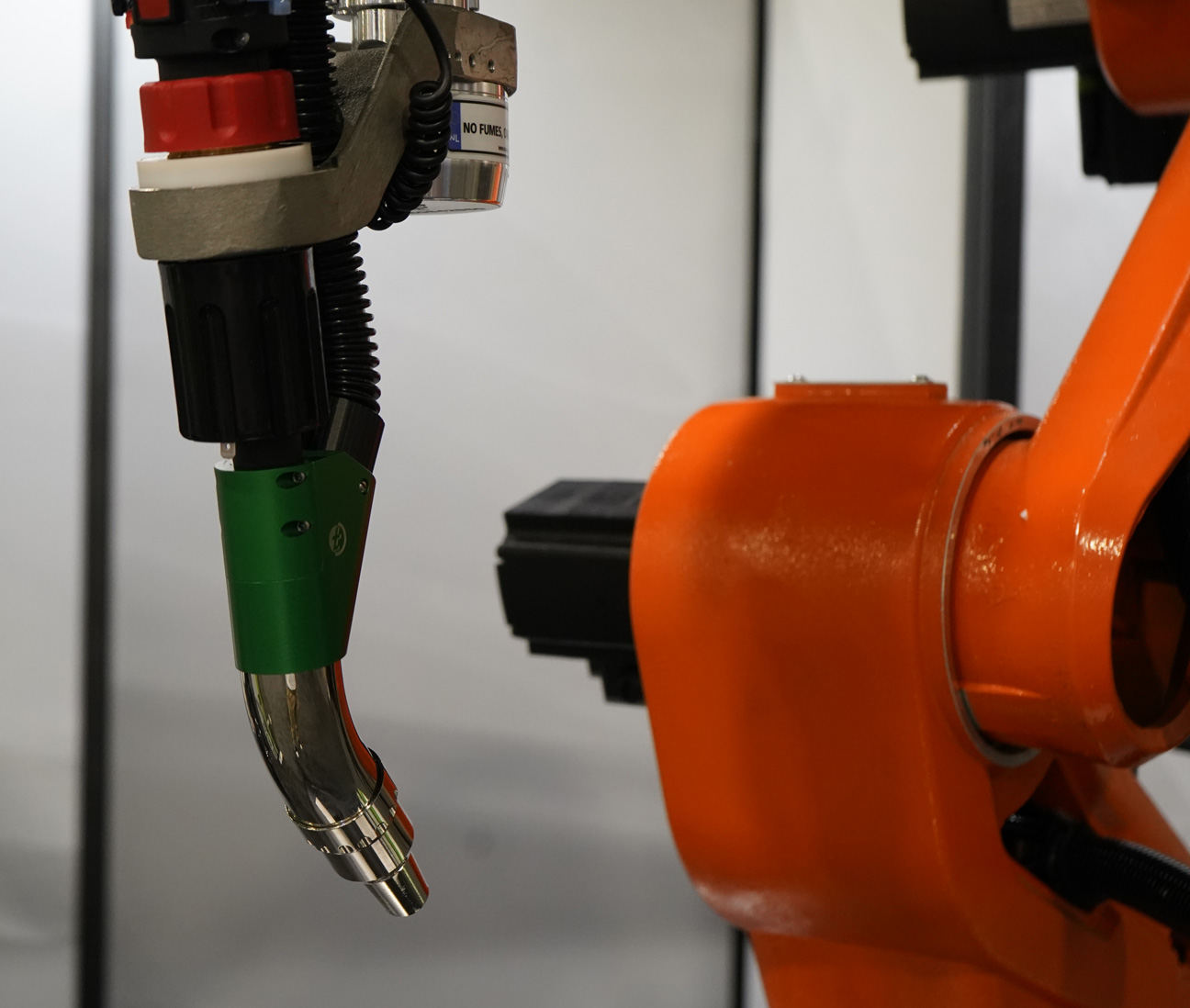

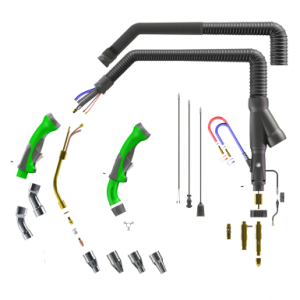

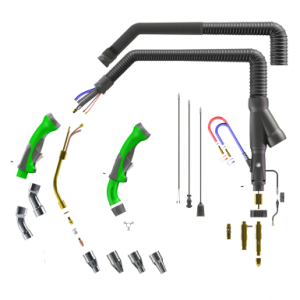

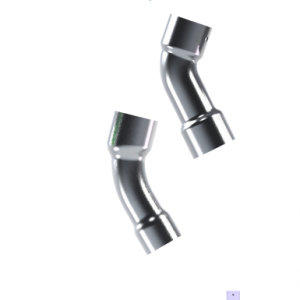

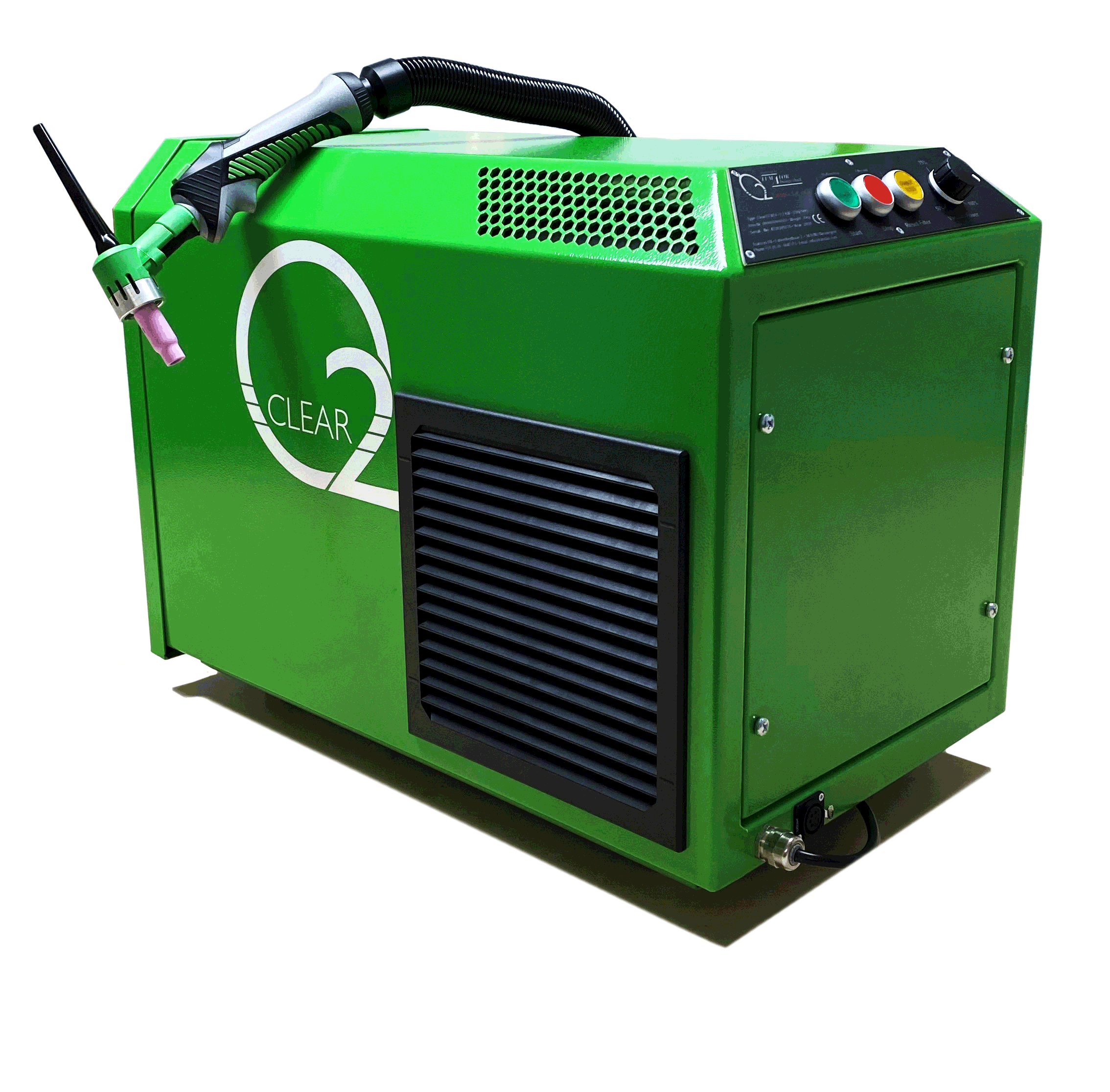

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

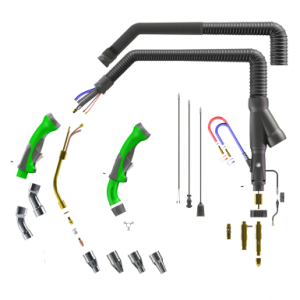

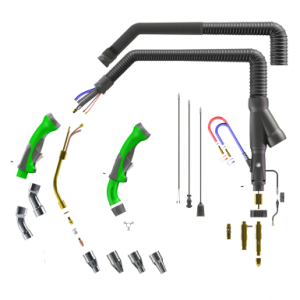

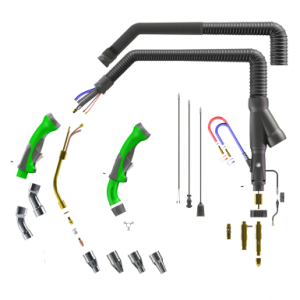

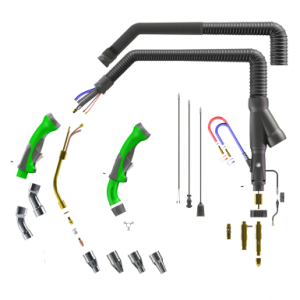

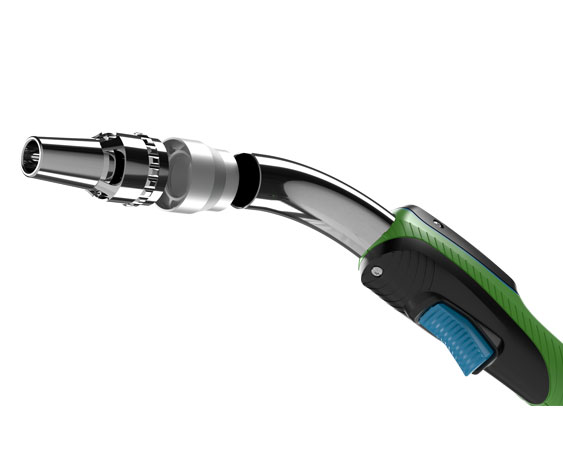

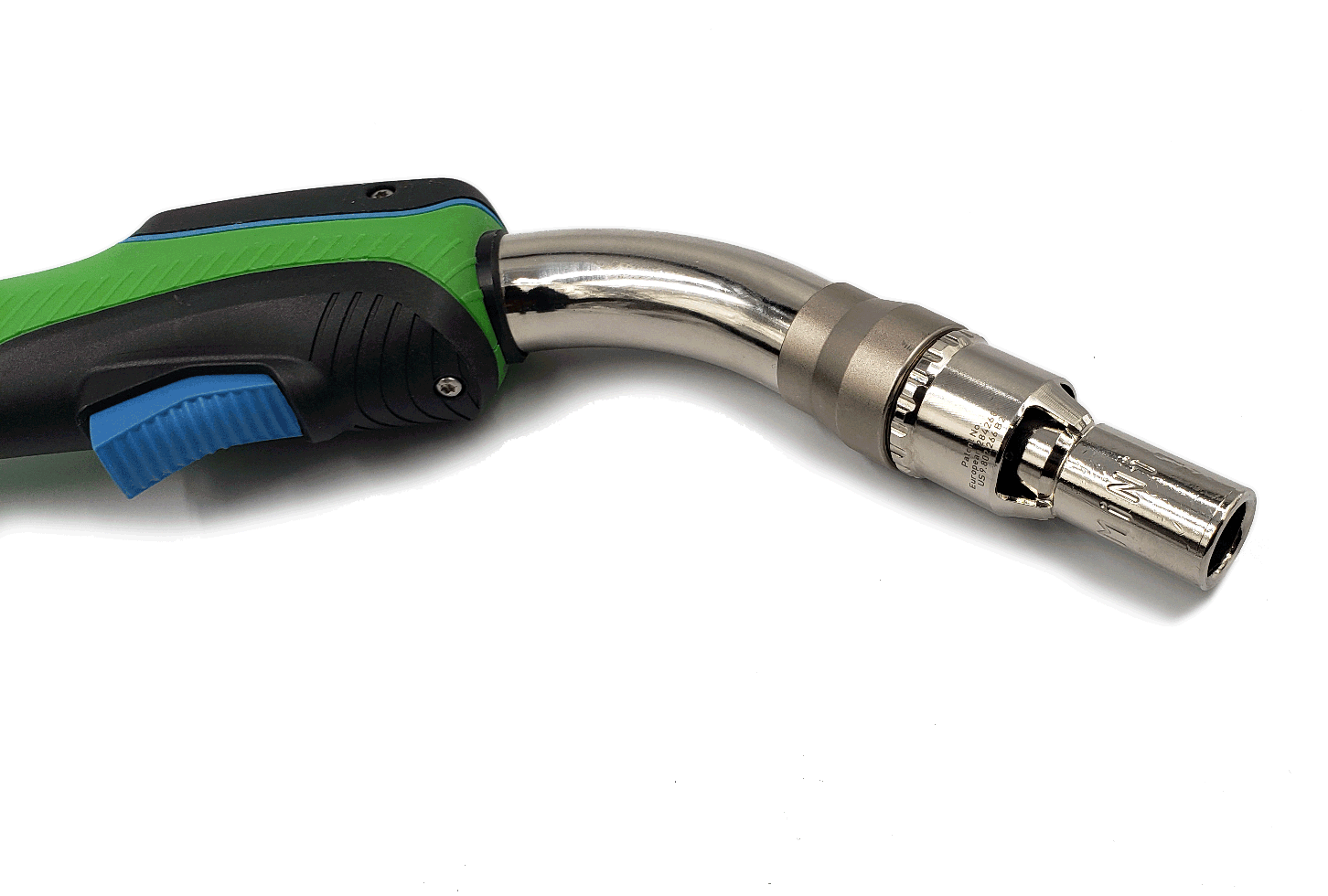

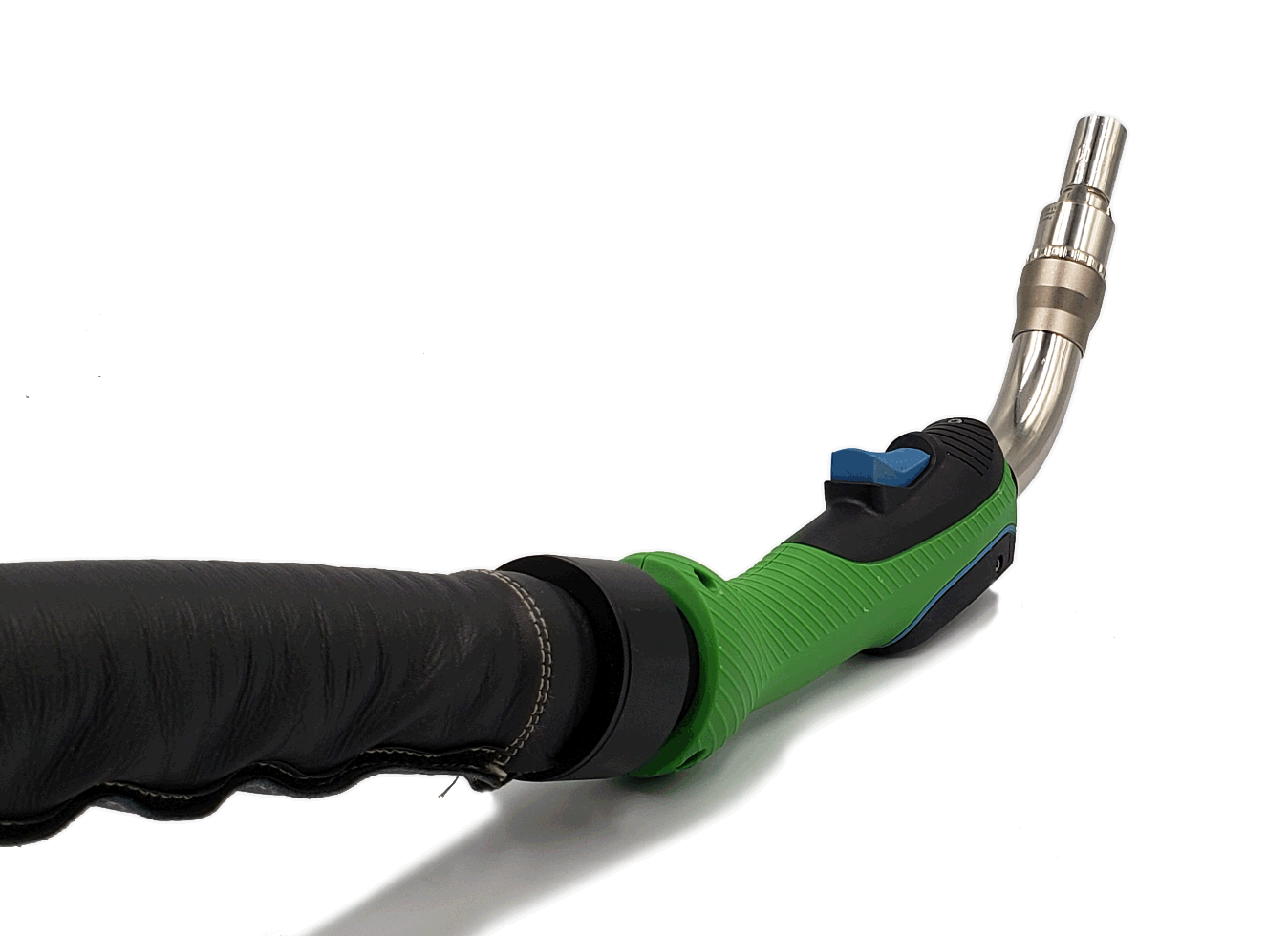

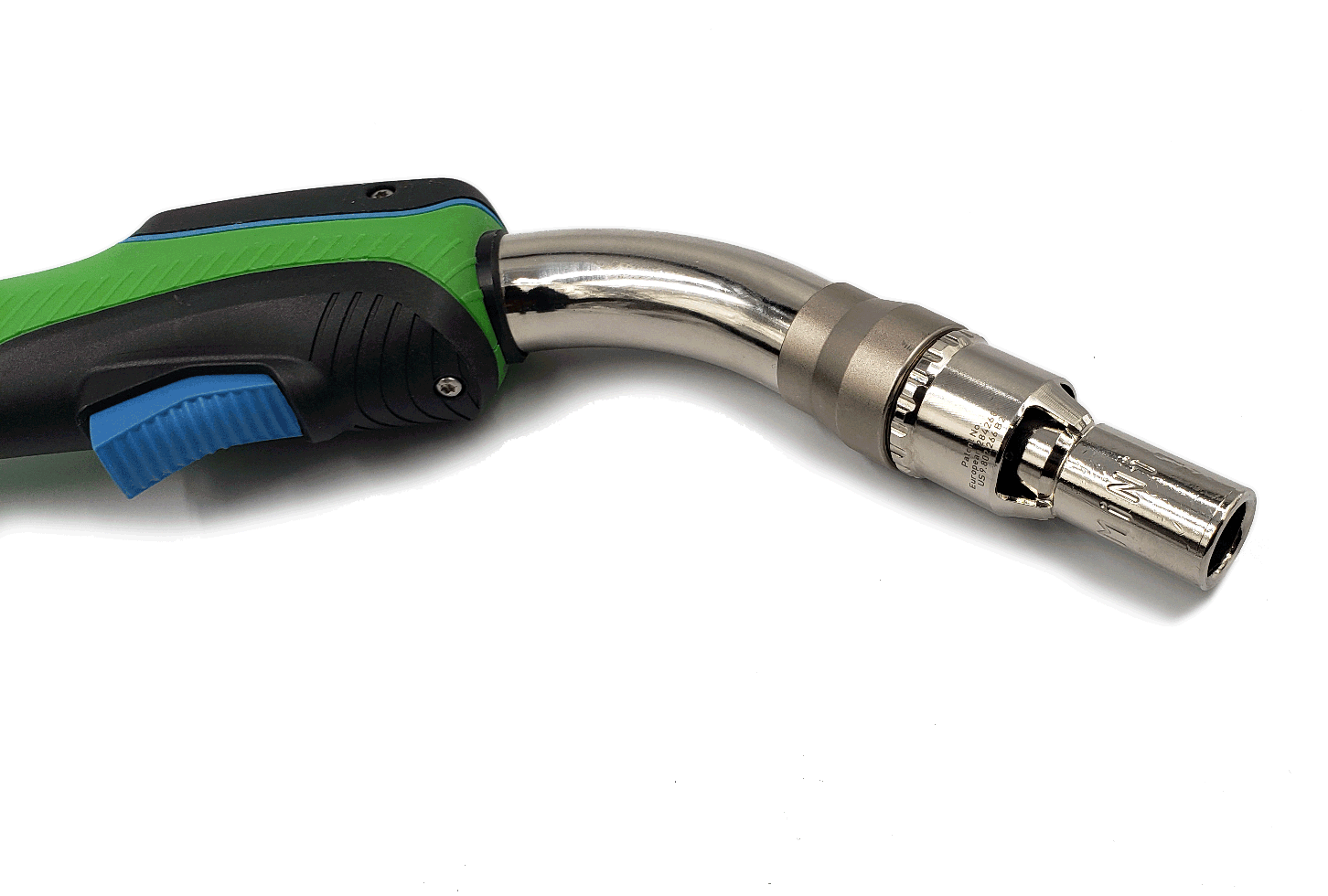

Welding torches and welding equipment from Translas are distinctive in ergonomics, durability, performance, shape, and appearance.

Translas Canada Industries Ltd.

Unit 5, 1099 Commerce Way

Woodstock, ON, N4V 0A2

Canada

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.

Welding fumes are a toxic mix of manganese, zinc oxide and chromium These can be dangerous if exposed to over longer term:

Antecedents such as asthma; or bronchitis.

Heavy Metal toxicity- Neurological effects

Higher cancer risk especially from hexavalent chromium fumes.

When you invest in fume extraction arm, and MIG welding guns with integrated extraction it is to protect your workers from long term health implications and reduce sick days, as well show that you are safety conscious.

2. Compliance with Workplace Safety Regulations

Occupational safety standards (OSHA and EU Directives) require that your employer retains the provision of a healthy workplace including de-creeping access to toxic fumes.

Non-compliance can lead to:

Severe punishment and lawsuits.

Shut down or halt operations.

Damage to your company’s name.

We meet regulatory requirements and better brand image as an employer when you use the right weld fume extractors.

3. Boosting Productivity with Clean Air

Workers who operate in dirty and polluted air usually look tired, sluggish or sick, actually bringing their individual productivity down. However, THEN high efficiency welding fume extractors are the answer:

Make it so workers can concentrate on the job, and not discomfort.

Limit health-related absences time on hold

Drive increased focus and staff morale in the workplace.

4. Enhancing Equipment Longevity

But welding fumes are not just bad for humans, the pollution can degrade machinery overtime. Metal debris and fume residues can fall on machinery, including:

Corrosion / wear

Blockages in ventilation / HVAC systems.

Decreased performance for delicate devices.

Applying either a portable fume extractor welder, or a fixed system will ensure your tools remain in tip-top condition which saves on repair and replacement.

5. Supporting Sustainability Goals

Environmental responsibility is now in industries everywhere. Weld fumes lead to air pollution which may harm not only your workforce but also the outside environment. These are some of the modern weld fume extraction systems based on advanced filters:

Prioritize the safety of what could end up being harmful aerosols escaping into the atmosphere.

Reduce your company’s carbon footprint.

Embed that your business is ethical compliant (and it can be a giant plus in the ‘eyes of prospective eco-conscientious clients).

Types of Fume Extraction Solutions

Portable Fume Extractors

Works well for grunt work or small scale jobs.

Compact, lightweight and portable.

Stationary systems for fume extraction

Great for large, dedicated welding areas in workshops of all sizes.

Built to last for the long run

Integrated Extraction Tools to accompany such advanced MIG and TIG welding guns

Directly capture fumes at source for optimal efficiency. limited

Choosing the Right Welding Fume Extractor for Your Needs

When choosing a fume extractor the following should be taken in, consideration

Size of the workspace: A larger workshop may want a fixed system, smaller will prefer the portability

Use intensity: The heavy-duty welding operations would need a system of higher power.

Filtration: Opt for HEPA filters or (preferable) activated carbon filters in your system.

Maintenance friendly: As the filter should change periodically and cleaning should not need downtime.

Maintenance Tips for Welding Fume Extractors

Here are some tips to maintain your system as efficient as possible

Weekly inspect filters and replace as appropriate.

Hire a Service to Clean and Remove Blockages From Ducts + Extraction arms.

Watch the airflow to make sure you are getting adequate exhaust.

Place the unit in a dry and ventilated place, to not rust or damage.

A Small Investment for a Big Impact

Though the purchase and upkeep of a welding fume extractor comes at a cost, the effects in the long term are more expensive not to use. Valuable for any welding operation, these systems provide worker safety and regulatory compliance as well as lengthy life of equipment.

Final Thoughts

Given the rapid evolution of industry in today’s coined landscape, safety and sustainability still takes center stage as well. Welding fume extractors are not just consumables, they are a dedication towards building a healthier, more productive working atmosphere.

Give your workplace the fume extraction system that it deserves and witness how this will overhaul everything related to your operations while safeguarding your team and ultimately elevating your company.

Ironically welding forms the foundation for many industries (Construction- manufacturing). Yet welding processes are key, but at a cost of workers’ health and safety as well as releasing known damaging fumes from the job. The time when you can get away with a bad welding fume extraction system is truly over. In this write-up, we are going to look into the key reasons why a fume extraction system is important for every workshop and how it can take your workplace to the next level.