Welding is a crucial part of many industries, from manufacturing to construction. However, it’s not without its risks, especially when it comes to weld fume exposure. The fumes produced during welding can be harmful to both welders and the environment. To protect your workforce and ensure compliance with safety regulations, choosing the right weld fume extraction machine is essential.

Before you start shopping for a weld fume extraction machine, it’s crucial to understand your specific needs. Different welding fume extractors processes produce varying levels and types of fumes. Consider the following factors:

Types of Welding Processes and Fume Generation: Whether you’re dealing with MIG, TIG, stick, or other types of welding, the fume generation can vary significantly. Understanding the unique characteristics of these processes is essential.

Specific Requirements for Your Workspace: Assess your workspace to determine where welding occurs, how often, and the specific tasks involved. Do you have welding stations in different areas, or is it a centralized welding operation?

Workplace Safety and Regulations: Familiarize yourself with local, national, and international safety regulations related to weld fume exposure. This knowledge will guide your decision-making process and help you stay compliant.

Weld fume extraction machines come in various types, each with its own advantages and limitations. Here are some common options to consider:

Portable vs. Stationary Extractors: Portable extractors are flexible and can be moved to different workstations. Stationary extractors are fixed in place and are suitable for dedicated welding stations.

Source-Capture vs. Ambient Systems: Source-capture systems capture fumes directly at the source, while ambient systems filter the air in the entire workspace. Your choice should depend on the nature of your welding tasks and the desired level of control.

Centralized vs. Decentralized Systems: Centralized systems connect multiple workstations to a single extraction unit, while decentralized systems have individual units for each workstation. Consider the layout of your workspace and the number of welding stations.

Choosing a weld fume extraction machine with the right capacity is critical. To determine the appropriate capacity, consider the following:

Calculating Necessary Airflow and Filtration Capacity: Calculate the volume of air you need to process per hour to effectively capture and remove fumes. This depends on factors such as the type of welding and the number of workstations.

Workspace Size and Layout: Ensure the machine’s capacity aligns with the size and layout of your workspace. Large, open areas may require more powerful extraction units.

Anticipating Future Growth and Changing Needs: Consider whether your operation is likely to expand in the future. Investing in a system that can adapt to changing needs is a wise choice.

The filtration technology used in your weld fume extraction machine plays a significant role in its effectiveness. Here are some filtration options to consider:

Different Filter Types: Common filter types include HEPA (High-Efficiency Particulate Air), activated carbon, and electrostatic filters. The choice should be based on the composition of the fumes in your workplace.

Choosing the Right Filtration Technology: Understanding the composition of welding fumes extractors is crucial for selecting the right filtration technology. Some fumes may require more specialized filtration to effectively remove harmful particles.

Maintenance Requirements for Filters: Consider the maintenance needs of the filtration system, such as the frequency of filter replacement and cleaning. This can affect long-term operating costs.

In addition to fume extraction, consider the impact of noise levels on your workplace. Noisy extraction machines can lead to discomfort and productivity issues. When choosing a machine:

Understanding the Impact of Noise: High noise levels in the workplace can lead to stress, reduced concentration, and even hearing damage. Select a machine with noise reduction features if noise is a concern.

Balancing Extraction Efficiency and Noise Levels: Striking a balance between efficient fume extraction and acceptable noise levels is crucial. Quiet machines with powerful extraction capabilities are available on the market.

Efficiency and operating costs are essential considerations when choosing a weld fume extraction machine. Factors to keep in mind include:

Evaluating Energy Consumption: Look for machines that are energy-efficient. Lower energy consumption not only saves money but also reduces your environmental footprint.

Lifespan of Consumables: Consider the lifespan of consumable parts, such as filters. Longer-lasting consumables can reduce maintenance costs and downtime.

Calculating Long-Term Operating Costs: While the upfront cost of a machine is important, don’t forget to calculate the long-term operating costs, including energy, consumables, and maintenance.

It’s essential to choose a weld fume extraction machine that is compatible with your existing welding equipment and can be seamlessly integrated into your workflow. Consider the following:

Compatibility with Existing Welding Equipment: Ensure that the extraction machine can be easily connected to your welding fume extractors equipment, such as welding torches and workbenches.

IoT Integration and Remote Monitoring: Some modern extraction systems offer IoT integration, allowing you to monitor and control the system remotely. This can be a valuable feature for efficiency and maintenance.

Ease of Installation and System Scalability: Choose a machine that is easy to install and can be scaled up or down to accommodate changes in your welding operation.

Staying compliant with safety standards and regulations is non-negotiable when it comes to weld fume extraction. Here’s what you need to know:

Familiarize with Safety Regulations: Stay informed about local, national, and international safety regulations related to weld fume exposure. Ignorance is not an excuse, and non-compliance can lead to serious consequences.

Ensure the Machine Complies: When choosing a weld fume extraction machine, ensure that it complies with all relevant safety standards. Look for certifications and testing to confirm compliance.

The Role of Certification and Testing: Some extraction machines come with third-party certifications, which can provide extra assurance of their safety and effectiveness.

Proper maintenance is essential to keep your weld fume extraction machine running smoothly and effectively. Consider the following maintenance-related factors:

The Importance of Regular Maintenance: Regular maintenance is key to ensuring the longevity and efficiency of your extraction system. Neglecting maintenance can result in reduced performance and increased costs.

Availability of Spare Parts and Service Support: Check if spare parts for your machine are readily available. Ensure that the manufacturer or supplier offers reliable service support for repairs and maintenance.

Warranty and After-Sales Services: Consider machines that come with warranties and comprehensive after-sales services. This can provide peace of mind and financial protection.

Choosing the right weld fume extraction machine is not just a matter of safety; it’s an investment in the well-being of your workforce and the efficiency of your operation. It’s a decision that should not be taken lightly. Prioritize workplace safety and air quality by selecting a machine that aligns with your unique requirements.

For more information and to explore a range of weld fume extraction machines, you can visit Translas’ Fume Extraction Systems. Their solutions are designed to meet the highest standards of safety and performance, ensuring that your welding environment remains clean and safe.

Welding torches and welding equipment from Translas are distinctive in ergonomics, durability, performance, shape, and appearance.

Translas Canada Industries Ltd.

Unit 1-2, 1249 Seagrave Rd, Woodstock, ON N4T 0A8, Canada

Flip up welding goggles

Specifications

HC Anti-scratch

AF Anti-fog

W5 Shade 5

Safety grinding goggles

Specifications

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Indoor/Outdoor lens

Yellow

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Goggles

Clear

Specifications

Clear lens

HC Anti-scratch

AF Anti-fog

T230

Specifications

Sizes 8-11

T240

Specifications

Sizes 7-11

T268

Specifications

Sizes 8,10,11

T269

Specifications

Sizes 8-11

T275

Specifications

Sizes 8-12

T480

Specifications

Sizes 8,10

T580

Specifications

Sizes 6-11

T88

Specifications

Sizes 8-11

Extended hood and leather coverage

Specifications

Extended Hood for Welding Helmet

Extended hood made out of durable flame-retardant cotton. It is suitable for overhead welding and helps on-site and field welders be protected against burns caused be welding spatter.

Can be ordered together or separately

Characteristics:

Force 300 Automatic welding helmet

Specifications

Force 300

Force 700 Automatic welding helmet

Specifications

Force 710S

Force 730S

Force 800 Automatic welding helmet

Specifications

Force 820S:

Force 830S:

Force 900 Automatic Welding Helmet

With flip-up lens

Suitable for welding, grinding and cutting

Specifications Force 900 Welding Helmet

The automatic Force 900 welding helmet has the welder covered in every situation – welding, grinding and cutting.

ClearView

Cartridge is equipped with ClearView Technology, which provides you with an ultra-clear view during welding.

Digital Display Control

The Force 900 Digital Display Control has a clear interface design. You can switch between different modes within seconds. It also has a memory function which allows you to save the set parameters when switching between modes.

Multi-Functional Flip-UP Design

The Force 900 is a flip-up helmet with easy lift for grinding function, suiting welding/cutting/grinding mode. The transparent grinding lens is curved with a large view area of (20 x 12 cm). The welding lens with the highest optical glass -1/1/1/1- provides an exceptionally clear view of the arc during welding.

Technical Specifications Helmet

20 °C ~ +70 °C (-4 °F ~ 158 °F)

PAPR Fresh air system

Specifications

Inhaled air 50 times cleaner than air in the immediate area

TH2 approved

Comfortable to wear

Unique design

Suitable for grinding and cutting

Easy to clean head cap

AirForce Fresh air set with flip-up helmet

Specifications

P.N.: 570400

This product could be used in below field:

1- Isolating ward and medical observation site

2-Transfer of the infected

3-Corpse treatment

4-Environment disinfection

5-Sample collection

6-Laboratory testing

Ultrasonic seaming technology

Seamed with ultrasonic welding, with high-intensity feature and longer lifetime.

Multi-layer fabric

Lightweight specialized fabric. TM-H2 with a longer length to protect neck and shoulder.

Full view visual field

Large window size, curved design to better fit face-line, expanding the visual field.

Adjustable headgear

Adjustable headgear, with soft sweatband, improving the wearing comfort.

Leather apron

90 x 70 cm

Specifications

Leather apron

90 x 70 cm

Leather arm protectors (pair)

Specifications

Leather arm protectors (pair)

Leather jacket

Sizes L, XL

Specifications

Leather jacket

Sizes L, XL

Leather leg proctectors (pair)

Specifications

Leather leg proctectors (pair)

Leather pants

Size L

Specifications

Leather pants (without belt)

Size L

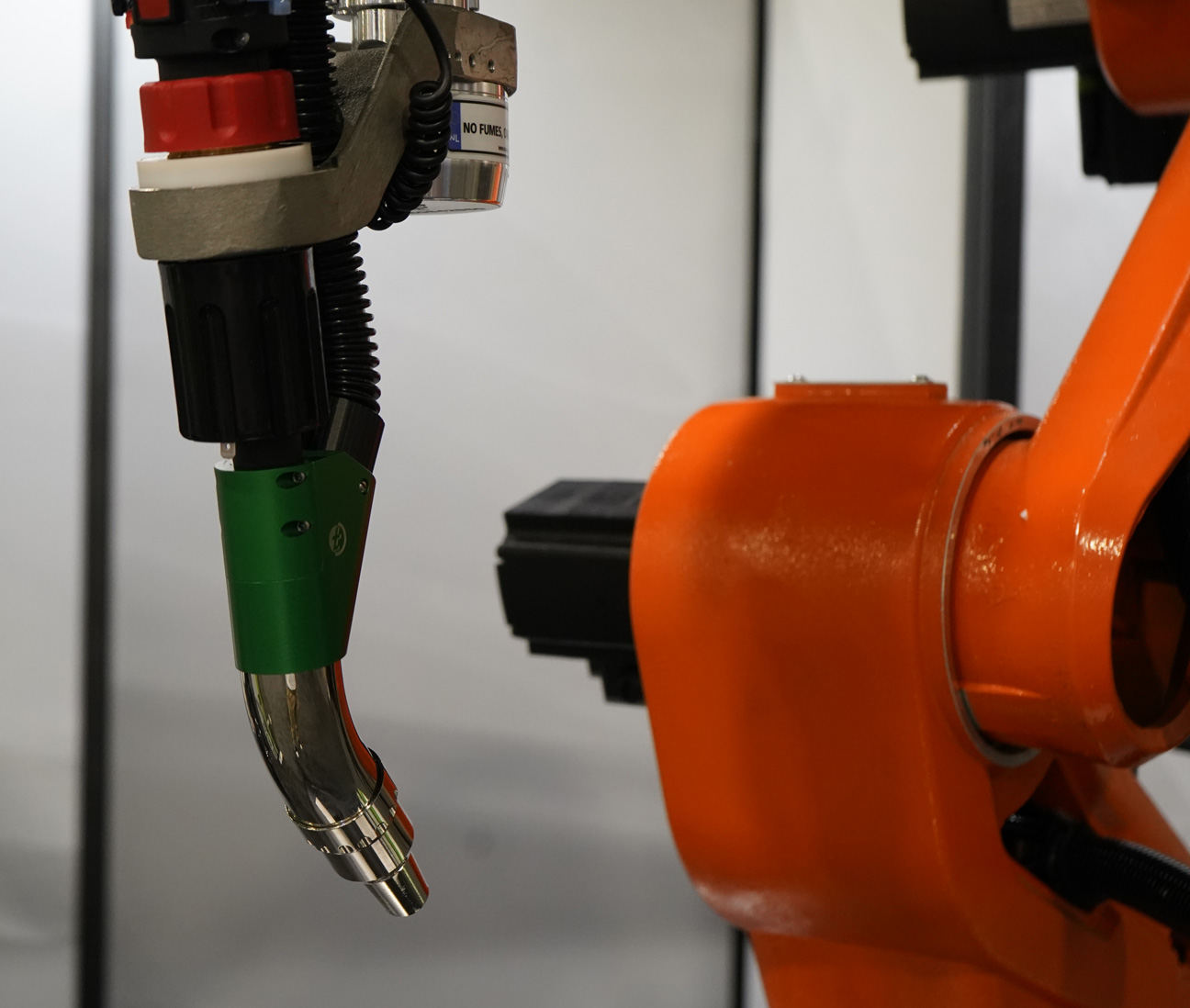

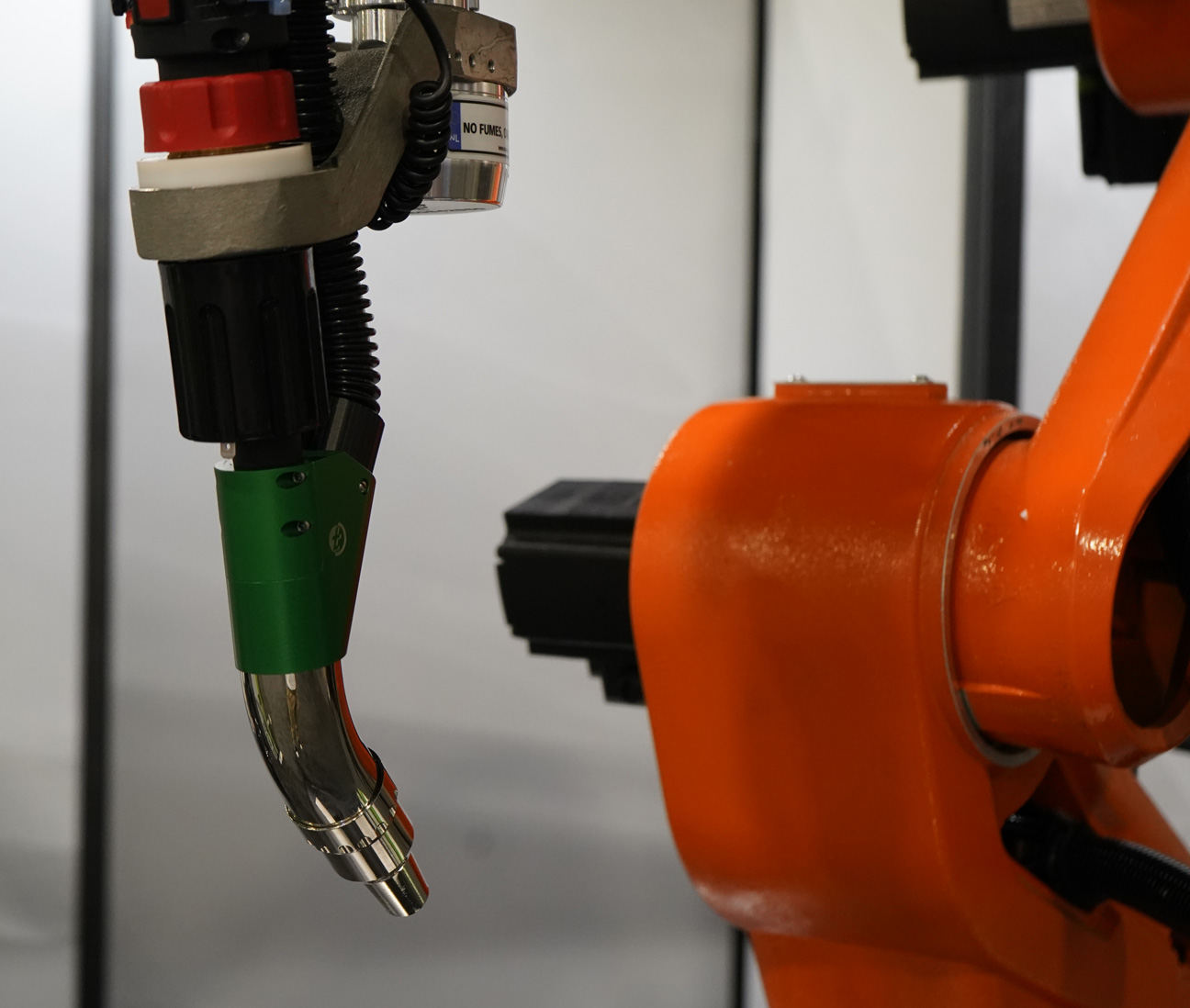

10XR Robotic 500 MIG Fume Extraction Gun – Water COOLED

MIXED GASES – 500 AMP, DUTY CYCLE – 100%

With the 10XR Robotic MIG Extraction Gun, harmful welding fumes can be safely and effectively extracted right at the source directly through the gun.

When the 10XR Robotic Welding Fumes Extractor is used with the ClearO2 W-Series 100 and 200, it allows for up to 98% of welding fume removal, which forms during the welding process. The fumes are extracted directly from the point of origin, through the nozzle before entering the atmosphere.

In addition to cleaner air, your employees will be able to work in a more pleasant environment.

By using the 10XR Robotic Welding Fumes Extractor, you have significantly less investment in alternative extraction options as it eliminates the requirement of a hood, curtain and larger powerful extraction systems being installed.

Experience significant savings with the 10XR with lower initial investment costs, lower operating costs and minimized maintenance costs including cleaning and filter life. Experience energy efficiencies compared to the current Industrial robot solutions that are available today.

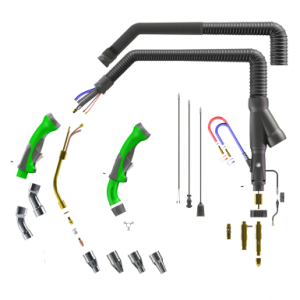

8XC Cobot 400 MIG Fume Extraction – AIR COOLED

CO2 – 420 AMP, MIXED GASES – 400 AMP, DUTY CYCLE – 100%

The 8XC Cobot Fume Extractor reduces welding fume Up To 98% and has a unique contact tip for manual fitting and durability. Moreover, This cobot fume extractor gun designs a special contact tip for a longer lifetime. Also, we created two unique nozzles, 14mm and 17mm, for optimal performance and durability.

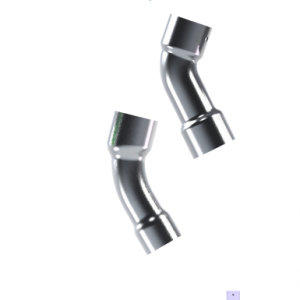

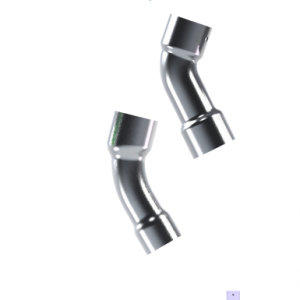

It is designed to be one of the most efficient fume extraction systems available in the welding industry. This torch is available at four different angles: 22°, 35°, 45°, and straight. When the 8XC Cobot MIG Fume Extractor is used with the ClearO2 W-series 100 and 200, it allows for up to 98% of welding fumes to be captured directly at the fume source. As a result, this Cobot 8XC MIG Fume Extractor is one of the safest and most effective welding fume extraction solutions available to ensure the safety of welding workers and for better working environments and working with the UR10e, UR5e, & UR16e Universal Robots.

HOW DOES IT WORK?

The 8XC MIG Fume Extractor is specifically designed for use by Cobots and Semi-Automated machines. There is a special design of nozzle on the 8XR and the combination of the unique design with the ClearO2 W-series, 100 and 200, provides the most effective results in the direct extraction of fumes from the source. In addition, the nickel-plated contact tips are designed to last a longer time than the other contact tips on the market. These tips are available for use with all kinds of wires and in different sizes. The 8X MIG Cobot fume extractor can use three types of Universal Robots: UR5e, UR10e, and UR16e.

To achieve the most outstanding results possible, the nozzle is unique in design. The openings, wall thickness, and size are all special to the nozzle. In addition, we have developed the grip ribs so that they perform optimally for optimal operation and superior performance.

8XC Cobot 500 MIG Fume Extraction Gun – Water COOLED

CO2 – 550 AMP, MIXED GASES – 500 AMP, DUTY CYCLE – 100%

The 8XC Cobot MIG Fume Extractor reduces welding fume Up To 98% and has a unique contact tip for manual fitting and durability. Moreover, This cobot fume extractor gun designs a special contact tip for a longer lifetime. Also, we created two unique nozzles, 14mm and 17mm, for optimal performance and durability.

It is designed to be one of the most efficient fume extraction systems available in the welding industry. This torch is available in four different angles: 22°, 35°, 45°, and straight. When the 8XC Cobot MIG Fume Extractor is used with the ClearO2 W-series 100 and 200, it allows for up to 98% of welding fumes to be captured directly at the fume source. As a result, this Cobot 8XC MIG Fume Extractor is one of the safest and most effective welding fume extraction solutions available to ensure the safety of welding workers and for better working environments and working with the UR10e, UR5e, & UR16e Universal Robots.

HOW DOES IT WORK?

The 8XC MIG Fume Extractor is specifically designed for use by Cobots and Semi-Automated machines. There is a special design of nozzle on the 8XC and the combination of the unique design with the ClearO2 W-series, 100 and 200, provides the most effective results in the direct extraction of fumes from the source. In addition, the nickel-plated contact tips are designed to last a longer time than the other contact tips on the market. These tips are available for use with all kinds of wires and in different sizes. The 8XC MIG Cobot fume extractor can use three types of Universal Robots: UR5e, UR10e, and UR16e.

To achieve the most outstanding results possible, the nozzle is unique in design. The openings, wall thickness, and size are all special to the nozzle. In addition, we have developed the grip ribs so that they perform optimally for optimal operation and superior performance.

8XC Cobot 500 MIG Fume Extraction Gun – Water COOLED

CO2 – 550 AMP, MIXED GASES – 500 AMP, DUTY CYCLE – 100%

The 8XC Cobot Fume Extractor reduces welding fume Up To 98% and has a unique contact tip for manual fitting and durability. Moreover, This cobot fume extractor gun designs a special contact tip for a longer lifetime. Also, we created two unique nozzles, 14mm and 17mm, for optimal performance and durability.

It is designed to be one of the most efficient fume extraction systems available in the welding industry. This torch is available in four different angles: 22°, 35°, 45°, and straight. When the 8XC Cobot MIG Fume Extractor is used with the ClearO2 W-series 100 and 200, it allows for up to 98% of welding fumes to be captured directly at the fume source. As a result, this Cobot 8XC MIG Fume Extractor is one of the safest and most effective welding fume extraction solutions available to ensure the safety of welding workers and for better working environments and working with the UR10e, UR5e, & UR16e Universal Robots.

HOW DOES IT WORK?

The 8XC MIG Fume Extractor is specifically designed for use by Cobots and Semi-Automated machines. There is a special design of nozzle on the 8XC and the combination of the unique design with the ClearO2 W-series, 100 and 200, provides the most effective results in the direct extraction of fumes from the source. In addition, the nickel-plated contact tips are designed to last a longer time than the other contact tips on the market. These tips are available for use with all kinds of wires and in different sizes. The 8XC MIG Cobot fume extractor can use three types of Universal Robots: UR5e, UR10e, and UR16e.

To achieve the most outstanding results possible, the nozzle is unique in design. The openings, wall thickness, and size are all special to the nozzle. In addition, we have developed the grip ribs so that they perform optimally for optimal operation and superior performance.

8XC MINI Cobot 250 MIG Fume Extraction Gun – AIR COOLED

CO2 – 280 AMP, MIXED GASES – 250 AMP, DUTY CYCLE – 100%

The 8XC Cobot Fume Extractor reduces welding fume up to 98% and has a unique contact tip for manual fitting and durability. Moreover, this fume extraction welding gun Canada designs a special contact tip for a longer lifetime. Also, we created two unique nozzles, 14mm and 17mm, for optimal performance and durability, ideal for use with fume extraction welding guns Canada.

It is designed to be one of the most efficient fume extraction systems available in the welding industry. This torch is available in four different angles: 22°, 35°, 45°, and straight. When the 8XC Cobot MIG Fume Extractor is used with the ClearO2 W-series 100 and 200, it allows for up to 98% of welding fumes to be captured directly at the fume source, making it an excellent choice for fume extraction welding guns Canada. As a result, this Cobot 8XC MIG Fume Extractor is one of the safest and most effective welding fume extraction solutions available to ensure the safety of welding workers and for better working environments and working with the UR10e, UR5e, & UR16e Universal Robots.

HOW DOES IT WORK?

The 8XC MIG Fume Extractor is specifically designed for use by Cobots and Semi-Automated machines. There is a special design of nozzle on the 8XR and the combination of the unique design with the ClearO2 W-series, 100 and 200, provides the most effective results in the direct extraction of fumes from the source. In addition, the nickel-plated contact tips are designed to last a longer time than the other contact tips on the market. These tips are available for use with all kinds of wires and in different sizes. The 8XC MIG Cobot fume extractor can use three types of Universal Robots: UR5e, UR10e, and UR16e, making it a top choice for fume extraction welding guns Canada.

To achieve the most outstanding results possible, the nozzle is unique in design. The openings, wall thickness, and size are all special to the nozzle. In addition, we have developed the grip ribs so that they perform optimally for optimal operation and superior performance, especially when paired with fume extraction welding guns Canada.

Air flow meter Extractor

Gas flow meter Extractor

Brush

Multitool

Ceramic spray

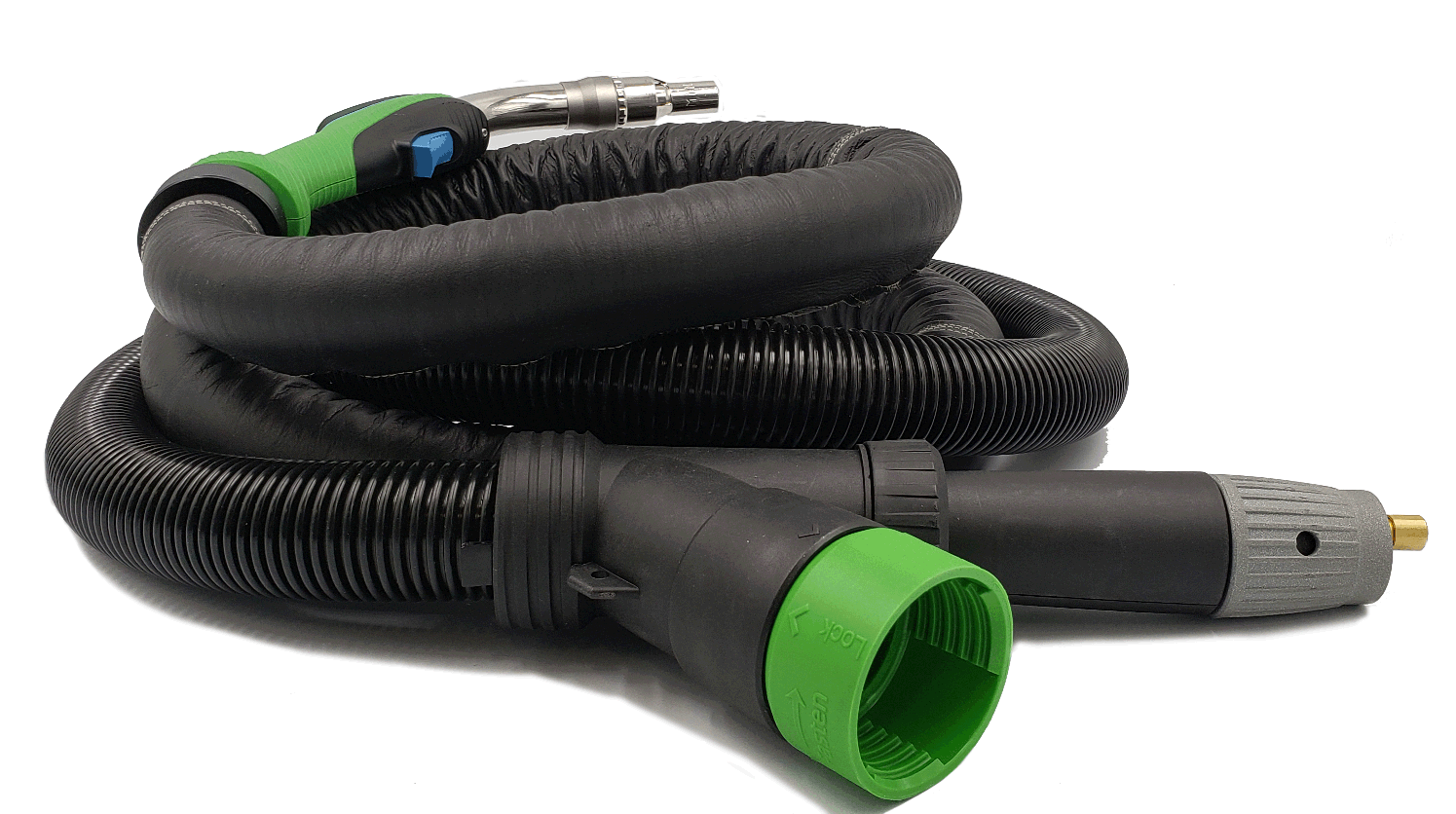

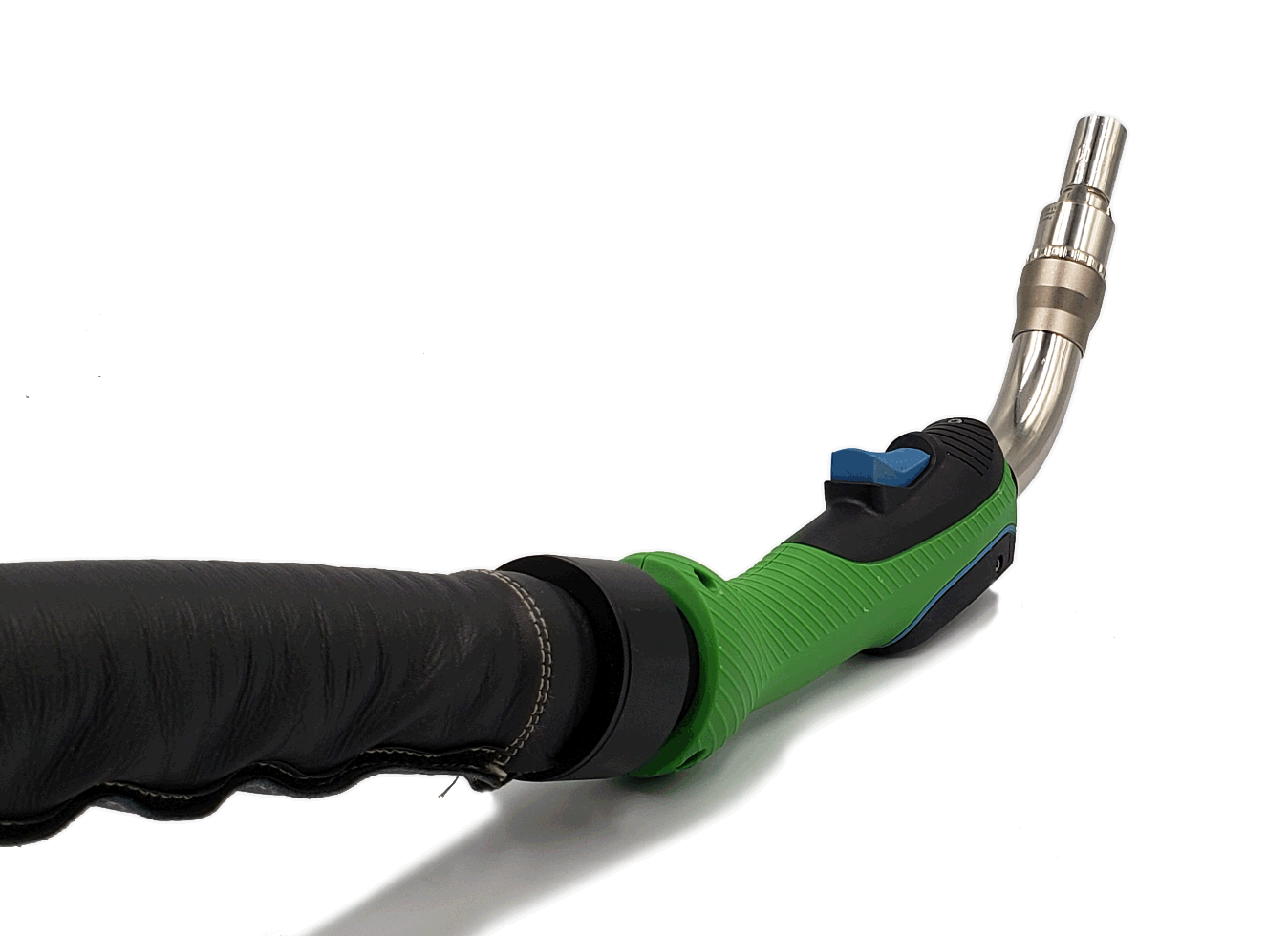

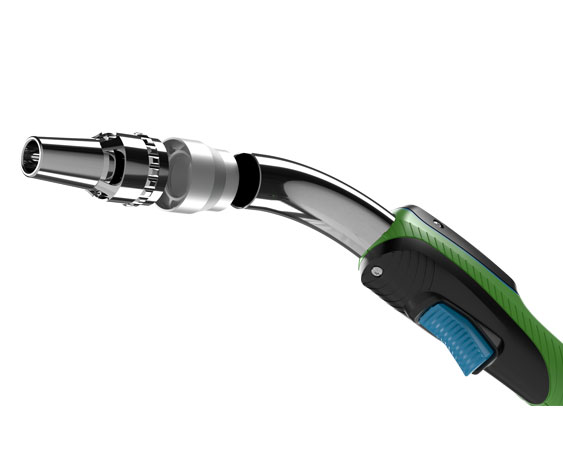

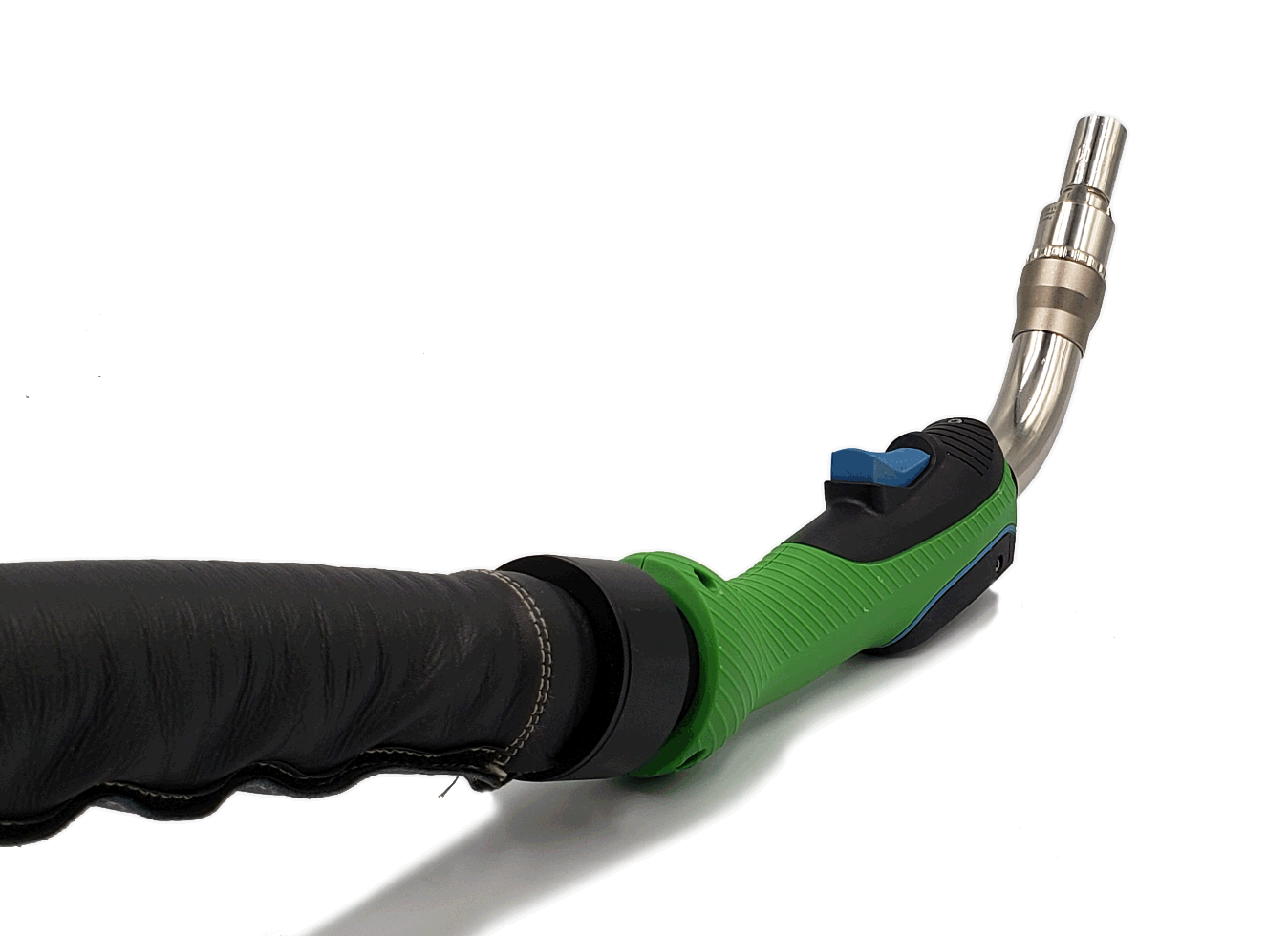

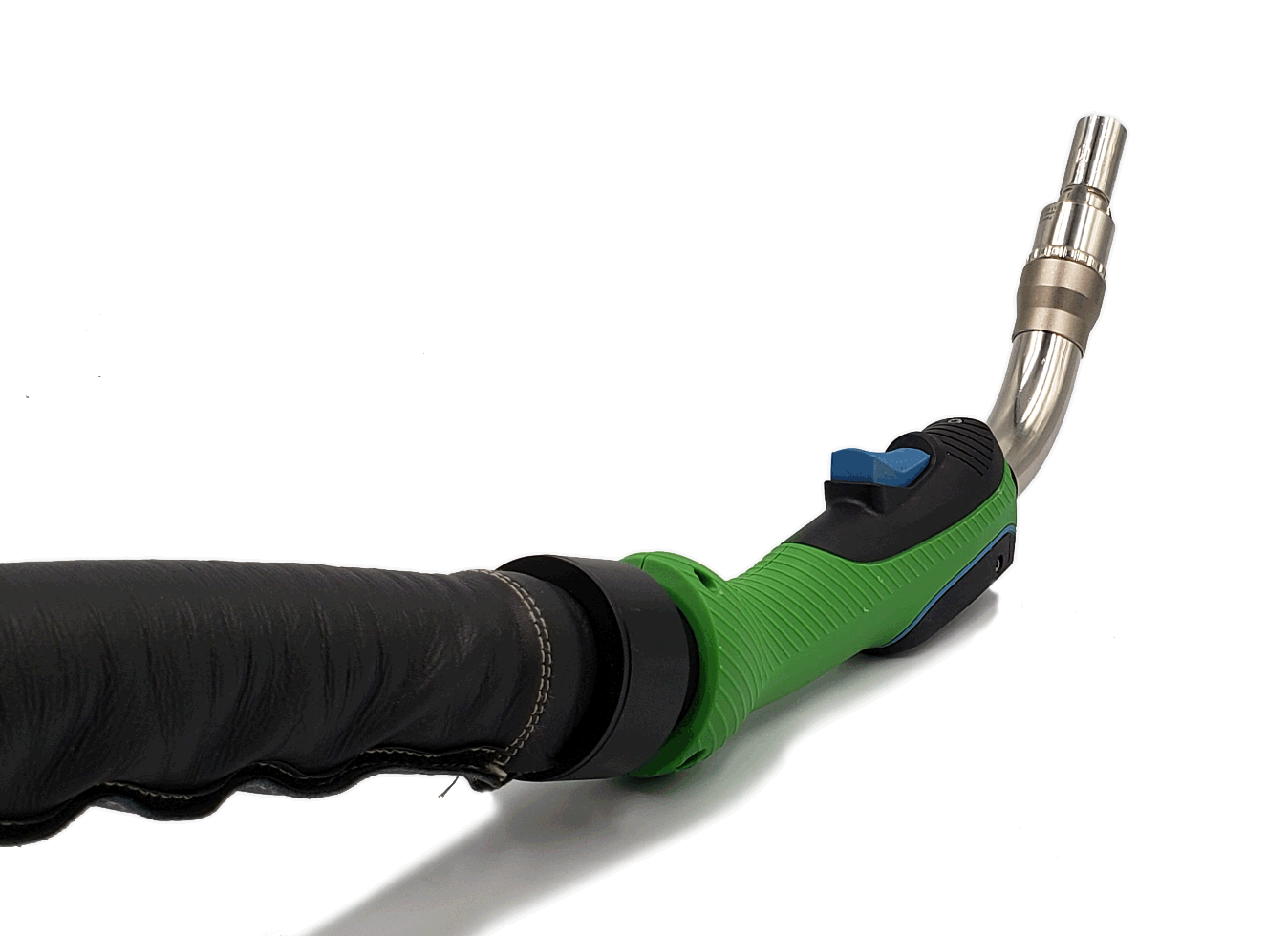

Fume extraction torch

Light weight – only 1,1 kg

CO2 – 280 Amp

250 Amp Mixed gases

100% Duty cycle

Air cooled

Specifications

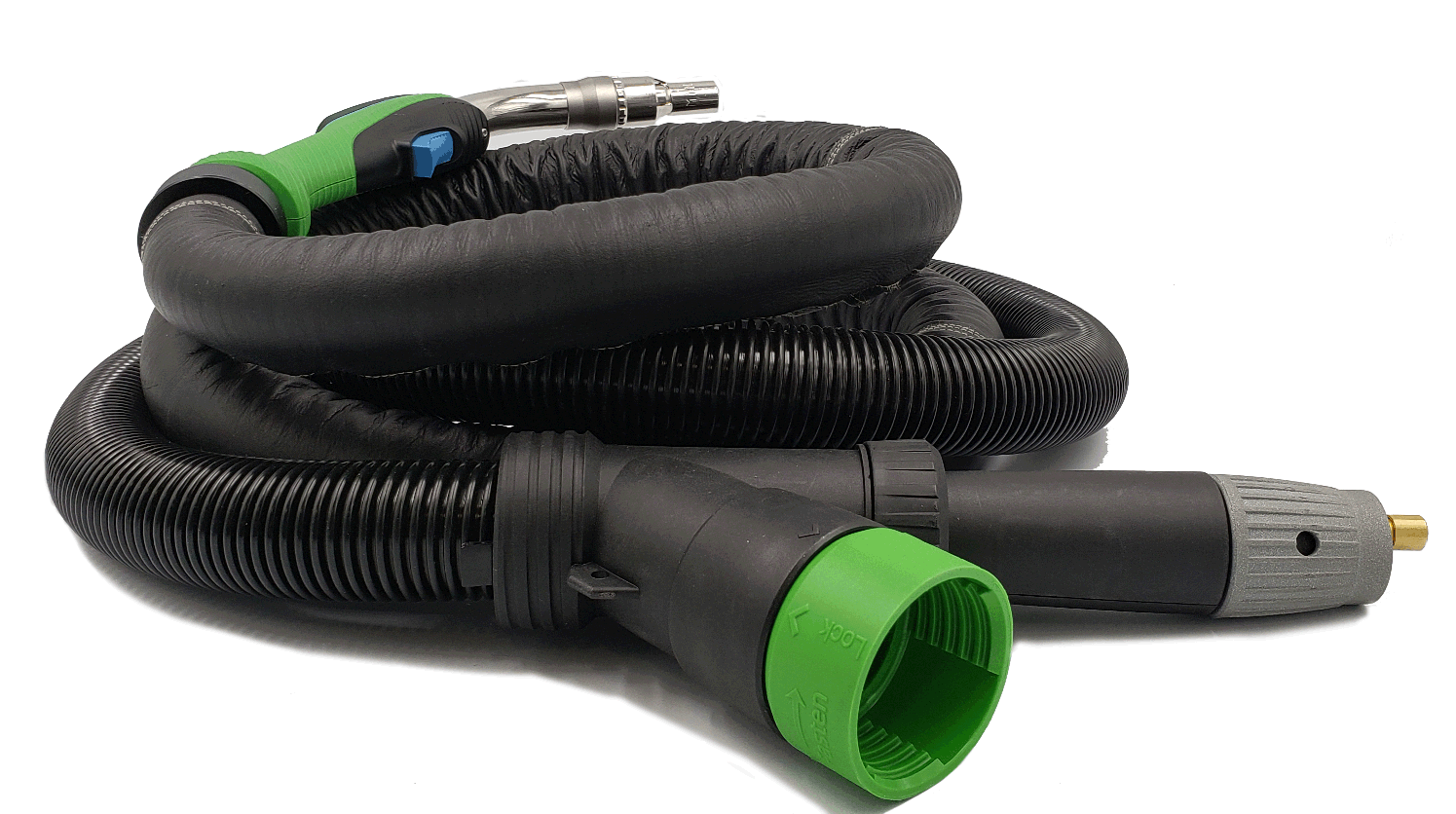

Fume extraction welding torch gun with flexible hose

CO2 – 320 Amp

300 Amp Mixed gases

100% Duty cycle

Air cooled

Specifications

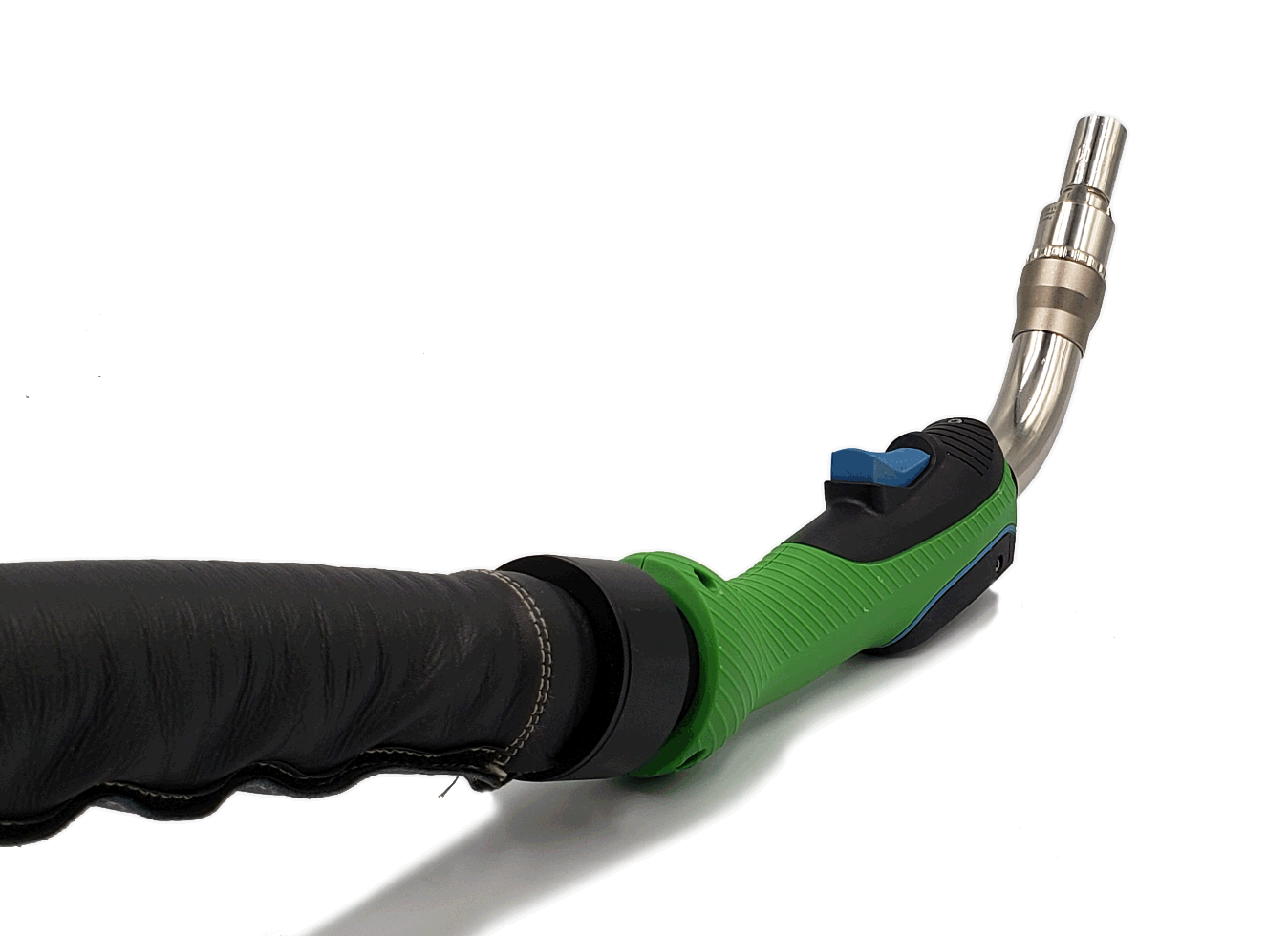

Fume extraction welding torch gun with flexible hose

CO2 – 550 Amp

500 Amp Mixed gases

100% Duty Cycle

Water cooled

Specifications

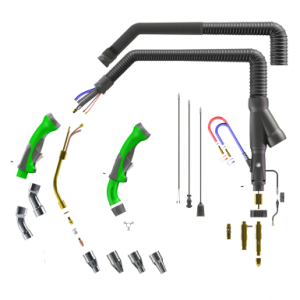

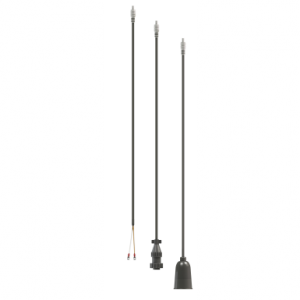

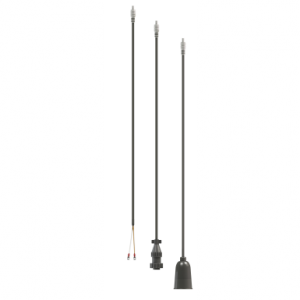

8TE-17 TIG EXTRACTOR- Air COOLED

DC – 140 AMP, AC/DC – 100 AMP, DUTY CYCLE – 35%

Specifications:

Reduces Welding Fume Up To 95%.

Same convenient handle as regular 8XT gun.

Various switch modules are available.

Extreme Flexible hose on the first meter.

Standard TIG consumables.

The 8TE TIG Fume Extractors protect the welders and other workers in the factory from harmful fumes

and metals like Aluminium, Chromium, Iron, Manganese, and Nickel which are possibly released during the welding process.

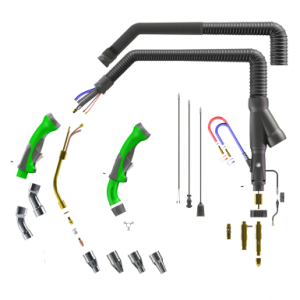

8TE-35 TIG EXTRACTOR- Water Cooled

DC – 320 Amp, AC/DC – 230 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 95%.

Same convenient handle as a regular 8XT gun.

Various switch modules are available.

Extreme Flexible hose on the first meter.

Standard TIG consumables.

The 8TE TIG Fume Extractors protect the welders and other workers in the factory from harmful fumes

and metals like Aluminium, Chromium, Iron, Manganese, and Nickel which are possibly released during the welding process.

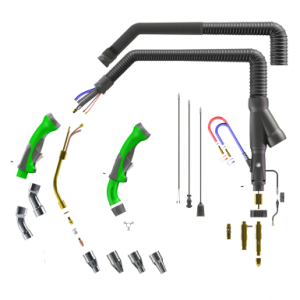

8TE-30 TIG EXTRACTOR – Water COOLED

DC – 320 AMP, AC/DC – 330 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 95%.

Same convenient handle as regular 8XT gun.

Various switch modules are available.

Extreme Flexible hose on the first meter.

Standard TIG consumables.

The 8TE TIG Extractors protect the welders and other workers in the factory from harmful fumes

and metals like Aluminium, Chromium, Iron, Manganese, and Nickel which are possibly released during the welding process.

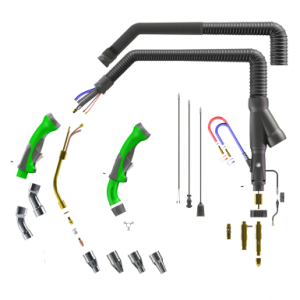

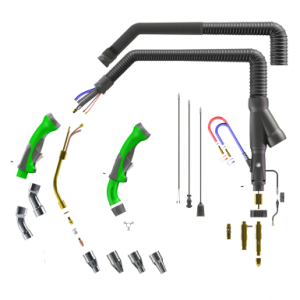

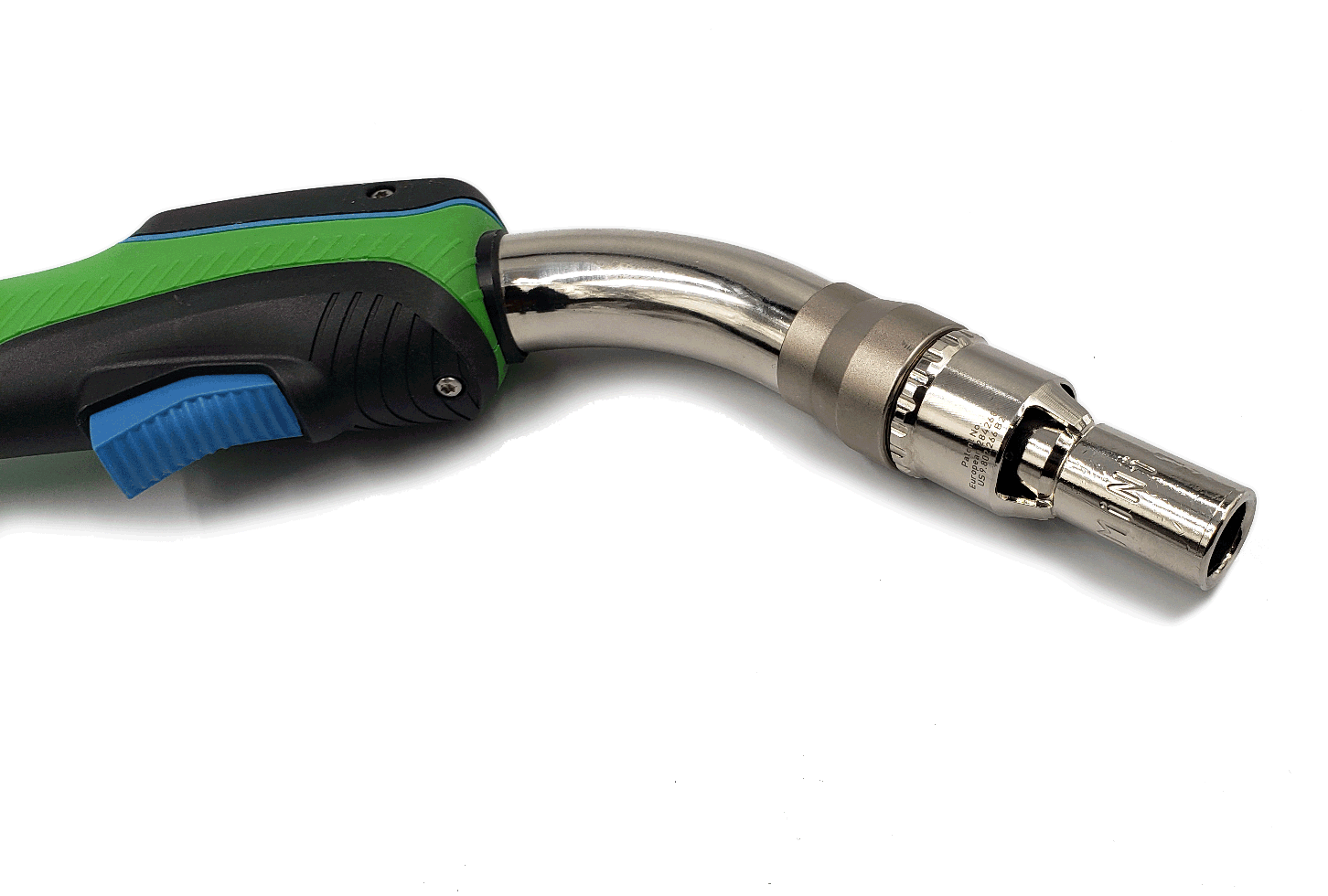

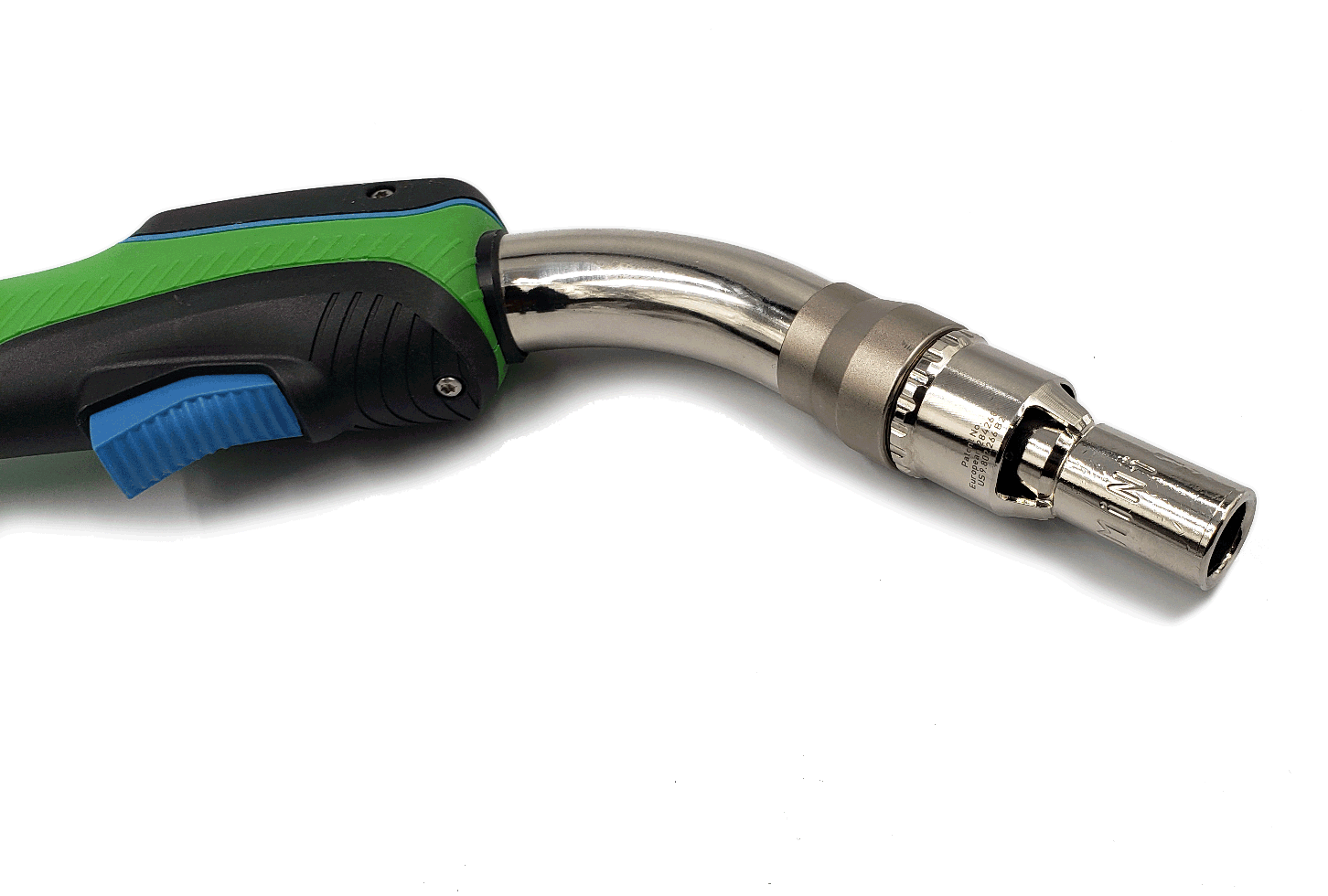

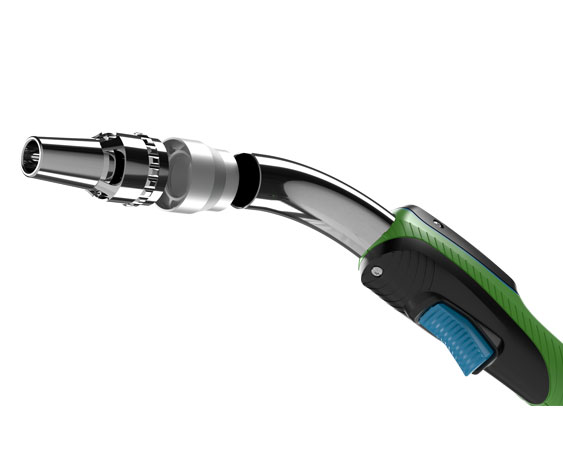

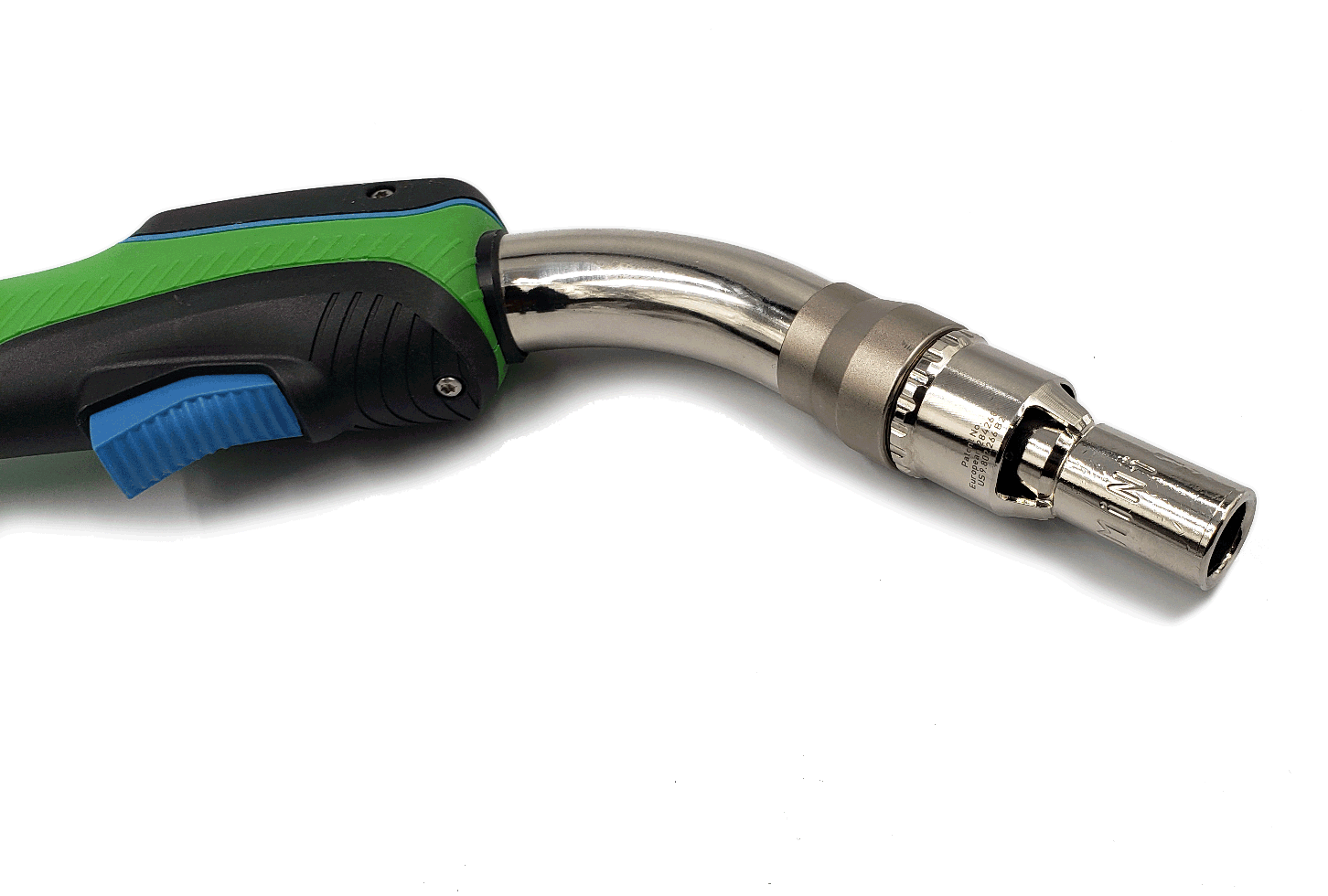

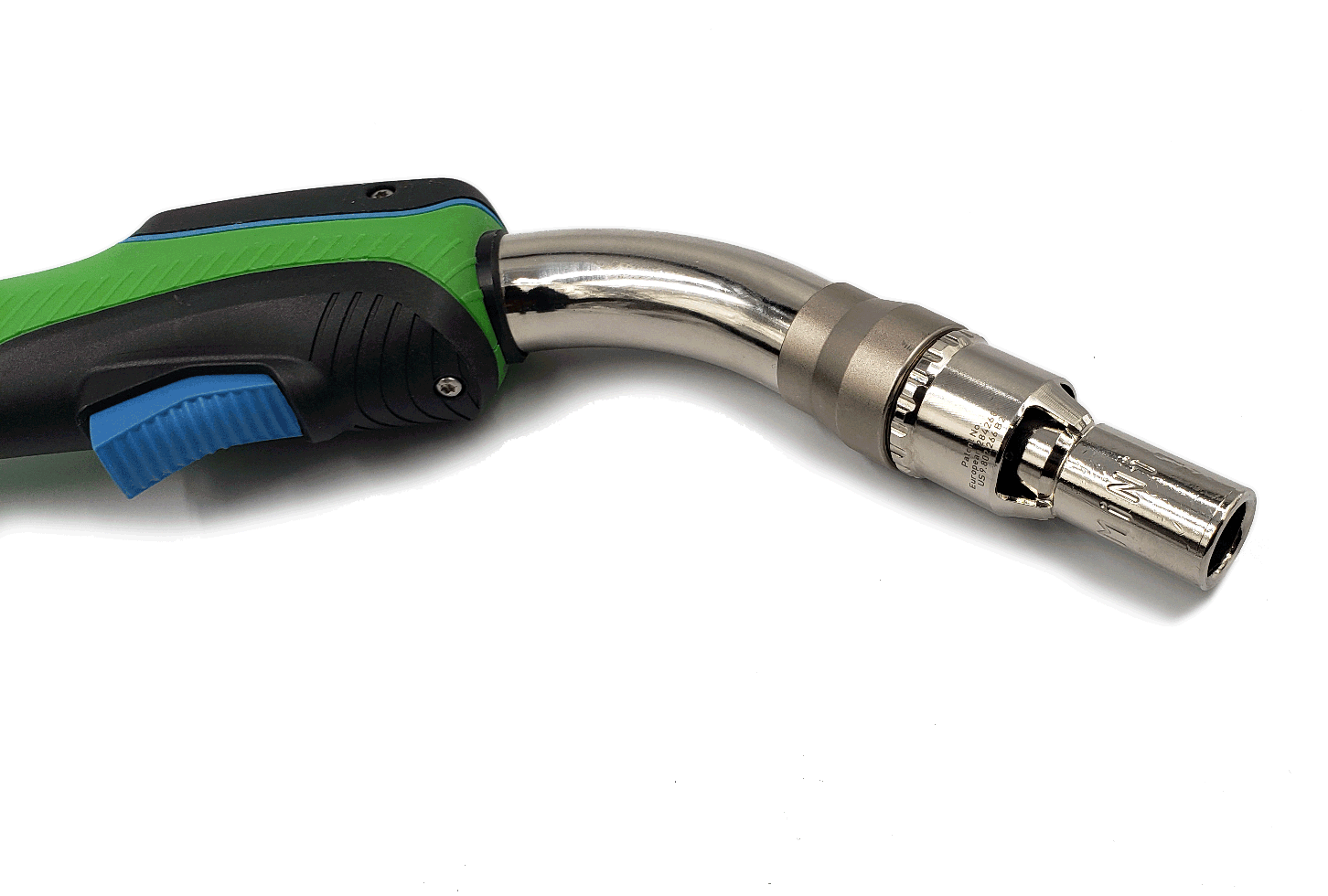

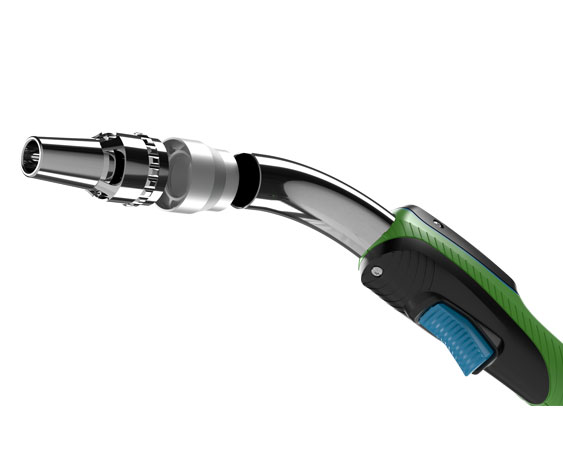

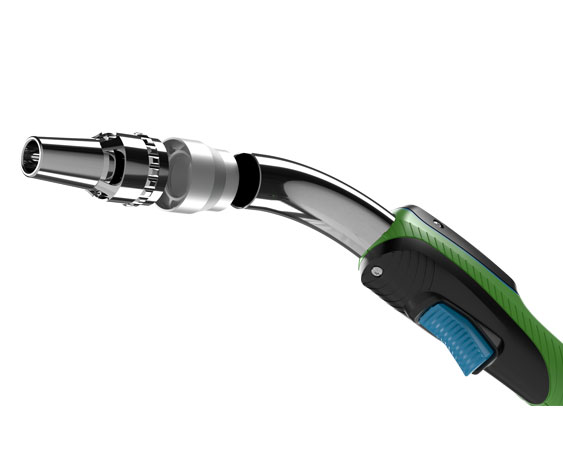

The Translas 8XE MINI 200 is the lightest MIG fume extraction gun on the market only 2.4 lb.

8XE MINI 200 MIG Fume Extraction Gun Air Cooled

CO2 – 230 AMP, MIXED GASES – 200 AMP, DUTY CYCLE – 100%

Weight*: 2.4 lb

The 8XE MINI 200 MIG fume extraction gun integrates the most efficient fume extraction structure in the welding industry. The gun comes with three different angles, 30°, 45°, and straight. The 8XE 200 MINI MIG Extractor, combined with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source. It provides the safest and most effective solution for welders and workers to breathe CLEAN AIR and enjoy better work environments.

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for a longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle designs 12mm and 14mm for optimal performance and durability

* The gun’s weight is measured 3’ above the ground

8XE MIG 400 Fume Extraction Gun – AIR-COOLED

CO2 – 420 AMP, MIXED GASES – 400 AMP, DUTY CYCLE – 100%

Weight*: 3.28 lb

The 8XE 400 MIG fume extraction gun integrates the most efficient fume extraction structure in the welding industry. The gun comes with three different angles, 30°, 45°, and straight. The 8XE 400 MIG Extractor, combined with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source. It provides the safest and most effective solution for welders and workers to breathe CLEAN AIR and enjoy better work environments.

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for a longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle designs 14mm and 17mm for optimal performance and durability

* The gun’s weight is measured 3’ above the ground.

8XE MINI 250 MIG Fume Extraction Gun – AIR COOLED

CO2 – 280 AMP, MIXED GASES – 250 AMP, DUTY CYCLE – 100%

Weight*: 2.9 lb

The 8XE MINI 250 MIG fume extraction gun integrates the most efficient fume extraction structure in the welding industry. The gun comes with three different angles, 30°, 45°, and straight. The 8XE 250 MINI MIG Extractor, combined with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source. It provides the safest and most effective solution for welders and workers to breathe CLEAN AIR and enjoy better work environments.

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for a longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle designs 14mm and 17mm for optimal performance and durability

* The gun’s weight is measured 3’ above the ground.

8XE MIG 500 Fume Extraction Gun – Water COOLED

CO2 – 500 AMP, MIXED GASES – 500 AMP, DUTY CYCLE – 100%

Weight*: 3.7 lb

The 8XE 500 MIG fume extraction gun integrates the most efficient fume extraction structure in the welding industry. The gun comes with three different angles, 30°, 45°, and straight. The 8XE 500 MIG Extractor, combined with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source. It provides the safest and most effective solution for welders and workers to breathe CLEAN AIR and enjoy better work environments.

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for a longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle designs 14mm and 17mm for optimal performance and durability

* The gun’s weight is measured 3’ above the ground.

HIGH-PERFORMANCE CENTRAL VACUUM SYSTEMS

Translas has a complete range of central high vacuum fume extraction

systems ranging from 5HP to 75HP units which will handle 5 to 40+

technicians using welding guns at the same time.

KEY BENEFITS:

• Ideal for production shops with 5 to 40+ users welding at the same time.

• 10 to a twin 75HP centrifugal multi-stage pump units can be set at various

vacuum levels from 5” HG

(68” water column) for short pipe runs to 10” HG (135” water column) to

offset friction losses on long pipe runs.

• Large aluminum impellers and fabricated housings result in a vacuum

pump that is far more efficient than competitive products (which

typically have smaller steel impellers and sections held together with

tie-rods).

• Comes equipped with cartridge filters, automatically compressed air pulse

jet cleaning, and primary cyclonic separation.

• Our industrial-grade induction motors have a 20,000+ hours rating.

• Captures dangerous welding fumes before they enter the welder’s

breathing zone.

• Ideal for MIG, TIG, arc, and robotic welding.

• No lost production time moving large fume extraction arms every time

the welder changes position.

• Source capture welding gun at 100 CFM or welding attachments only

require 80 CFM; eliminating the need for costly air makeup

systems required with high volume systems.

• Several filter options are available, including combination cyclone

separator and polyester cartridge filters with automatic pulse jet

cleaning.

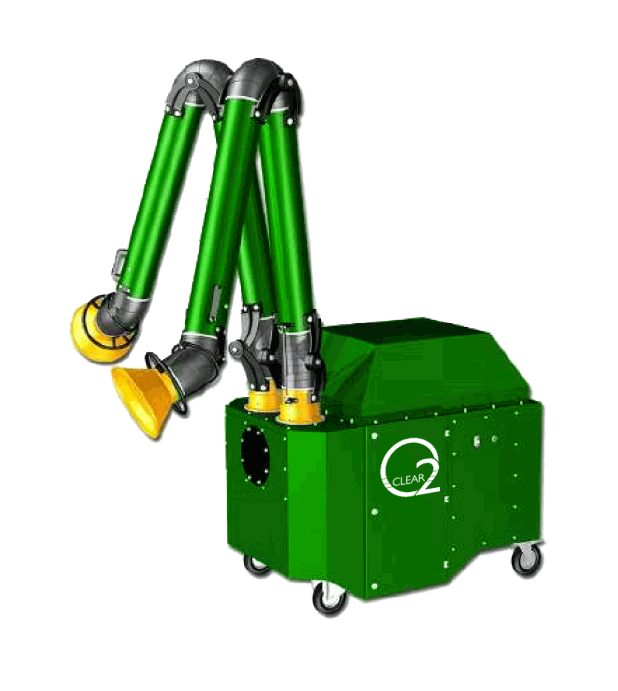

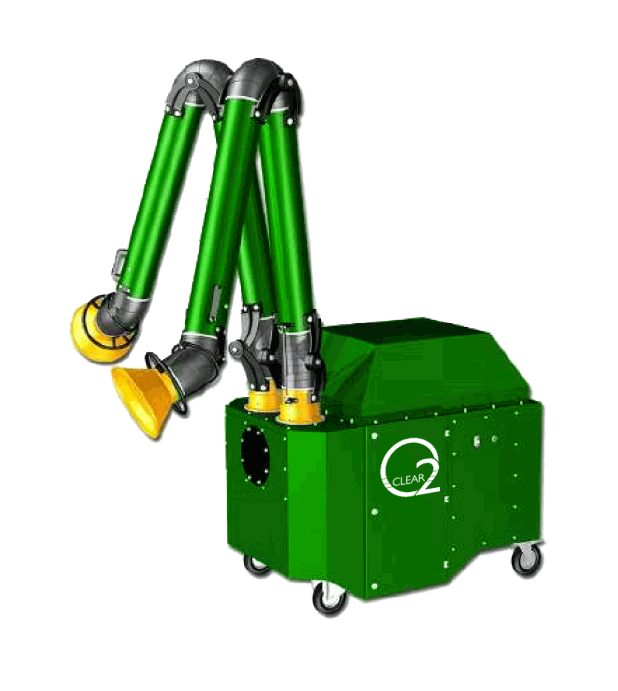

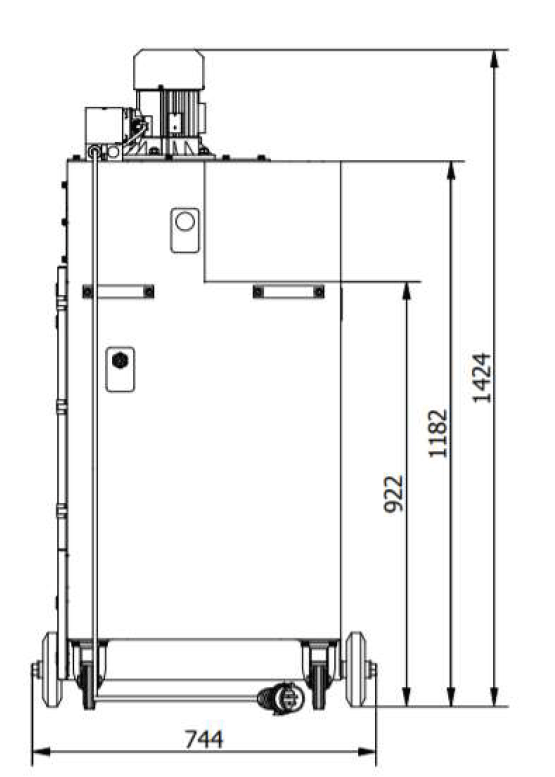

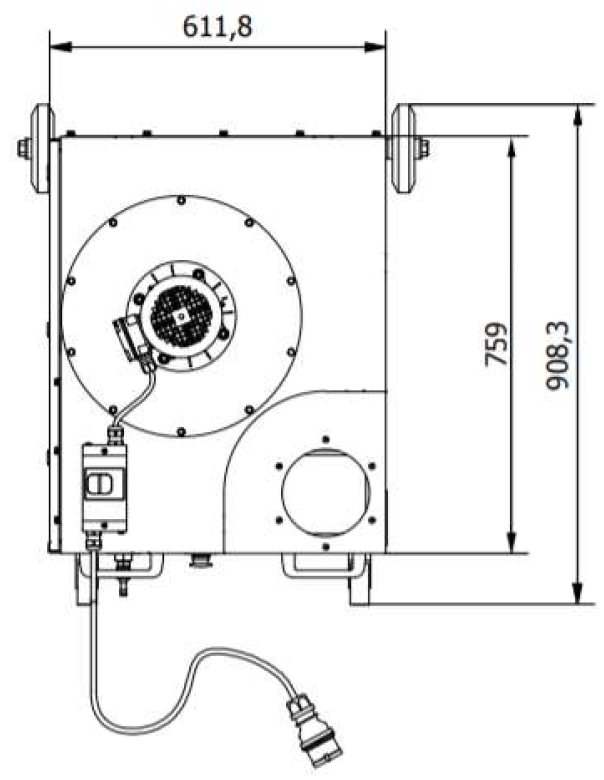

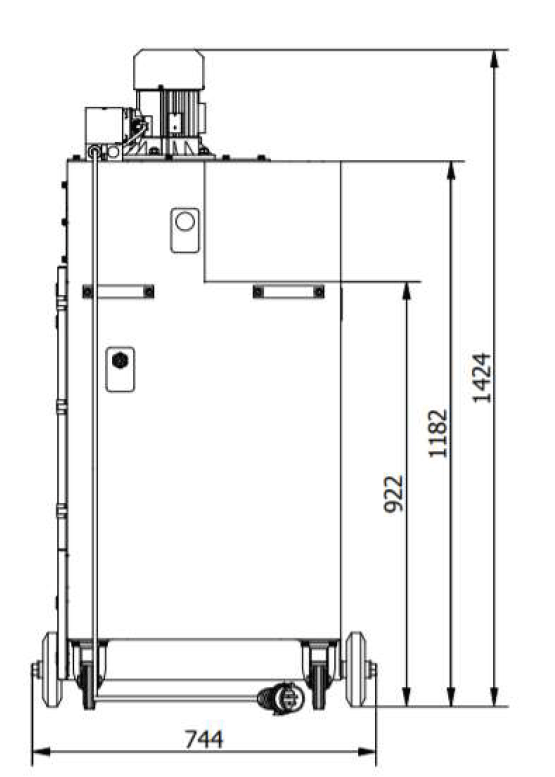

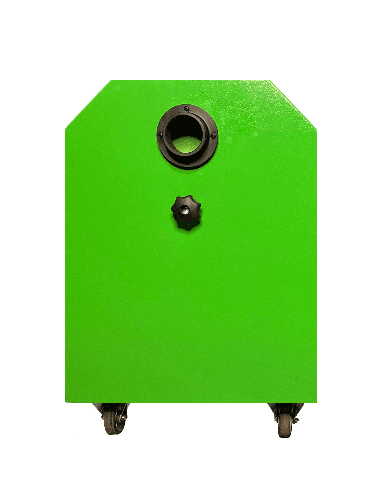

The ClearO2 Giant Portable unit is available with a power supply of 208-240, 460 & 575 volts

GIANT PORTABLE FUME EXTRACTOR

Translas’s portable fume extractor “Giant” is designed to capture and

filter dry impurities created during welding, grinding and the cutting of

metals.

• Meets OSHA air quality standards and increases health and safety

standards by minimizing hazards that cause respiratory ailments

• Available with two arm options: 1 x 8-inch arm or 2 x 6-inch arms.

Self-supporting joints and flexible hoses for easy placement with

smooth bore tubing for unimpeded air movement.

• 1200 CFM at hood for powerful performance.

• Excellent three-stage filtration: aluminum mesh pre-filter, second

polyester cartridge filters and final carbon after the filter. Manual pulse

jet cleaning comes standard and an optional HEPA upgrade available.

• Unit reduces facility maintenance costs by eliminating smoke and

dust before particles to settle on equipment and work surfaces

The ClearO2 Rollout Portable unit is available with a power supply of 115 volts

ROLLOUT PORTABLE MOBILE WELDING FUME EXTRACTION UNIT

Translas’s Rollout portable welding fume extraction system is designed to capture and

filter dry impurities created during welding, grinding and the cutting of

metals.

• Meets OSHA air quality standards and increases health and safety

standards by minimizing hazards that cause respiratory ailments.

• Standard arm measures 6” in diameter and fully extends to 10-

feet. Other sizes are also available on request.

• 700 CFM at hood for powerful performance.

• Excellent three-stage filtration: aluminum mesh pre-filter, second

polyester cartridge filters and final carbon after the filter. Manual pulse

jet cleaning comes standard and an optional HEPA upgrade available.

• Unit reduces facility maintenance costs by eliminating smoke and

dust before particles to settle on equipment and work surfaces.

The ClearO2 T100 unit is available with a power supply of 220V-240V (T100) and CSA and CE certified. W3 Under construction.

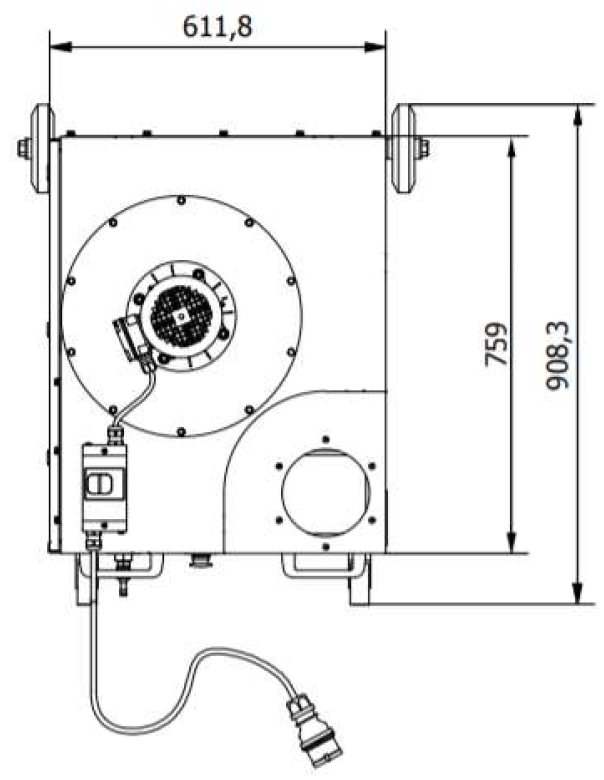

Specifications

The ClearO2 T100 is designed to accompany the 8TE TIG Extractor from Translas. With the combination of the 8TE TIG Extractor range of welding fume torch and ClearO2 T100 unit we capture between 90% and 95% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 30 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 T100 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic Start/Stop function to preserve energy and to synchronize the unit with the 8TE TIG Extractor is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder option, the machine automatically starts working.

Light and Mobile

The ClearO2 T100 unit is designed to serve the needs of a single welder, who needs to change their work-place.

The ClearO2 T200 unit is available with a power supply of 220V-240V (T200) and CE and W3 certified.

Specifications

The ClearO2 T200 is designed to accompany the 8TE TIG Extractor from Translas. With the combination of the 8TE TIG Extractors range of welding fume torches and ClearO2 T200 unit we capture between 90% and 95% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 45 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 T200 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic Start/Stop function to preserve energy and to synchronize the unit with the 8TE TIG Extractor is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder option, the machine automatically starts working.

Continuous rated motor

The electric motor of the unit is designed to work continuously without losing its power. Due to the automatic cleaning function and the simplified motor system, the maintenance of the unit is minimal, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light and Mobile

The ClearO2 T200 unit is designed to serve the needs of two welders, who need to change their work-place. Examples for such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 45kg – let the welder move the unit with ease to the next working location.

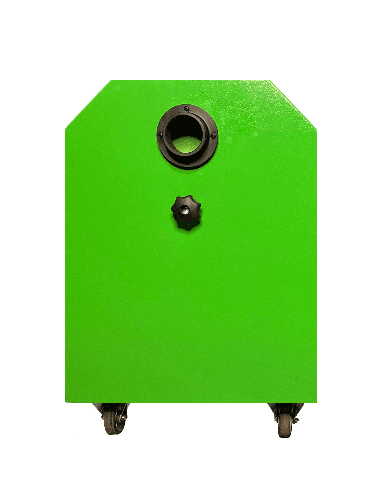

ClearO2 Two-welder mobile filtration unit

Designed for the 7XE Extractor torch

Exceptional filter efficiency IFA >99.8%

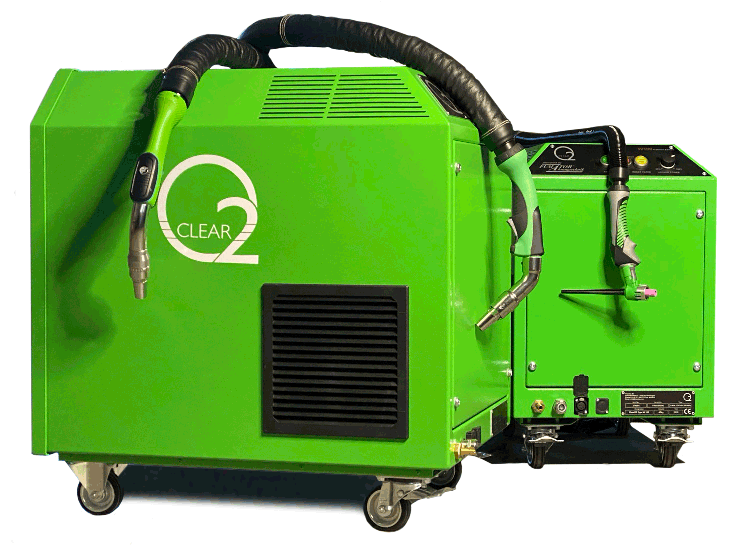

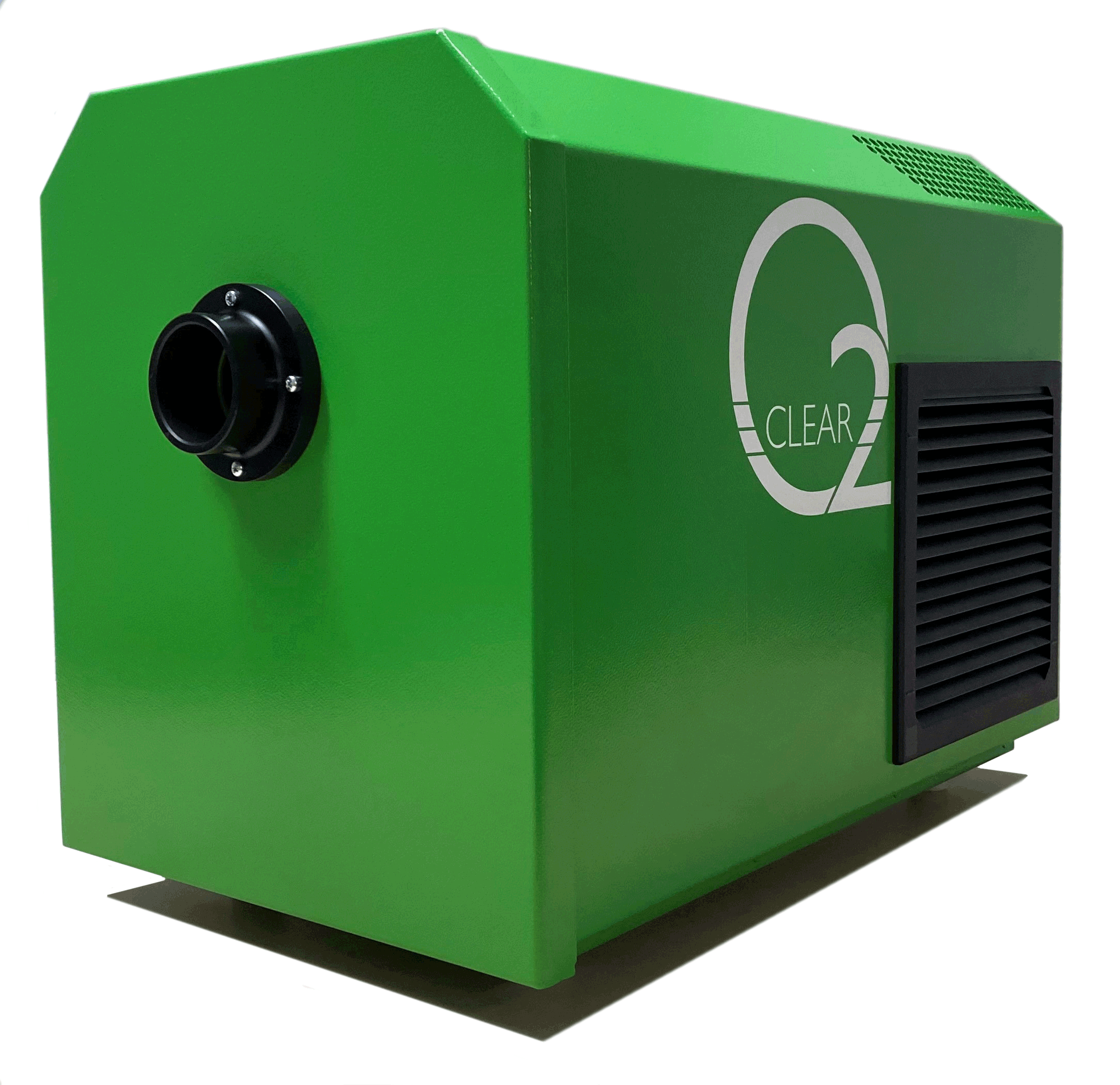

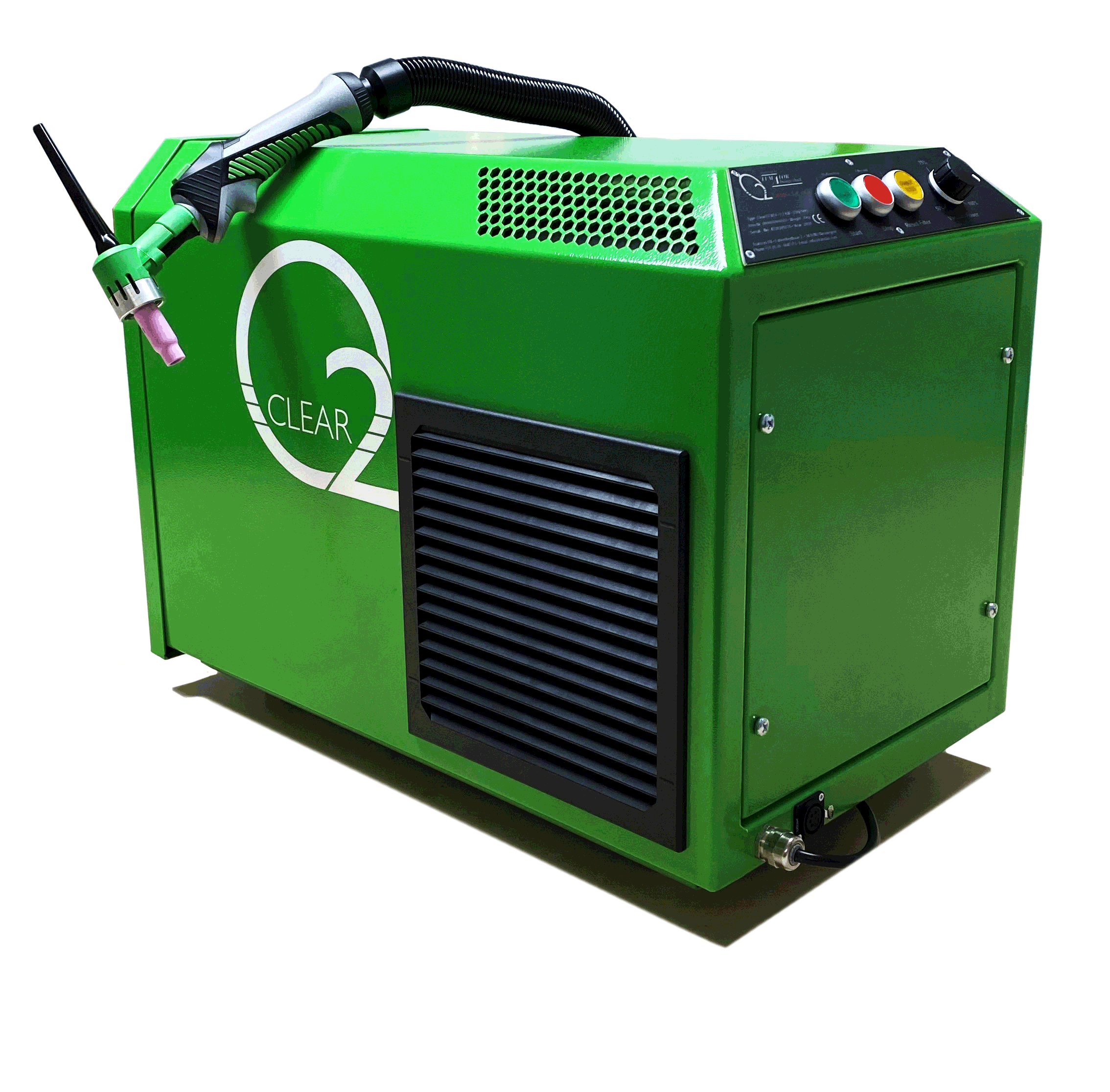

Specifications

The ClearO2 W200 is designed to accompany the 8XE MIG and 8XR MIG Cobot Extractors from Translas. With the combination of the 8XE MIG and 8XR MIG Cobot Extractors range of welding fume torches and ClearO2 W200 units, we capture between 90% and 98% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 58 kg – and its four wheels with two lockable.

Automatic Unit

The ClearO2 W200 unit has an automatic cleaning function by reverse compressed air pulse. The moment the pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic start/stop function to preserve energy and to synchronize the unit with the 8XE MIG and 8XR MIG Cobot Extractors is a standard on the ClearO2 units. The moment the gun is out of the specially designed torch holder, the machine automatically starts working. The gun holder is designed to work only with the 8XE MIG and 8XR MIG Cobot Extractors

Continuous Rated Motor

The electric motor of the unit is designed to work continuously without losing power. Maintenance on the unit is minimal due to the automatic cleaning function and the simplified motor system, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light And Mobile

The ClearO2 W200 unit is designed to serve the needs of a welder, who needs to move around their workplace. Examples of such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 58kg – allow the welder to move the unit with ease to the next working location.

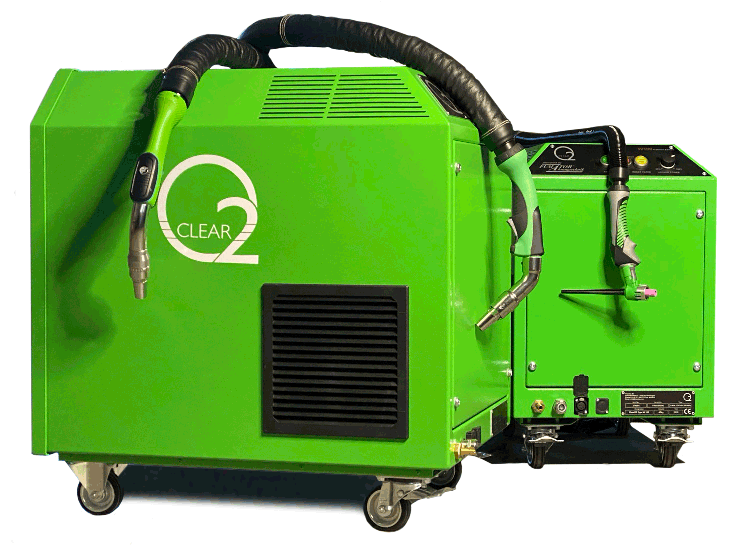

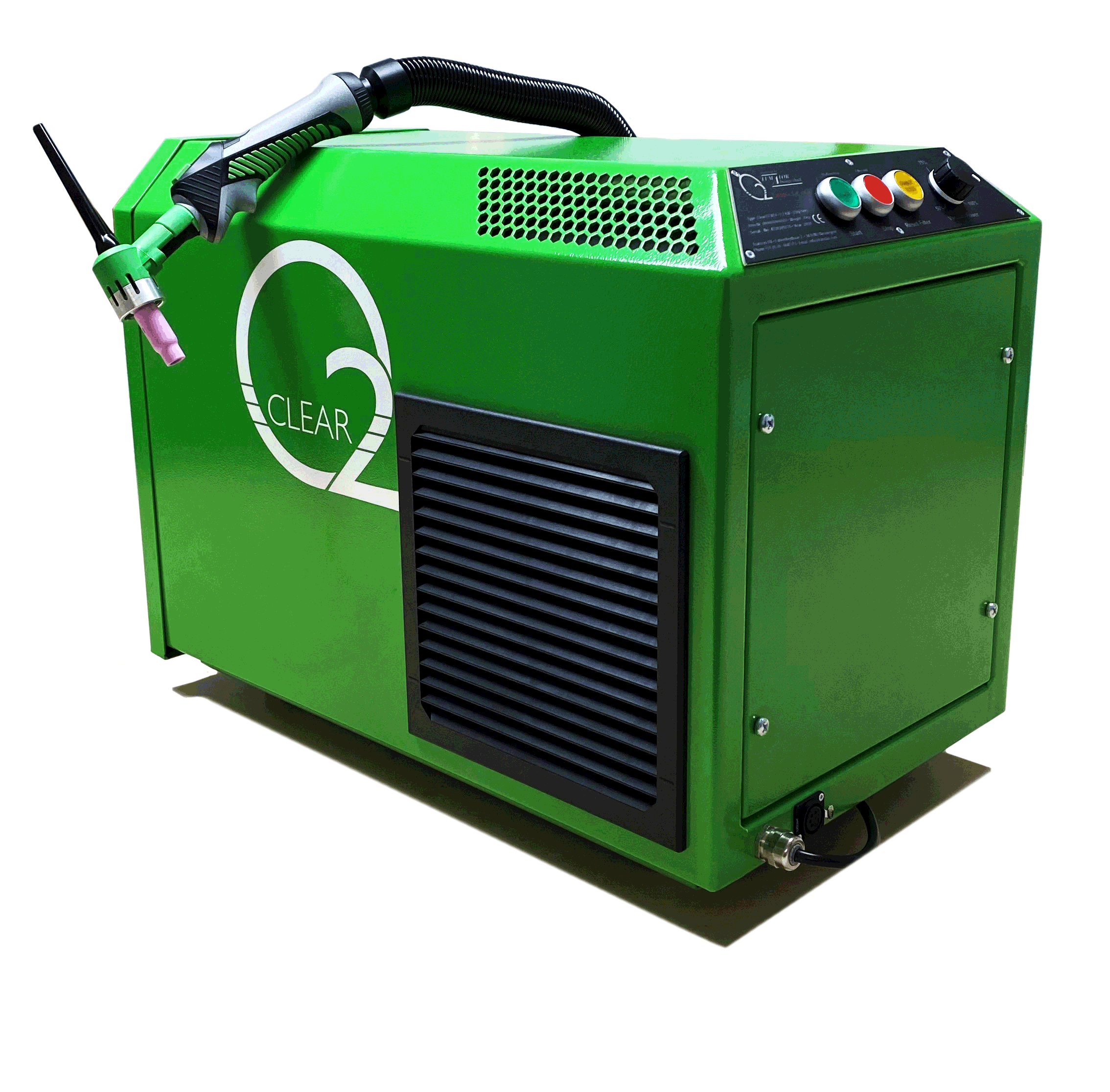

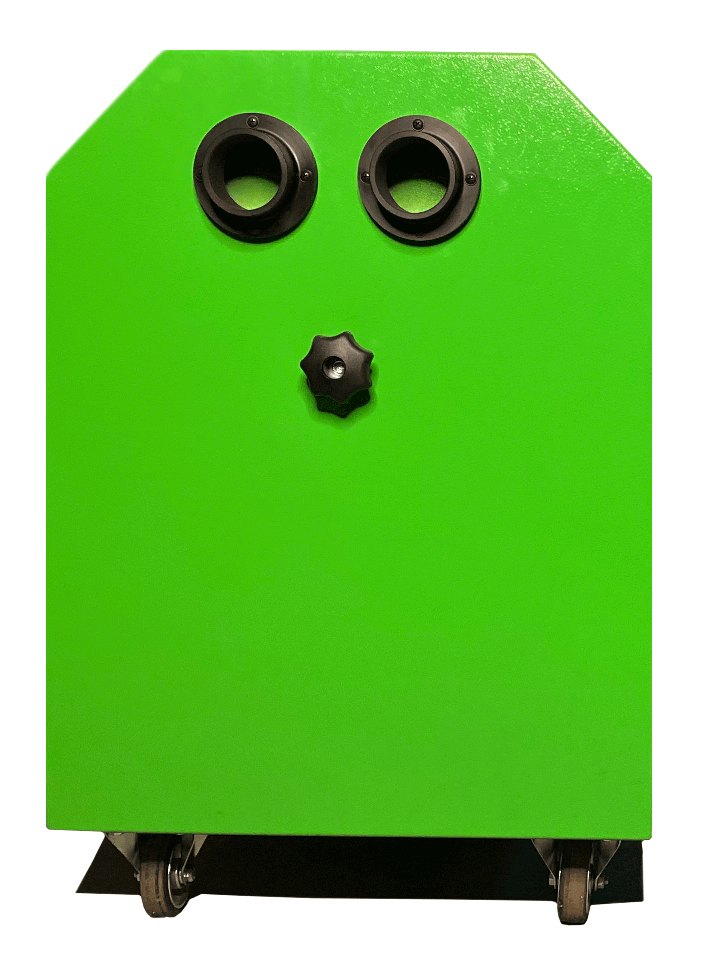

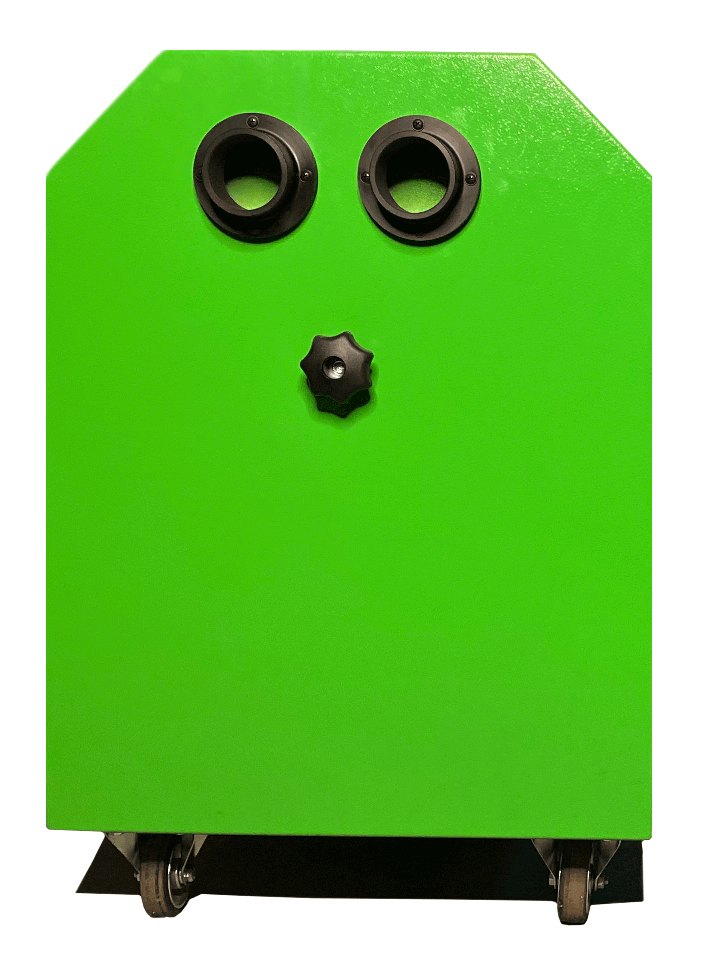

The ClearO2 unit is available with a power supply of 220V-240V (W100) or 380-480V (W150) and CE and W3 certified.

Specifications

The ClearO2 W100/ W150 is designed to accompany the 8XE MIG and 8XR MIG Cobot Extractors from Translas. With the combination of the 8XE MIG and 8XR MIG Cobot Extractors range of welding fume torches and ClearO2 W100/150 units, we capture between 90% and 98% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 45 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 W100/ W150 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic Start/Stop function to preserve energy and to synchronize the unit with the 8XE MIG and 8XR MIG Cobot Extractors is a standard on the ClearO2 units. The moment the gun is out of the specially designed torch holder option, the machine automatically starts working.

Continuous rated motor

The electric motor of the unit is designed to work continuously without losing its power. Due to the automatic cleaning function and the simplified motor system, the maintenance of the unit is minimal, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light and Mobile

The ClearO2 W100/ W150 units are designed to serve the needs of a single welder, who needs to change their workplace. Examples of such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 45kg – let the welder move the unit with ease to the next working location.

Ball valve to reduce the suction flow

Coupler for suction hose black tbv Ø51mm unit side

Coupler to extend the suction hose Ø51mm

Extension cable auto start/stop 5-p plug W-serie

Specifications

Filter W-serie ClearO2

Specifications

Filtermat W-serie ClearO2

Specifications

Pressure reducing valve 5-15bar 1/4-NP7.2

Sensing cable auto start/stop 4mtr W-serie

Specifications

Suction hose for the ClearO2

Specifications

Torch holder for automatic start/stop

Specifications