If you have a company, it means you have processes to optimize, even if your company consists only of you. The only difference is that the more people you have, the more complicated the work flow becomes and there is always a part of the process that can be done better. Good companies want to do what they do excellently, not just well. Excellency is what Translas is going for and, in order to achieve it, you first have another major task – to connect your team with the idea of change. This is not an easy task. Marcel Hamoen, who is responsible for the implementation of ERP (Enterprise Resource Planning) at Translas, has outlined the steps of the process below.

As a company that always looks for improvements, we have noticed a few significant benefits.

Customer benefits – by using the new ERP add-ons, we are expecting to achieve shorter delivery times by the end of the year. The other benefit for the customer is that ERP is one of the main reasons Translas can maintain its price range while still delivering high-quality torches.

Internally, we are happy to notice a shift in attitude. People within all of our departments are now more open to change. This will make it much easier to implement future improvements and to achieve additional customer benefits. “First we started with ‘Lean’ but now we realize that the more you think of improvements, the more you see improvements.” This change in attitude is what keeps us on top.

First of all, there are initial steps to be taken. Before anything else, you need to convince yourself how badly the change is needed. If you’re not convinced, you have no chance of convincing others. This is how it works at Translas:

1) Make a clear flow line – the first step is about analysing. You need to make a clear and detailed line of a process flow within your company. Only after you have this down in black and white can you say whether there are any steps that are unnecessary or repetitive. Very often two departments repeat the same step. It is a shame to be wasting your time in such a way. This step will define what kind of ERP solution your company needs.

2) Don’t just jump into a solution – after understanding which ERP solution you need, don’t just jump in and start implementing it. It is very important that the solution you find fits the workflow within your company. ERP can provide add-ons that are a good fit for one company but may not be the right fit for your company. This can have a tremendous effect on your Return on Investment (ROI). Technology is an expensive investment that can also earn you a lot, but only if used intelligently. Don’t blindly trust any one, particular ERP adviser.

3) Be honest about it – after the analysis is completed is the best moment to discuss your findings with the team. Don’t stress them out. Explain to them what the potential benefits would be and make it clear that there will be testing before any final decision is taken. Otherwise, you might find resistance from the other side straight from the beginning.

4) Create a demo environment – a demo environment consists of copying your database into the particular ERP solution you want to try. Most of the time this solution is an add-on to your software. Then, start testing it with the people who will be using it the most.

5) Implement (after a successful demo) – the last step is, of course, to implement the add-on. In this step, you need to provide further training for those who took part in the demo. After they have the hang of it, it will be much easier to transfer the knowledge to the rest of the department.

It is human nature to avoid change. Therefore, it is very unlikely that you’ll NOT hear questions, such as: “But is it really necessary?” For the same reason, there is no best time to introduce a change in the workflow. You just have to know how to get people’s commitment.

Know Your Numbers

As mentioned before, there are two important questions to answer before you share anything with the team: The first question is – “Is it really necessary to have this?” The second question is – “What does the business case show? Do I get the ROI I am looking for?” After you have this information and you have convinced yourself, you can back up your words.

Involve The Influencers.

Start with the demo in order to interact with those who will be using it eventually. Always pick people that are respected and have formal or informal influence on the rest of their department. If they’re convinced, then it will be much easier to implement the solution down the line; the need for this increases when you have conservative eyes observing you.

Ask For Feedback, And Especially Negative Feedback.

Why is negative feedback so important? Everyone gets used to the things they like much quicker than to the things they do not like. If you can eliminate or modify the process so that it best suits your team, you will see less resistance from them.

Take Your Time.

“If it takes a long time, that doesn’t matter. I have to see in their eyes that they’re ready for it. Because you can have the greatest software, but it’s the people who make it work.”- Marcel Hamoen.

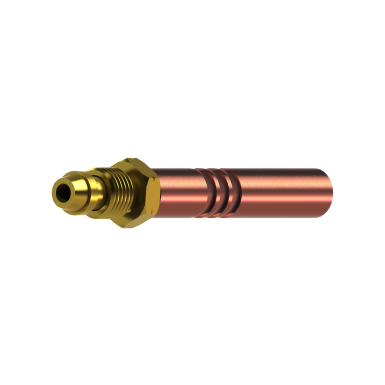

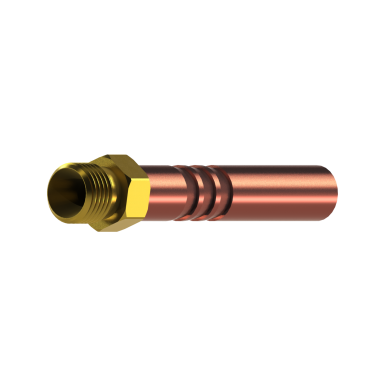

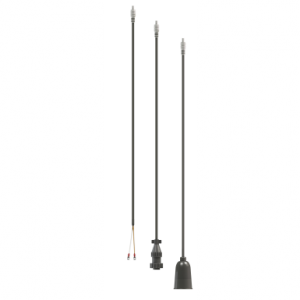

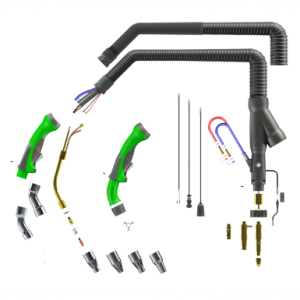

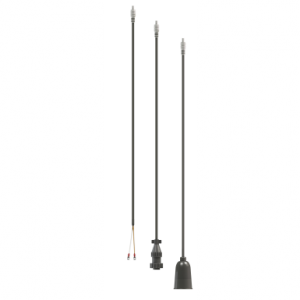

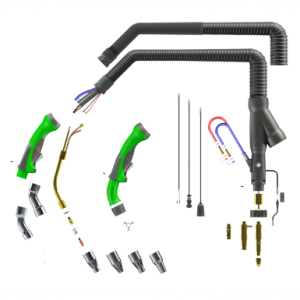

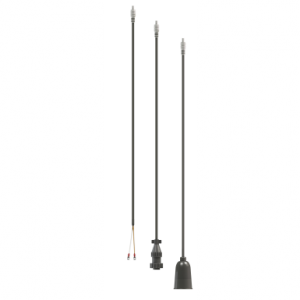

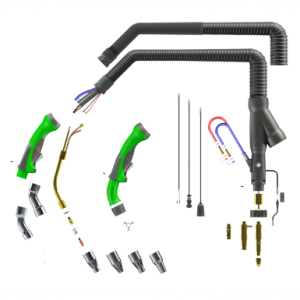

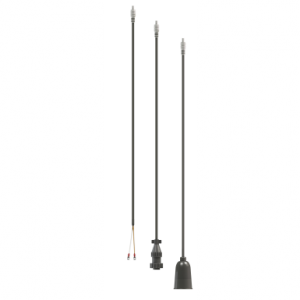

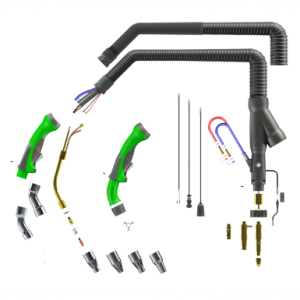

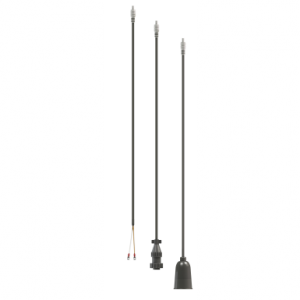

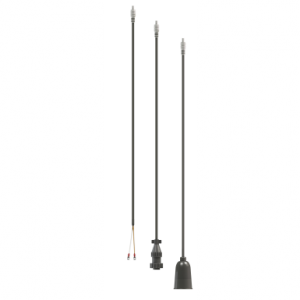

Welding torches and welding equipment from Translas are distinctive in ergonomics, durability, performance, shape, and appearance.

35% Duty cycle

160 Amp. – DC

120 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

160 Amp. – DC

120 Amp. – AC/DC

Air cooled

35% Duty cycle

140 Amp. – DC

100 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

140 Amp. – DC

100 Amp. – AC/DC

Air cooled

35% Duty cycle

80 Amp. – DC

60 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

80 Amp. – DC

60 Amp. – AC/DC

Air cooled

35% Duty cycle

180 Amp. – DC

130 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

180 Amp. – DC

130 Amp. – AC/DC

Air cooled

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

35% Duty cycle

160 Amp. – DC

120 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

160 Amp. – DC

120 Amp. – AC/DC

Air cooled

35% Duty cycle

140 Amp. – DC

100 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

140 Amp. – DC

100 Amp. – AC/DC

Air cooled

100% Duty cycle

320 Amp. – DC

230 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

320 Amp. – DC

230 Amp. – AC/DC

Water cooled

100% Duty cycle

400 Amp. – DC

280 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

400 Amp. – DC

280 Amp. – AC/DC

Water cooled

100% Duty cycle

220 Amp. – DC

165 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

220 Amp. – DC

165 Amp. – AC/DC

Water cooled

35% Duty cycle

80 Amp. – DC

60 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

80 Amp. – DC

60 Amp. – AC/DC

Air cooled

100% Duty cycle

210 Amp. – DC

165 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

210 Amp. – DC

165 Amp. – AC/DC

Water cooled

100% Duty cycle

250 Amp. – DC

175 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

250 Amp. – DC

175 Amp. – AC/DC

Water cooled

35% Duty cycle

180 Amp. – DC

130 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

180 Amp. – DC

130 Amp. – AC/DC

Air cooled

35% Duty cycle

300 Amp. – DC

250 Amp. – AC/DC

Water cooled

Specifications

35% Duty cycle

300 Amp. – DC

250 Amp. – AC/DC

Water cooled

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

100% Duty cycle

350 Amp. – DC

250 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

350 Amp. – DC

250 Amp. – AC/DC

Water cooled

100% Duty cycle

450 Amp. – DC

360 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

450 Amp. – DC

360 Amp. – AC/DC

Water cooled

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

Specifications

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

100% Duty cycle

320 Amp. – DC

230 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

320 Amp. – DC

230 Amp. – AC/DC

Water cooled

100% Duty cycle

400 Amp. – DC

280 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

400 Amp. – DC

280 Amp. – AC/DC

Water cooled

100% Duty cycle

220 Amp. – DC

165 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

220 Amp. – DC

165 Amp. – AC/DC

Water cooled

100% Duty cycle

210 Amp. – DC

165 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

210 Amp. – DC

165 Amp. – AC/DC

Water cooled

100% Duty cycle

250 Amp. – DC

175 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

250 Amp. – DC

175 Amp. – AC/DC

Water cooled

35% Duty cycle

300 Amp. – DC

250 Amp. – AC/DC

Water cooled

Specifications

35% Duty cycle

300 Amp. – DC

250 Amp. – AC/DC

Water cooled

35% Duty cycle

110 Amp. – DC

80 Amp. – AC/DC

Air cooled

100% Duty cycle

350 Amp. – DC

250 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

350 Amp. – DC

250 Amp. – AC/DC

Water cooled

100% Duty cycle

450 Amp. – DC

360 Amp. – AC/DC

Water cooled

Specifications

100% Duty cycle

450 Amp. – DC

360 Amp. – AC/DC

Water cooled

Click on Product Sheet for configuration

1-Button

Lamelle

2-Button

3-button

4-Button Rocker

1-Button Potentiometer

Specifications

Click Product Sheet for more specifications

FLEX hose nylon braded

TPU hose reinforced

Fuel hose reinforced

Rubber hose reinforced

Silicon hose nylon braded

PROFLEX hose nylon braded

Specifications

FLEX hose nylon braded – standard 100

TPU hose reinforced 100

Fuel hose reinforced 100

Rubber hose reinforced 100

Silicon hose nylon braded 100

PROFLEX hose nylon braded 100

Ceramic cup 9/20/25F/30

Ceramic cup 17/18/26

Ceramic cup 24/24W

Ceramic cup 121/301

Ceramic cup short 121/301

Ceramic cup 450

Ceramic gas lens cup 9/20/24/24W/25F/30

Ceramic gas lens cup 17/18/18SC/26/121/301

Ceramic gas lens cup XL 17/18/26

Ceramic gas lens cup 450

Specifications

13N08 Ceramic cup 6.4mm 9/20/25F/30

13N09 Ceramic cup 7.9mm 9/20/25F/30

13N10 Ceramic cup 9.5mm 9/20/25F/30

13N11 Ceramic cup 11.1mm 9/20/25F/30

13N12 Ceramic cup 12.7mm 9/20/25F/30

13N13 Ceramic cup 15.9mm 9/20/25F/30

10N50 Ceramic cup 6.4mm 17/18/26

10N49 Ceramic cup 7.9mm 17/18/26

10N48 Ceramic cup 9.5mm 17/18/26

10N47 Ceramic cup 11.1mm 17/18/26

10N46 Ceramic cup 12.7mm 17/18/26

10N45 Ceramic cup 16.0mm 17/18/26

10N44 Ceramic cup 19.0mm 17/18/26

53N23 Ceramic cup 4.2mm 24/24W

53N24 Ceramic cup 6.4mm 24/24W

53N25 Ceramic cup 7.9mm 24/24W

53N27 Ceramic cup 9.5mm 24/24W

0315035 Ceramic cup 9.8mm 121/301

0315037 Ceramic cup 11.1mm 121/301

0315033 Ceramic cup short 8.0mm 121/301

0315034 Ceramic cup short 9.8mm 121/301

0315036 Ceramic cup short 11.1mm 121/301

0314201 Ceramic cup 9.8mm 450

0314202 Ceramic cup 12.7mm 450

0314203 Ceramic cup 15.9mm 450

3N58 Ceramic gas lens cup 6.4mm 9/20/24/24W/25F/30 10

53N59 Ceramic gas lens cup 7.9mm 9/20/24/24W/25F/30 10

53N60 Ceramic gas lens cup 9.5mm 9/20/24/24W/25F/30 10

53N61 Ceramic gas lens cup 11.1mm 9/20/24/24W/25F/30 10

53N61S Ceramic gas lens cup 12.7mm 9/20/24/24W/25F/30 10

54N18/0315080 Ceramic gas lens cup 6.4mm 17/18/18SC/26/121/301 10

54N17/0315081 Ceramic gas lens cup 8.0mm 17/18/18SC/26/121/301 10

54N16/0315082 Ceramic gas lens cup 9.5mm 17/18/18SC/26/121/301 10

54N15/0315083 Ceramic gas lens cup 11.1mm 17/18/18SC/26/121/301 10

54N14/0315084 Ceramic gas lens cup 12.7mm 17/18/18SC/26/121/301 10

54N19 Ceramic gas lens cup 17.5mm 17/18/18SC/26 10

57N75 Ceramis gas lens cup XL 9.5mm 17/18/26 5

57N74 Ceramic gas lens cup XL 12.7mm 17/18/26 5

53N88 Ceramic gas lens cup XL 16.0mm 17/18/26 5

53N87 Ceramic gas lens cup XL 19.0mm 17/18/26 5

53N89 Ceramic gas lens cup XL 23.8mm 17/18/26 5

0314301 Ceramic gas lens cup 9.8mm 450 10

0314302 Ceramic gas lens cup 12.7mm 450 10

0314303 Ceramic gas lens cup 15.9mm 450

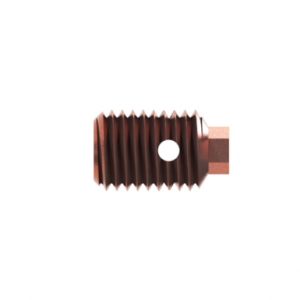

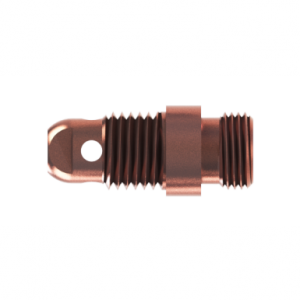

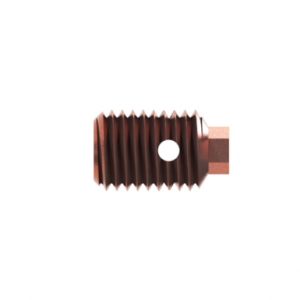

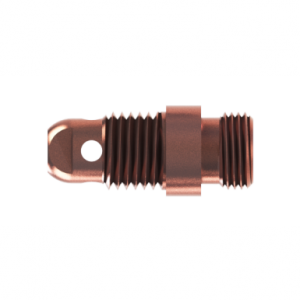

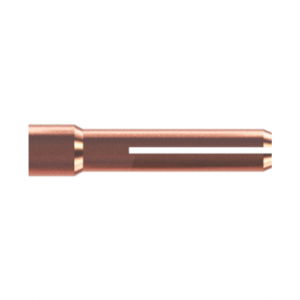

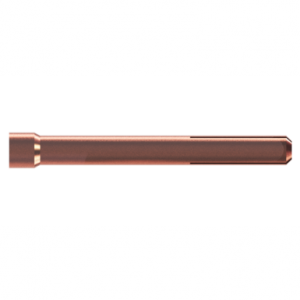

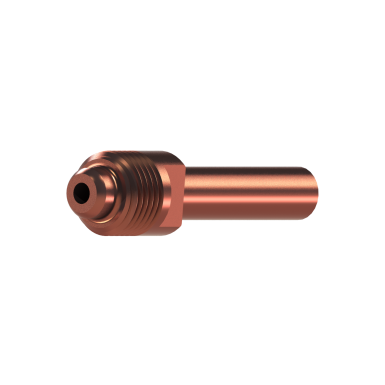

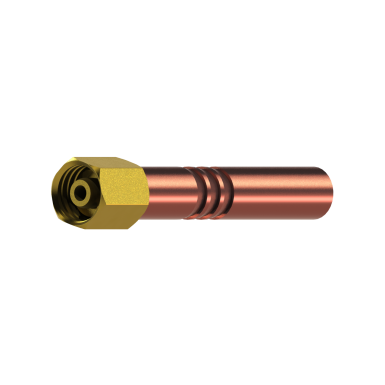

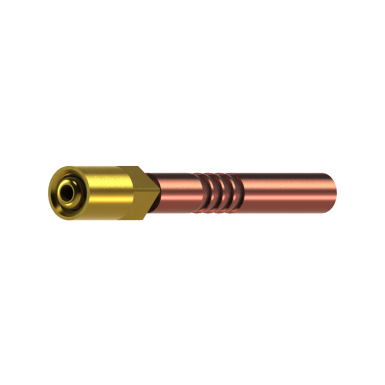

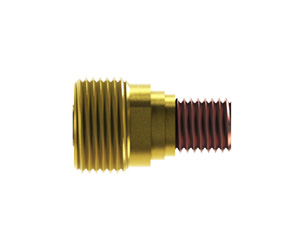

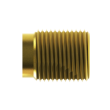

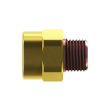

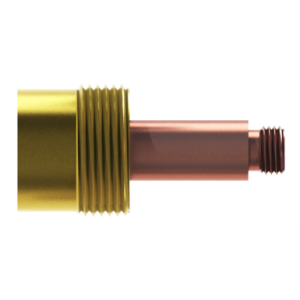

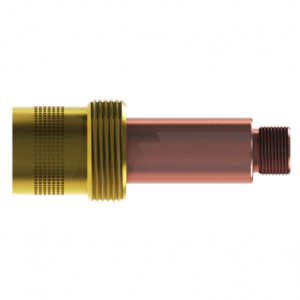

Collet body 9/20/25F/30

Collet body 17/18/26

Collet body stubby 17/18/26

Collet body 24/24W

Specifications

13N26 Collet body 1.0mm 9/20/25F/30

13N27 Collet body 1.6mm 9/20/25F/30

70067 Collet body 2.0mm 9/20/25F/30

13N28 Collet body 2.4mm 9/20/25F/30

13N29 Collet body 3.2mm 9/20/25F/30

10N30 Collet body 1.0mm 17/18/26

10N31 Collet body 1.6mm 17/18/26

70064 Collet body 2.0mm 17/18/26

10N32 Collet body 2.4mm 17/18/26

70065 Collet body 3.0mm 17/18/26

10N28 Collet body 3.2mm 17/18/26

406488 Collet body 4.0mm 17/18/26

17CB24 Collet body stubby 3,2mm 17/18/26

53N18 Collet body 1.0mm 24/24W

53N19 Collet body 1.6mm 24/24W

24CB332 Collet body 2.4mm 24/24W

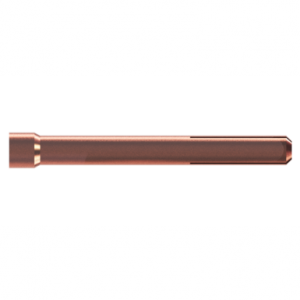

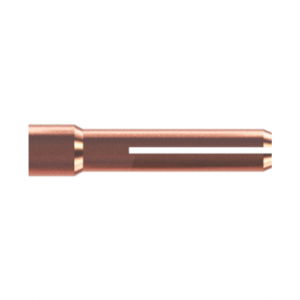

Collet 9/20/25F/30

Collet 17/18/26

Collet stubby 17/18/26

Collet HD 18SC

Collet 24/24W

Collet for gas lens 24/24W

Collet 121/301

Collet 450

Specifications

13N21 Collet 1.00mm 9/20/25F/30

13N22 Collet 1.6mm 9/20/25F/30

70066 Collet 2.0mm 9/20/25F/30

13N23 Collet 2.4mm 9/20/25F/30

13N24 Collet 3.2mm 9/20/25F/30

10N22 Collet 1.0mm 17/18/26

10N23 Collet 1.6mm 17/18/26

700N62 Collet 2.0mm 17/18/2

10N24 Collet 2.4mm 17/18/26

70063 Collet 3.0mm 17/18/26

10N25 Collet 3.2mm 17/18/26

10N25 Collet 4.0mm 17/18/26

10N23S Collet stubby 1.6mm 17/18/26

10N24S Collet stubby 2.4mm 17/18/26

10N25S Collet stubby 3.2mm 17/18/26

10N24HD Collet HD 2.4mm 18SC

10N25HD Collet HD 3.2mm 18SC

10N20HD Collet HD 4.0mm 18SC

53N16 Collet 1.0mm 24/24W

53N14 Collet 1.6mm 24/24W

24C332 Collet 2.4mm 24/24W

53N63 Collet for gas lens 1.0m 24/24W

53N64 Collet for gas lens 1.6m 24/24W

53N64s Collet for gas lens 2.4m 24/24W

0315021 Collet 1.6mm 121/301

0315022 Collet 2.4mm 121/301

0315023 Collet 3.2mm 121/301

0315024 Collet 4.0mm 121/301

0314101 Collet 1.6mm 450

0314102 Collet 2.4mm 450

0314103 Collet 3.2mm 450

0314104 Collet 4.0mm 450

0314105 Collet 4.8mm 450

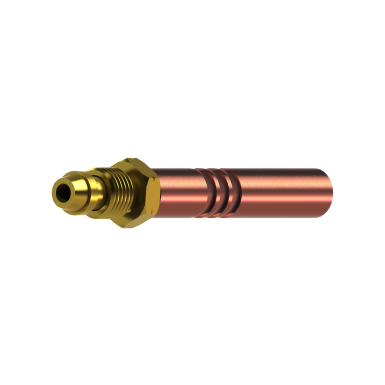

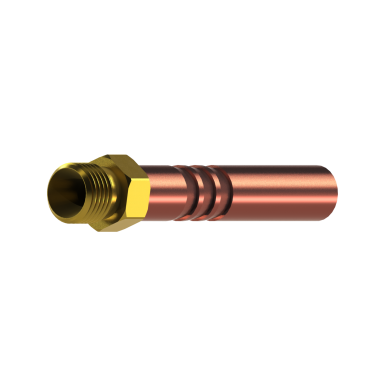

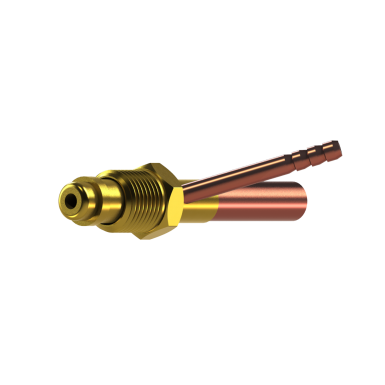

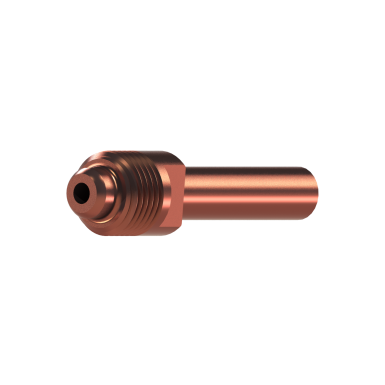

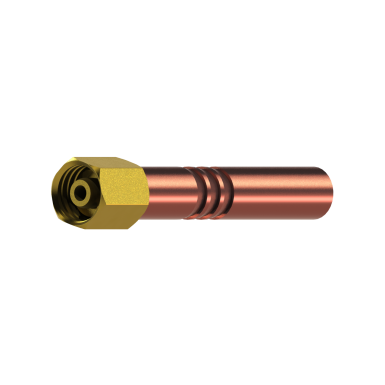

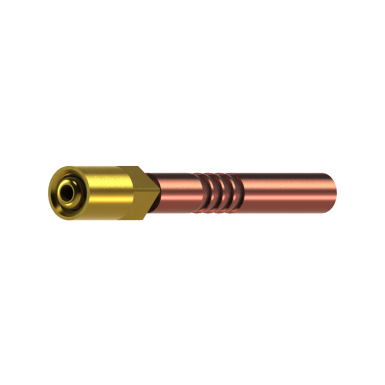

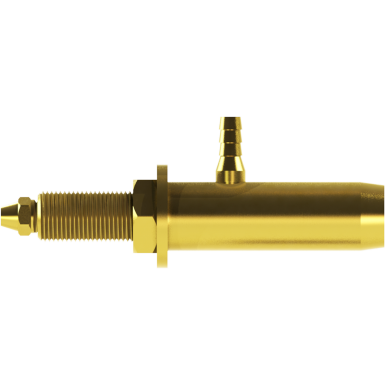

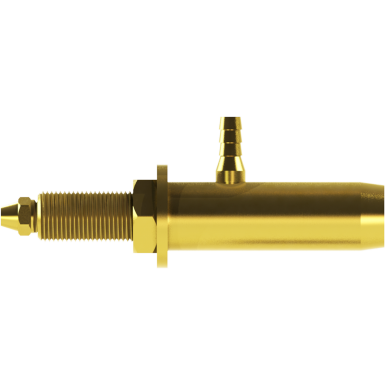

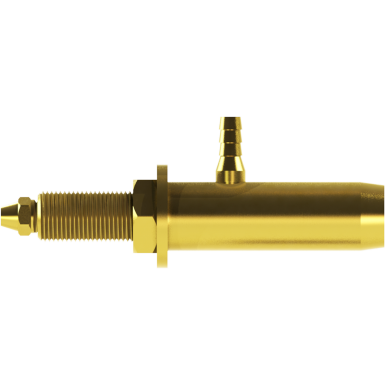

TIG-9/17/121

TIG-9/17/121

TIG-18/18C/301

TIG-20/24W/25F

TIG-24

TIG-26

TIG-26

TIG-450

Specifications

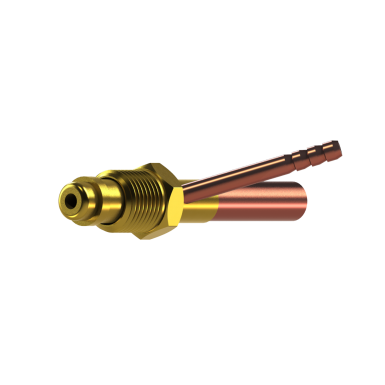

End fitting for TIG-9/17/121

End fitting for TIG-9/17/121 (separate gas- and power cable)

End fitting for TIG-18/18C/301

End fitting for TIG-20/24W/25F

End fitting for TIG-24

End fitting for TIG-26

End fitting for TIG-26 (separate gas- and power cable)

End fitting for TIG-450

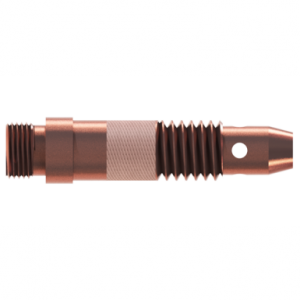

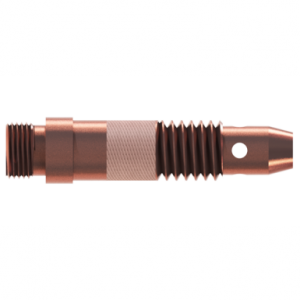

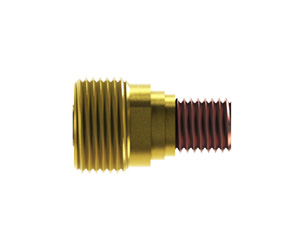

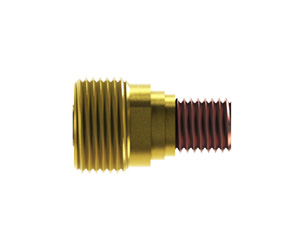

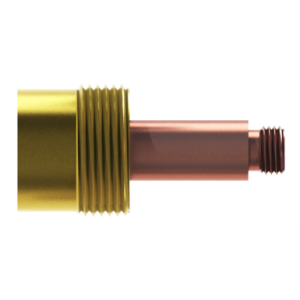

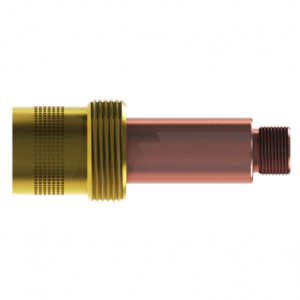

Gas lens 9/20/24/24W/25F/30

Gas lens 17/18/26

Gas lens XL 17/18/26

Gas lens 18SC

Gas lens 121/301

Specifications

45V42 Gas lens 1.0mm 9/20/24/24W/25F/30

45V43 Gas lens 1.6mm 9/20/24/24W/25F/30

70058 Gas lens 2.0mm 9/20/24/24W/25F/30

45V44 Gas lens 2.4mm 9/20/24/24W/25F/30

45V45 Gas lens 3.2mm 9/20/24/24W/25F/30

45V24 Gas lens 1.0mm 17/18/26

45V25 Gas lens 1.6mm 17/18/26

70060 Gas lens 2.0mm 17/18/26

45V26 Gas lens 2.4mm 17/18/26

70061 Gas lens 3.0mm 17/18/26

45V27 Gas lens 3.2mm 17/18/26

45V28 Gas lens 4.0mm 17/18/26

45V116 Gas lens XL 1.6mm 17/18/26

45V64 Gas lens XL 2.4mm 17/18/26

995795 Gas lens XL 3.2mm 17/18/26

45V63 Gas lens XL 4.0mm 17/18/26

18GL16 Gas lens 1.6mm 18SC

18GL32 Gas lens 2.4mm 18SC

18GL18 Gas lens 3.2mm 18SC

18GL53 Gas lens 4.0mm 18SC

0316025 Gas lens 1.6mm 121/301

0316026 Gas lens 2.4mm 121/301

0316027 Gas lens 3.2mm 121/301

0316028 Gas lens 4.0mm 121/301

Flip up welding goggles

Specifications

HC Anti-scratch

AF Anti-fog

W5 Shade 5

Safety grinding goggles

Specifications

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Indoor/Outdoor lens

Yellow

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Clear

Yellow

Grey

Specifications

Clear / Yellow / Grey lens

HC Anti-scratch

AF Anti-fog

Goggles

Clear

Specifications

Clear lens

HC Anti-scratch

AF Anti-fog

T230

Specifications

Sizes 8-11

T240

Specifications

Sizes 7-11

T268

Specifications

Sizes 8,10,11

T269

Specifications

Sizes 8-11

T275

Specifications

Sizes 8-12

T480

Specifications

Sizes 8,10

T580

Specifications

Sizes 6-11

T88

Specifications

Sizes 8-11

Extended hood and leather coverage

Specifications

Extended Hood for Welding Helmet

Extended hood made out of durable flame-retardant cotton. It is suitable for overhead welding and helps on-site and field welders be protected against burns caused be welding spatter.

Can be ordered together or separately

Characteristics:

Force 300 Automatic welding helmet

Specifications

Force 300

Force 700 Automatic welding helmet

Specifications

Force 710S

Force 730S

Force 800 Automatic welding helmet

Specifications

Force 820S:

Force 830S:

Force 900 Automatic Welding Helmet

With flip-up lens

Suitable for welding, grinding and cutting

Specifications Force 900 Welding Helmet

The automatic Force 900 welding helmet has the welder covered in every situation – welding, grinding and cutting.

ClearView

Cartridge is equipped with ClearView Technology, which provides you with an ultra-clear view during welding.

Digital Display Control

The Force 900 Digital Display Control has a clear interface design. You can switch between different modes within seconds. It also has a memory function which allows you to save the set parameters when switching between modes.

Multi-Functional Flip-UP Design

The Force 900 is a flip-up helmet with easy lift for grinding function, suiting welding/cutting/grinding mode. The transparent grinding lens is curved with a large view area of (20 x 12 cm). The welding lens with the highest optical glass -1/1/1/1- provides an exceptionally clear view of the arc during welding.

Technical Specifications Helmet

20 °C ~ +70 °C (-4 °F ~ 158 °F)

PAPR Fresh air system

Specifications

Inhaled air 50 times cleaner than air in the immediate area

TH2 approved

Comfortable to wear

Unique design

Suitable for grinding and cutting

Easy to clean head cap

AirForce Fresh air set with flip-up helmet

Specifications

P.N.: 570400

This product could be used in below field:

1- Isolating ward and medical observation site

2-Transfer of the infected

3-Corpse treatment

4-Environment disinfection

5-Sample collection

6-Laboratory testing

Ultrasonic seaming technology

Seamed with ultrasonic welding, with high-intensity feature and longer lifetime.

Multi-layer fabric

Lightweight specialized fabric. TM-H2 with a longer length to protect neck and shoulder.

Full view visual field

Large window size, curved design to better fit face-line, expanding the visual field.

Adjustable headgear

Adjustable headgear, with soft sweatband, improving the wearing comfort.

Leather apron

90 x 70 cm

Specifications

Leather apron

90 x 70 cm

Leather arm protectors (pair)

Specifications

Leather arm protectors (pair)

Leather jacket

Sizes L, XL

Specifications

Leather jacket

Sizes L, XL

Leather leg proctectors (pair)

Specifications

Leather leg proctectors (pair)

Leather pants

Size L

Specifications

Leather pants (without belt)

Size L

8XC COBOT MIG EXTRACTOR – WATER COOLED

CO2 – 550 AMP, MIXED GASES – 500 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for a longer lifetime.

Two unique nozzle designs 14mm and 17mm for optimal performance and durability

The 8XC Cobot MIG Extractor integrates the most efficient fume extraction structure in the welding industry.

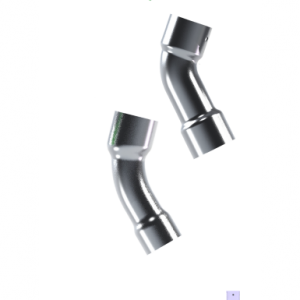

The torch comes with four different angles 22, 35°, 45° and straight. The 8XC Cobot MIG Extractor, combined

with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source.

The 8XC Cobot MIG Extractor provides the safest and most effective solution for welders and workers to

breathe CLEAN AIR and better work environments

8XC MINI Cobot 250 MIG Fume Extraction Gun – AIR COOLED

CO2 – 280 AMP, MIXED GASES – 250 AMP, DUTY CYCLE – 100%

The 8XC Cobot Fume Extractor reduces welding fume by Up To 98% and has a unique contact tip for manual fitting and durability. Moreover, This cobot fume extractor gun designs a special contact tip for a longer lifetime. Also, we created two unique nozzles, 14mm and 17mm, for optimal performance and durability.

It is designed to be one of the most efficient fume extraction systems available in the welding industry. This torch is available in four different angles: 22°, 35°, 45°, and straight. When the 8XC Cobot MIG Fume Extractor is used with the ClearO2 W-series 100 and 200, it allows for up to 98% of welding fumes to be captured directly at the fume source. As a result, this Cobot 8XR MIG Fume Extractor is one of the safest and most effective welding fume extraction solutions available to ensure the safety of welding workers and for better working environments and working with the UR10e, UR5e, & UR16e Universal Robots.

HOW DOES IT WORK?

The 8XC MIG Fume Extractor is specifically designed for use by Cobots and Semi-Automated machines. There is a special design of nozzle on the 8XC and the combination of the unique design with the ClearO2 W-series, 100 and 200, provides the most effective results in the direct extraction of fumes from the source. In addition, the nickel-plated contact tips are designed to last a longer time than the other contact tips on the market. These tips are available for use with all kinds of wires and in different sizes. The 8XC MIG Cobot fume extractor can use three types of Universal Robots: UR5e, UR10e, and UR16e.

To achieve the most outstanding results possible, the nozzle is unique in design. The openings, wall thickness, and size are all special to the nozzle. In addition, we have developed the grip ribs so that they perform optimally for optimal operation and superior performance.

CO2

Mixed Gases – 150 Amp

Duty Cycle 80%

Air Cooled

Specifications

CO2 – 180 Amp

Mixed Gases – 150 Amp

Duty Cycle 80%

Air Cooled

CO2 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

CO2 – 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 – 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

CO2 – 250 Amp

Mixed gases – 220 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 – 250 Amp

Mixed gases – 220 Amp

Duty cycle 60%

Air-cooled

CO2 – 250 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 250 Amp

Mixed gases – 200 Amp

Duty Cycle – 60%

Air-cooled

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Also available as a Microliner (ML) version

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

CO2 – 350 Amp

Mixed gases – 320 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 350 Amp

Mixed gases – 320 Amp

Duty cycle – 60%

Air-cooled

CO2 – 400 Amp

Mixed gases – 380 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 400 Amp

Mixed gases – 380 Amp

Duty cycle – 60%

Air-cooled

CO2

Mixed Gases – 150 Amp

Duty Cycle 80%

Air Cooled

Specifications

CO2 – 180 Amp

Mixed Gases – 150 Amp

Duty Cycle 80%

Air Cooled

CO2 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

CO2 – 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 – 180 Amp

Mixed gases 150 Amp

Duty cycle 60%

Air-cooled

CO2 – 250 Amp

Mixed gases – 220 Amp

Duty cycle 60%

Air-cooled

Specifications

CO2 – 250 Amp

Mixed gases – 220 Amp

Duty cycle 60%

Air-cooled

CO2 – 300 Amp

Mixed gases – 270 Amp

Duty cycle – 60%

Water-cooled

Specifications

CO2 – 300 Amp

Mixed gases – 270 Amp

Duty cycle – 60%

Water-cooled

CO2 – 250 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 250 Amp

Mixed gases – 200 Amp

Duty Cycle – 60%

Air-cooled

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 230 Amp

Mixed gases – 200 Amp

Duty cycle – 60%

Air-cooled

CO2 – 360 Amp

Mixed gases – 340 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 360 Amp

Mixed gases – 340 Amp

Duty cycle – 100%

Water-cooled

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Also available as a Microliner (ML) version

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 320 Amp

Mixed gases – 300 Amp

Duty cycle – 60%

Air-cooled

CO2 – 350 Amp

Mixed gases – 320 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 350 Amp

Mixed gases – 320 Amp

Duty cycle – 60%

Air-cooled

CO2 – 400 Amp

Mixed gases – 380 Amp

Duty cycle – 60%

Air-cooled

Specifications

CO2 – 400 Amp

Mixed gases – 380 Amp

Duty cycle – 60%

Air-cooled

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cyle

Water – cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cyle

Water – cooled

Also available as a Microliner (ML) version

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

CO2 – 300 Amp

Mixed gases – 270 Amp

Duty cycle – 60%

Water-cooled

Specifications

CO2 – 300 Amp

Mixed gases – 270 Amp

Duty cycle – 60%

Water-cooled

CO2 – 360 Amp

Mixed gases – 340 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 360 Amp

Mixed gases – 340 Amp

Duty cycle – 100%

Water-cooled

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

Specifications

CO2 – 500 Amp

Mixed gases – 450 Amp

Duty cycle – 100%

Water-cooled

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cyle

Water – cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cyle

Water – cooled

Also available as a Microliner (ML) version

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

Specifications

CO2 – 550 Amp

Mixed gases – 500 Amp

100% Duty cycle

Water-cooled

Also available as a Microliner (ML) version

One button switch

Two button switch

Potentiometer

Digital display

Specifications

8M8901 8XM Module One button switch (1B)

8M8902 8XM Module Two button switch (2B)

8M8910 8XM Module Potentiometer (10K)

306535 Quick Connect switch cable 3mtr

306536 Quick Connect switch cable 4mtr

306537 Quick Connect switch cable 5mtr

306559 Switch cable end without plug (Quick Connect)

306545 Locking clip (Quick Connect)

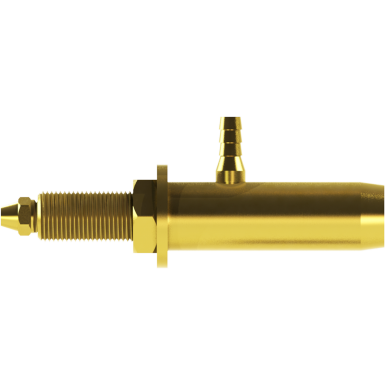

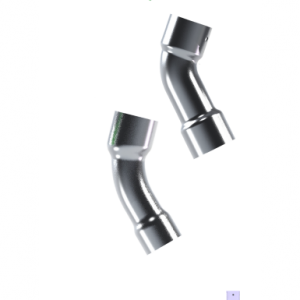

Connection kit suitable for Fronius

Connection kit suitable for Cloos

Direct connection – standard

Direct connection – T-piece

Specifications

Connection kit suitable for Fronius – Air cooled

Connection kit suitable for Fronius – Water cooled

Connection kit suitable for Cloos – Air cooled

Connection kit suitable for Cloos – Water cooled

Direct connection – standard

Direct connection – T-piece

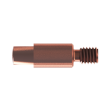

M6-06-0,6mm

M6-06-1,0mm for Alu wire

M6-06-0,6mm nickel plated

Specifications

M6-06-0,6mm

M6-06-0,8mm

M6-06-0,9mm

M6-06-1,0mm

M6-06-1,2mm

M6-06-0,8mm for Alu wire

M6-06-1,0mm for Alu wire

M6-06-1,2mm for Alu wire

M6-06-0,6mm Nickel plated

M6-06-0,8mm Nickel plated

M6-06-1,0mm Nickel plated

Contact tip M6-08-0,6mm

Contact tip M6-08-0,8mm for Alu wire

Contact tip M6-08-0,8mm CuCrZr

Contact tip M6-08-0,6mm Nickel plated

Specifications

Contact tip M6-08-0,6mm

Contact tip M6-08-0,8mm

Contact tip M6-08-0,9mm

Contact tip M6-08-1,0mm

Contact tip M6-08-1,2mm

Contact tip M6-08-1,4mm

Contact tip M6-08-1,6mm

Contact tip M6-08-0,8mm for Alu wire

Contact tip M6-08-1,0mm for Alu wire

Contact tip M6-08-1,2mm for Alu wire

Contact tip M6-08-1,6mm for Alu wire

Contact tip M6-08-0,8mm CuCrZr

Contact tip M6-08-1,0mm CuCrZr

Contact tip M6-08-1,2mm CuCrZr

Contact tip M6-08-1,4mm CuCrZr

Contact tip M6-08-1,6mm CuCrZr

Contact tip M6-08-0,6mm Nickel plated

Contact tip M6-08-0,8mm Nickel plated

Contact tip M6-08-1,0mm Nickel plated

Contact tip M6-08-1,2mm Nickel plated

Contact tip M8-100-0,8mm

Contact tip M8-100-0,8mm for Alu wire

Contact tip M8-100-0,8mm CuCrZr

Contact tip M8-100-0,8mm Nickel plated

Specifications

Contact tip M8-100-0,8mm

Contact tip M8-100-0,9mm

Contact tip M8-100-1,0mm

Contact tipM8-100-1,2mm

Contact tip M8-100-1,4mm

Contact tip M8-100-1,6mm

Contact tip M8-100-2,0mm

Contact tipM8-100-2,4mm

Contact tip M8-100-0,8mm for Alu wire

Contact tip M8-100-1,0mm for Alu wire

Contact tip M8-100-1,2mm for Alu wire

Contact tip M8-100-1,6mm for Alu wire

Contact tip M8-100-0,8mm CuCrZr

Contact tip M8-100-1,0mm CuCrZr

Contact tip M8-100-1,2mm CuCrZr

Contact tip M8-100-1,4mm CuCrZr

Contact tip M8-100-1,6mm CuCrZr

Contact tip M8-100-0,8mm Nickel plated

Contact tip M8-100-1,0mm Nickel plated

Contact tip M8-100-1,2mm Nickel plated

Contact tip M8-100-1,4mm Nickel plated

Universal adapter and Lincoln tail

Fits all Translas standard MIG torches

Specifications

Universal adapter and Lincoln tail

Fits all Translas standard MIG torches

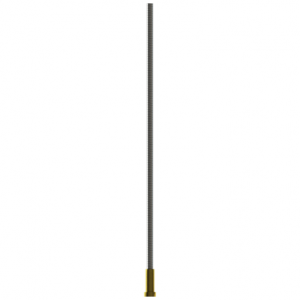

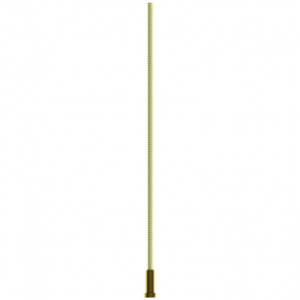

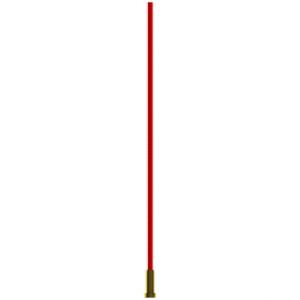

blue/ red / yellow / plain

3 mtr , 4 mtr , 5 mtr and per mtr

Specifications

Blue liner (1.5/4.5) 3mtr

Blue liner (1.5/4.5) 4mtr

Blue liner (1.5/4.5) 5mtr

Blue liner (1.5/4.5) p/mtr

Red liner (2.0/4.5) 3mtr

Red liner (2.0/4.5) 4mtr

Red liner (2.0/4.5) 5mtr

Red liner (2.0/4.5) p/mtr

Yellow liner (2.5/4.5) 3mtr

Yellow liner (2.5/4.5) 4mtr

Yellow liner (2.5/4.5) 5mtr

Yellow liner (2.5/4.5) p/mtr

Plain liner (2.0/4.0) 3mtr

Plain liner (2.0/4.0) 4mtr

Plain liner (2.0/4.0) 5mtr

Plain liner (2.0/4.0) p/mtr

Plain liner (2.0/4.5) 3mtr

Plain liner (2.0/4.5) 4mtr

Plain liner (2.0/4.5) 5mtr

Plain liner (2.0/4.5) p/mtr

Plain liner (2.5/4.0) 3mtr

Plain liner (2.5/4.0) 4mtr

Plain liner (2.5/4.0) 5mtr

Plain liner (2.5/4.0) p/mtr

Plain liner (2.5/4.5) 3mtr

Plain liner (2.5/4.5) 4mtr

Plain liner (2.5/4.5) 5mtr

Plain liner (2.5/4.5) p/mtr

Blue liner Teflon (1.5/4.0) 3mtr

Blue liner Teflon (1.5/4.0) 4mtr

Blue liner Teflon (1.5/4.0) 5mtr

Blue liner Teflon (1.5/4.0) p/mtr

Red liner Teflon (2.0/4.0) 3mtr

Red liner Teflon (2.0/4.0) 4mtr

Red liner Teflon (2.0/4.0) 5mtr

Red liner Teflon (2.0/4.0) p/mtr

Yellow liner Teflon (2.7/4.7) 3mtr

Yellow liner Teflon (2.7/4.7) 4mtr

Yellow liner Teflon (2.7/4.7) 5mtr

Yellow liner Teflon (2.7/4.7) p/mtr

Black liner Teflon (1.5/4.0) p/mtr

Black liner Teflon (2.0/4.0) p/mtr

Black liner Teflon (2.7/4.7) p/mtr

Black liner Graphite (2.0/4.0) p/mtr

Black liner Graphite (2.3/4.7) p/mtr

Black liner Graphite (2.9/4.7) p/mtr

Collet for teflon liner 4.0mm

Collet for teflon liner 4.7mm

O-ring for teflon liner 4×1,5mm

Brass wire for graphite liner 4,0mm

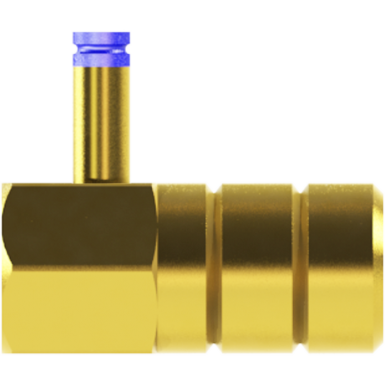

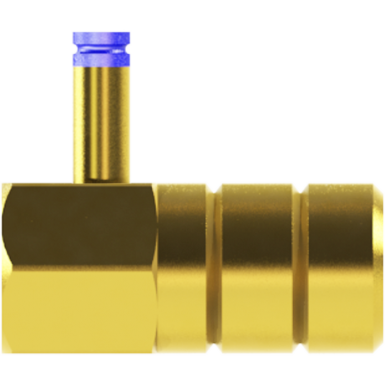

CC complete

Quick connector machine side

Quick connector male

Quick connector female

Specifications

CA complete – type 502 (Guide tube L=91mm – M10x1)

CA complete – type 506 (Guide tube L=102mm – M12x1)

CA complete – type 530 (Guide tube L=120mm – ø16mm – ø12mm)

Quick connector machine side with 6mm nipple

Quick connector machine side with 8mm nipple

Quick connector 1/8’G male

Quick connector 1/4’G male

Quick connector 3/8’G male

Quick connector with M12x1 female nut

Quick connector with 1/4’G female nut

Quick connector with 3/8’G female nut

Universal adapter and Miller tail

Fits all Translas standard MIG torches

Specifications

Universal adapter and Miller tail

Fits all Translas standard MIG torches

TR-15

TR-24

TR-25

TR-36

TR-401/501

TR-401/401 Heavy Duty

7XM-450

7XM-550/560

Specifications

TR-15 Nozzle cylindrical ø 16,1mm

TR-15 Nozzle conical ø 12mm

TR-15 Nozzle tapered ø 10,5mm

TR-15 Nozzle bottleneck ø 13mm

TR-24 Nozzle cylindrical ø 17,1mm

TR-24 Nozzle conical ø 12,5mm

TR-24 Nozzle tapered ø 10mm

TR-25 Nozzle cylindrical ø 18mm

TR-25 Nozzle conical ø 15mm

TR-25 Nozzle tapered ø 12mm

TR-25 Nozzle bottleneck ø 14mm

TR-36 Nozzle cylindrical ø 20,1mm

TR-36 Nozzle conical ø 16mm

TR-36 Nozzle tapered ø 14mm

TR-401/501 Nozzle cylindrical ø 20,1mm

TR-401/501 Nozzle conical ø 16mm

TR-401/501 Nozzle tapered ø 14mm

TR-401/501 Nozzle bottleneck ø 15,1mm

TR-401/501 Nozzle cylindrical Heavy Duty ø 19,1mm

TR-401/501 Nozzle conical Heavy Duty ø 16mm

TR-450 Nozzle cylindrical ø 14,5mm

TR-450 Nozzle conical ø 14,5mm

TR-550/560 Nozzle cylindrical ø 17mm

TR-550/560 Nozzle conical ø 17mm

Universal adapter and Tweco tail

Fits all Translas standard MIG torches

Specifications

Universal adapter and Tweco tail

Fits all Translas standard MIG torches

Spare parts suitable for ESAB torches

Spare parts suitable for FRONIUS torches

Spare parts suitable for KEMPPI torches

Air flow meter Extractor

Gas flow meter Extractor

Brush

Multitool

Ceramic spray

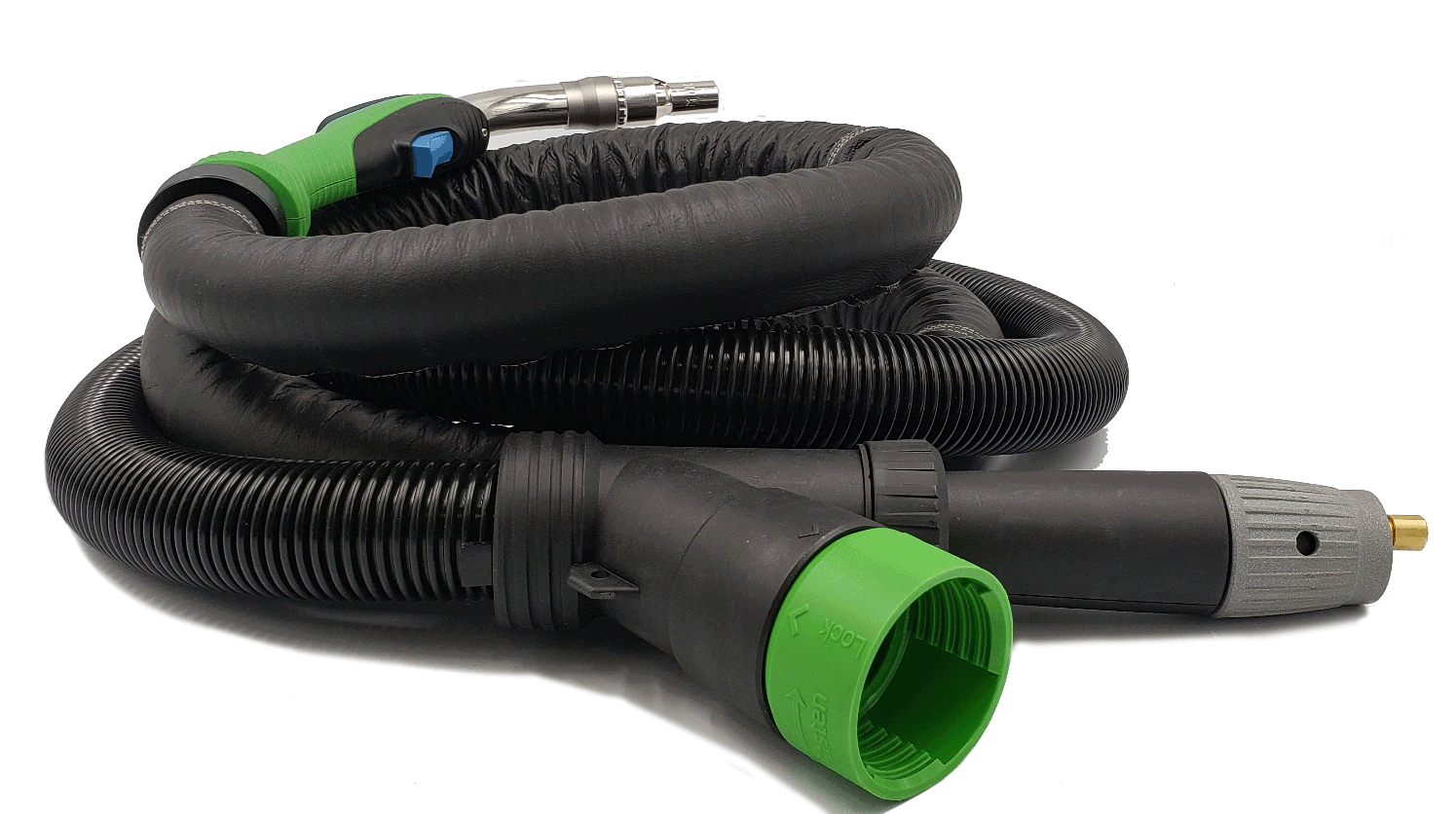

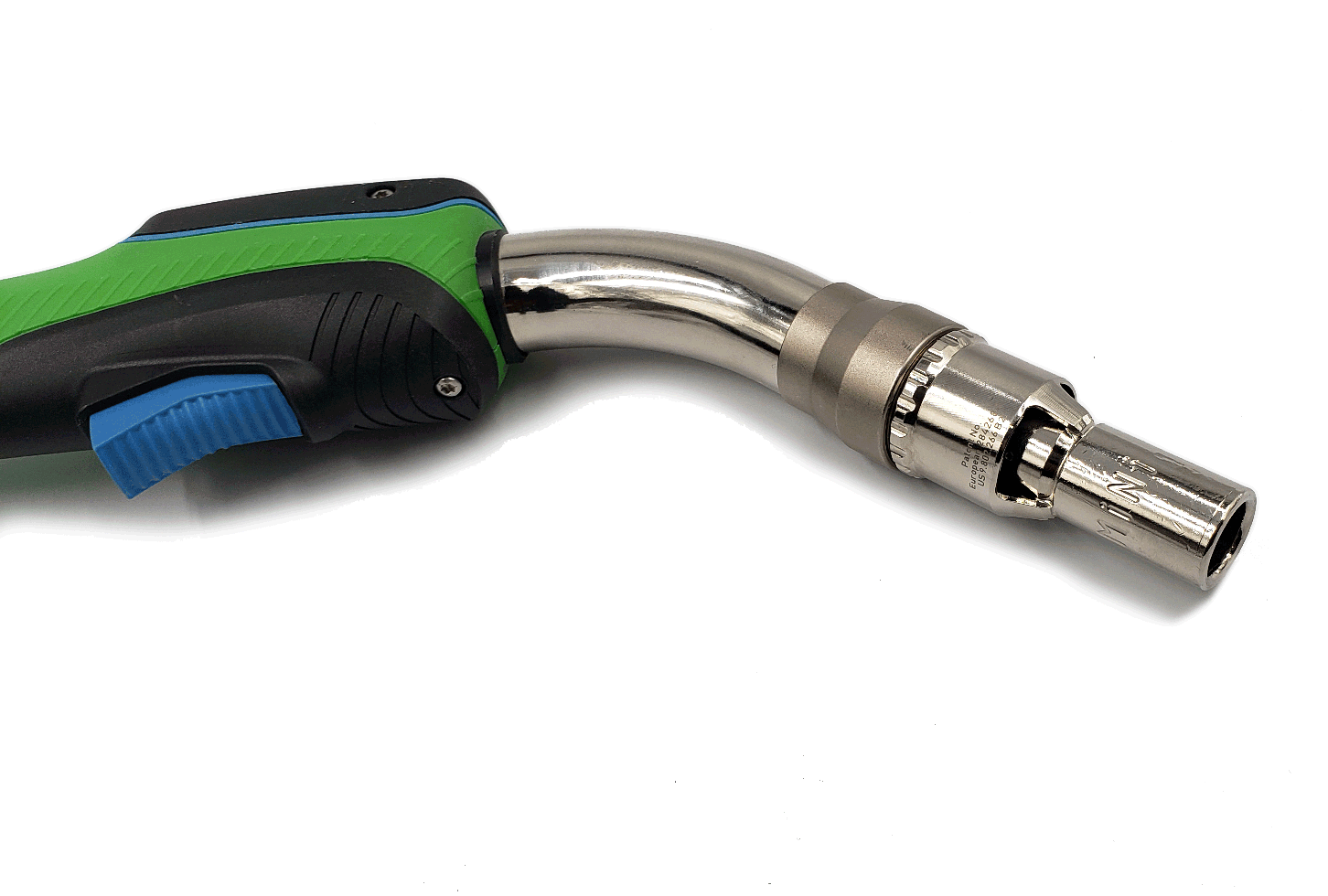

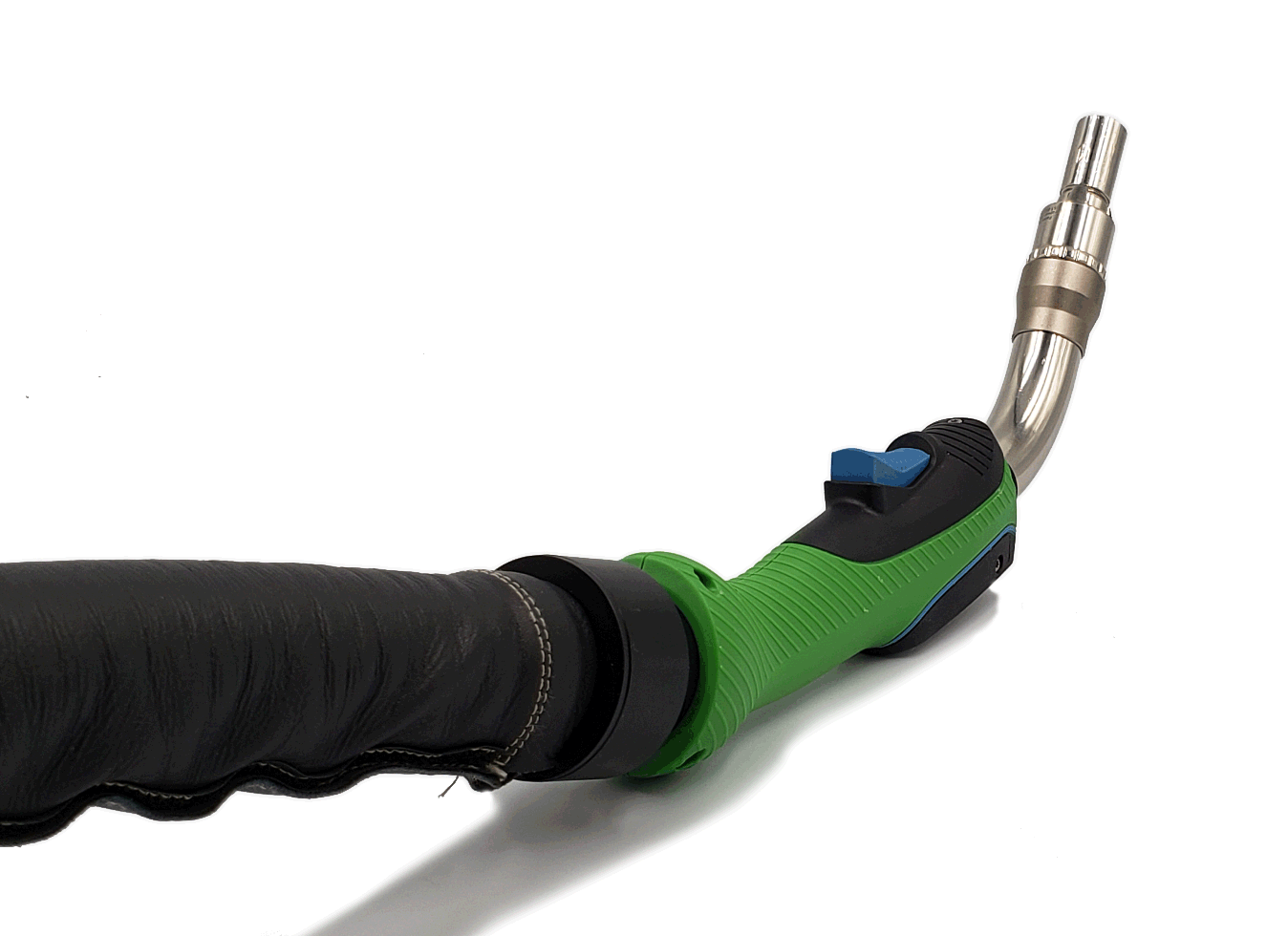

Fume extraction torch

Light weight – only 1,1 kg

CO2 – 280 Amp

250 Amp Mixed gases

100% Duty cycle

Air cooled

Specifications

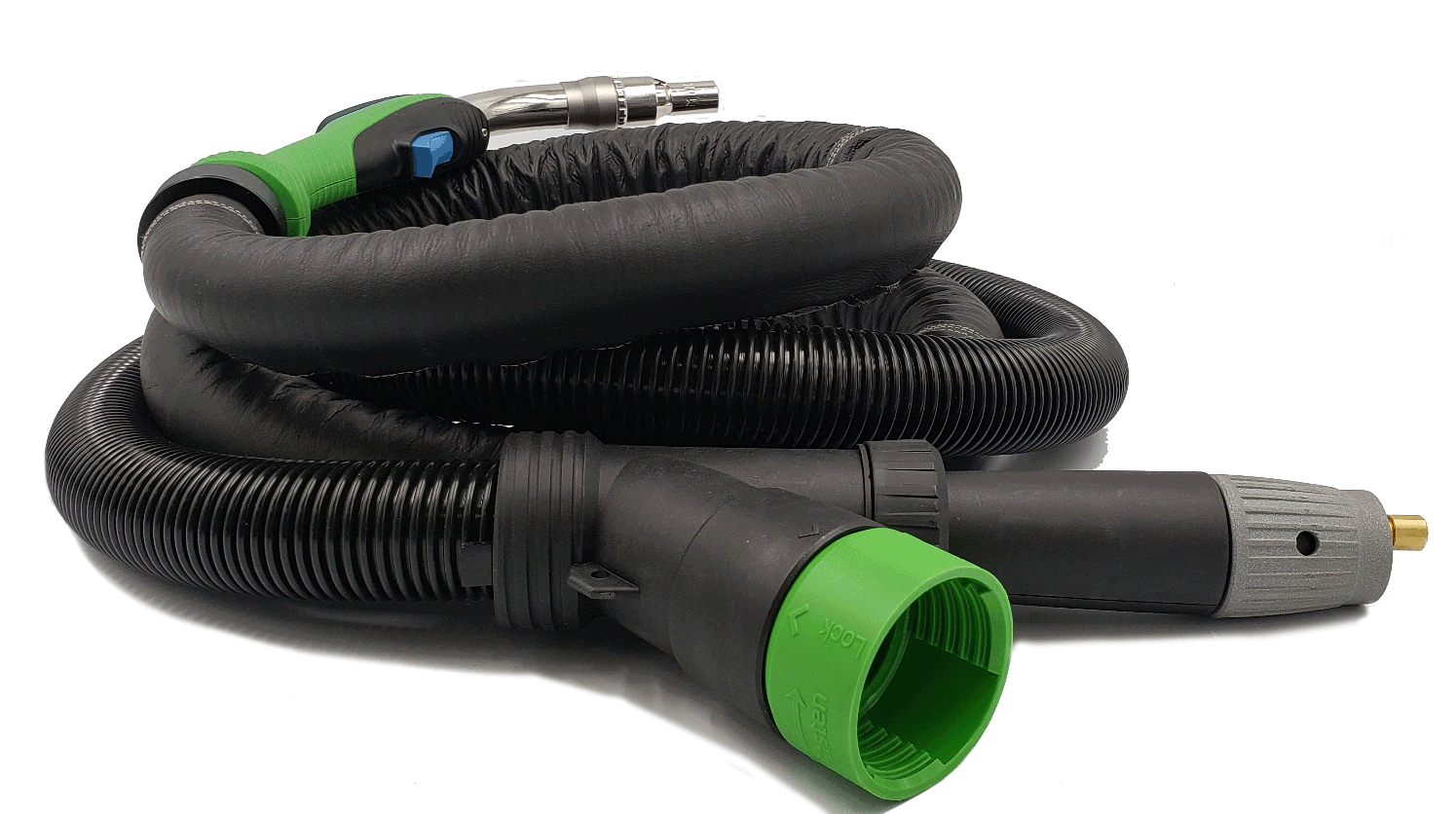

Fume extraction welding torch gun with flexible hose

CO2 – 320 Amp

300 Amp Mixed gases

100% Duty cycle

Air cooled

Specifications

Fume extraction welding torch gun with flexible hose

CO2 – 550 Amp

500 Amp Mixed gases

100% Duty Cycle

Water cooled

Specifications

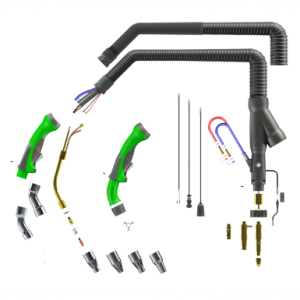

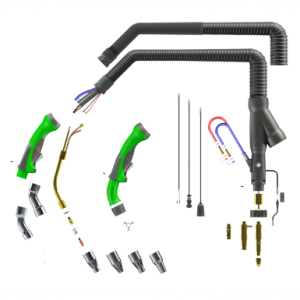

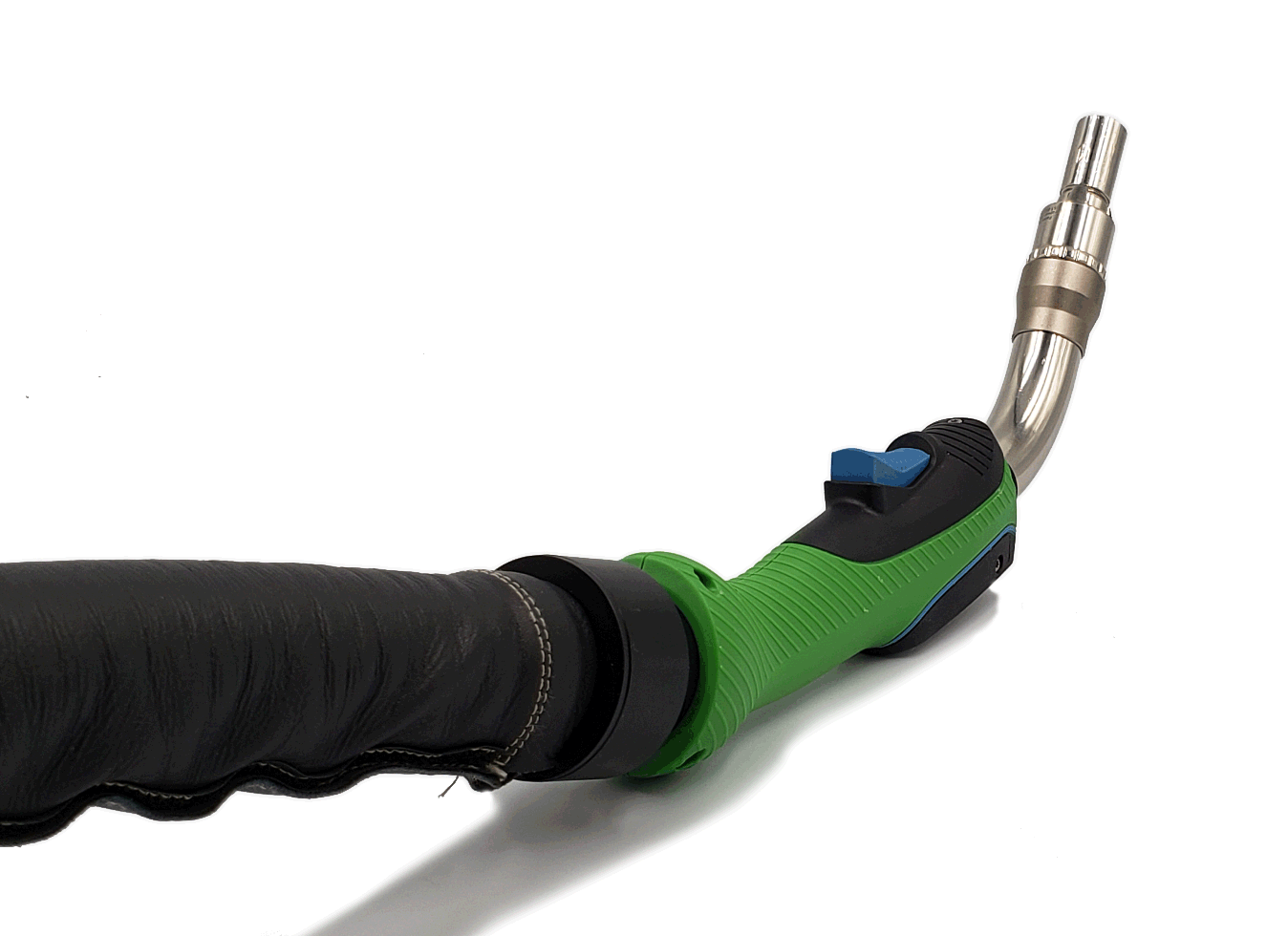

8TE TIG EXTRACTOR – 17 – Air COOLED

DC – 140 AMP, AC/DC – 100 AMP, DUTY CYCLE – 35%

Specifications:

Reduces Welding Fume Up To 95%.

Same convenient handle as regular 8XT gun.

Various switch modules are available.

Extreme Flexible hose on the first meter.

Standard TIG consumables.

The 8TE TIG Extractors protect the welders and other workers in the factory from harmful fumes

and metals like Aluminium, Chromium, Iron, Manganese, and Nickel which are possibly released during the welding process.

8TE TIG EXTRACTOR – 30 – Water COOLED

DC – 320 AMP, AC/DC – 330 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 95%.

Same convenient handle as regular 8XT gun.

Various switch modules are available.

Extreme Flexible hose on the first meter.

Standard TIG consumables.

The 8TE TIG Extractors protect the welders and other workers in the factory from harmful fumes

and metals like Aluminium, Chromium, Iron, Manganese, and Nickel which are possibly released during the welding process.

8XE MINI MIG EXTRACTOR – AIR COOLED

CO2 – 280 AMP, MIXED GASES – 250 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle design 12mm and 14mm for optimal performance and durability

The 8XE MIG Extractor integrates the most efficient fume extraction structure in the welding industry.

The torch comes with three different angles, 30°, 45° and straight. The 8XE MIG Extractor, combined

with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source.

The 8XE MIG Extractor provides the safest and most effective solution for welders and workers to

breathe CLEAN AIR and better work environments

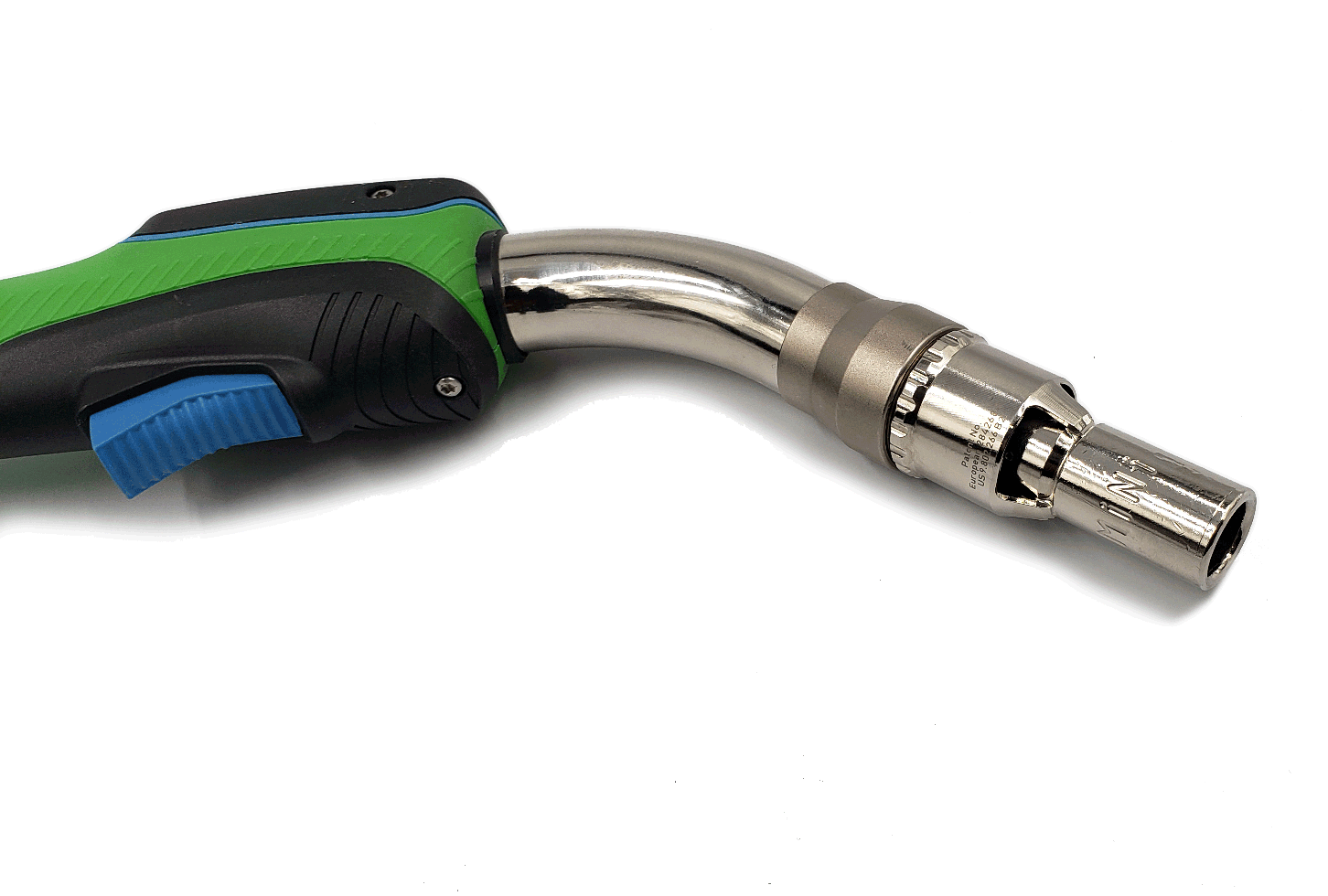

8XE MIG EXTRACTOR – AIR COOLED

CO2 – 320 AMP, MIXED GASES – 300 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle design 14mm and 17mm for optimal performance and durability

The 8XE MIG Extractor integrates the most efficient fume extraction structure in the welding industry.

The torch comes with three different angles, 30°, 45° and straight. The 8XE MIG Extractor, combined

with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source.

The 8XE MIG Extractor provides the safest and most effective solution for welders and workers to

breathe CLEAN AIR and better work environments

8XE MIG EXTRACTOR – Water COOLED

CO2 – 500 AMP, MIXED GASES – 500 AMP, DUTY CYCLE – 100%

Specifications:

Reduces Welding Fume Up To 98%

Unique contact tip for manual fitting and durability.

Special design contact tip for longer lifetime.

Ergonomic ball socket 30° angle and 360° rotatable.

Two unique nozzle design 14mm and 17mm for optimal performance and durability

The 8XE MIG Extractor integrates the most efficient fume extraction structure in the welding industry.

The torch comes with three different angles, 30°, 45° and straight. The 8XE MIG Extractor, combined

with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source.

The 8XE MIG Extractor provides the safest and most effective solution for welders and workers to

breathe CLEAN AIR and better work environments

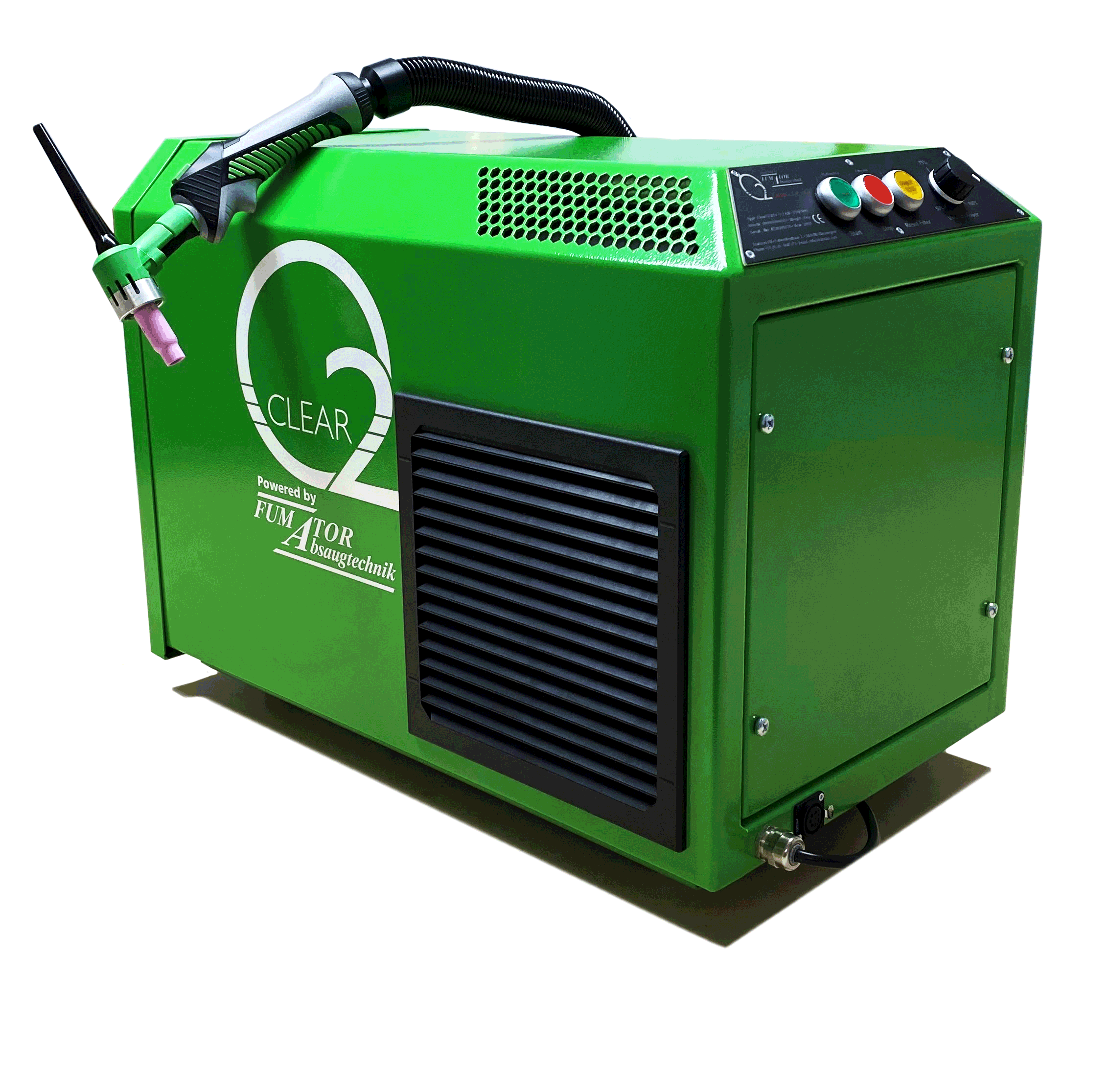

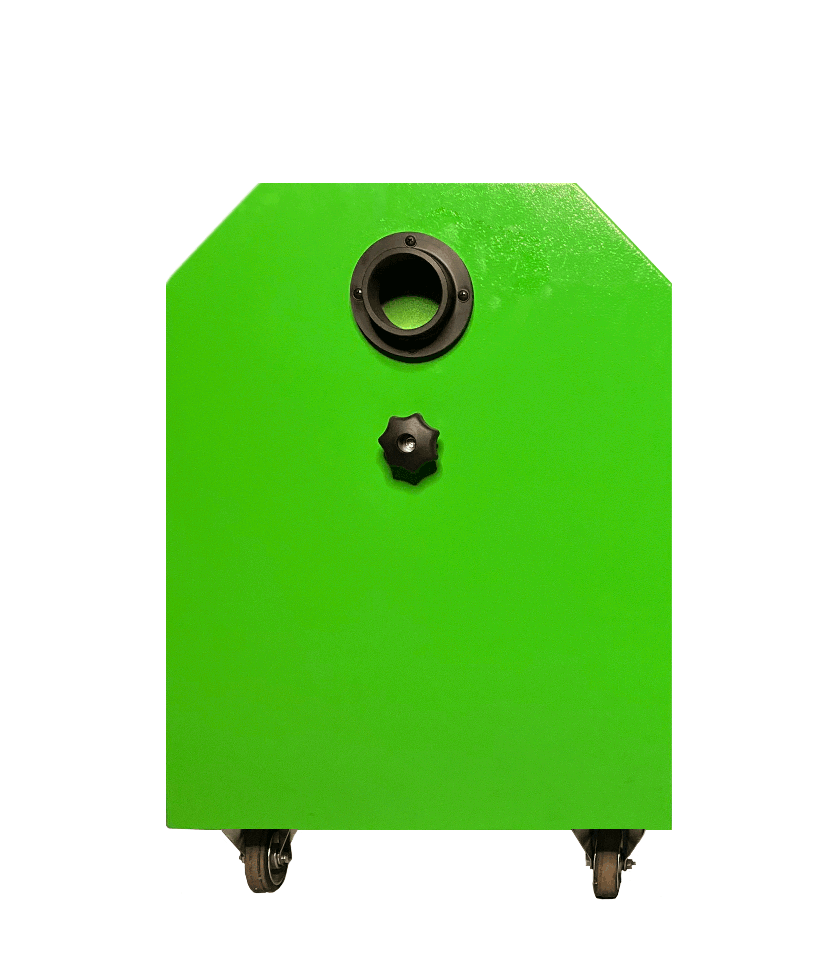

The ClearO2 T100 unit is available with a power supply of 220V-240V (T100) and CSA and CE certified. W3 Under construction.

Specifications

The ClearO2 T100 is designed to accompany the 8TE TIG Extractor from Translas. With the combination of the 8TE TIG Extractor range of welding fume torch and ClearO2 T100 unit we capture between 90% and 95% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 30 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 T100 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic Start/Stop function to preserve energy and to synchronize the unit with the 8TE TIG Extractor is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder option, the machine automatically starts working.

Light and Mobile

The ClearO2 T100 unit is designed to serve the needs of a single welder, who needs to change their work-place.

The ClearO2 unit is available with a power supply of 220V-240V (T200) and CE and W3 certified.

Specifications

The ClearO2 T200 is designed to accompany the 8TE TIG Extractor from Translas. With the combination of the 8TE TIG Extractors range of welding fume torches and ClearO2 T200 unit we capture between 90% and 95% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 45 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 T200 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. The automatic Start/Stop function to preserve energy and to synchronize the unit with the 8TE TIG Extractor is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder option, the machine automatically starts working.

Continuous rated motor

The electric motor of the unit is designed to work continuously without losing its power. Due to the automatic cleaning function and the simplified motor system, the maintenance of the unit is minimal, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light and Mobile

The ClearO2 T200 unit is designed to serve the needs of two welders, who need to change their work-place. Examples for such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 45kg – let the welder move the unit with ease to the next working location.

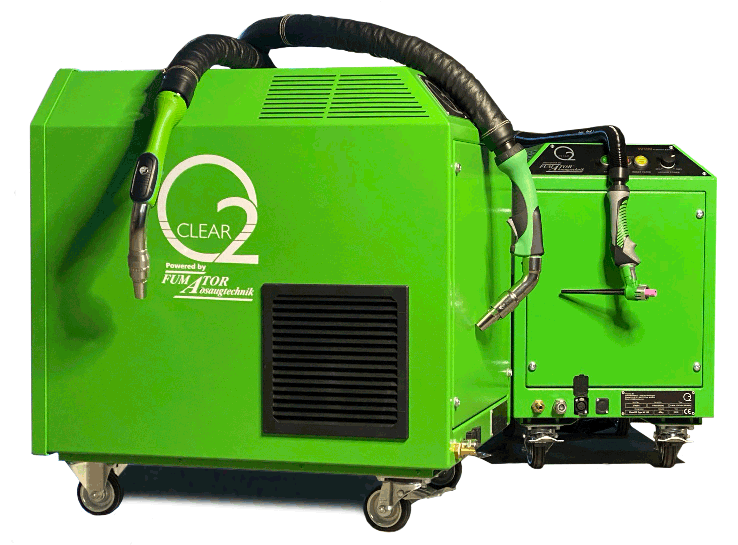

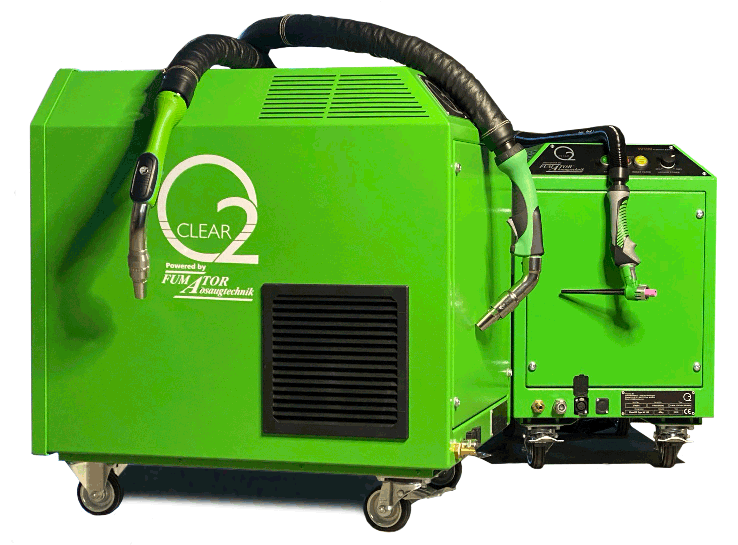

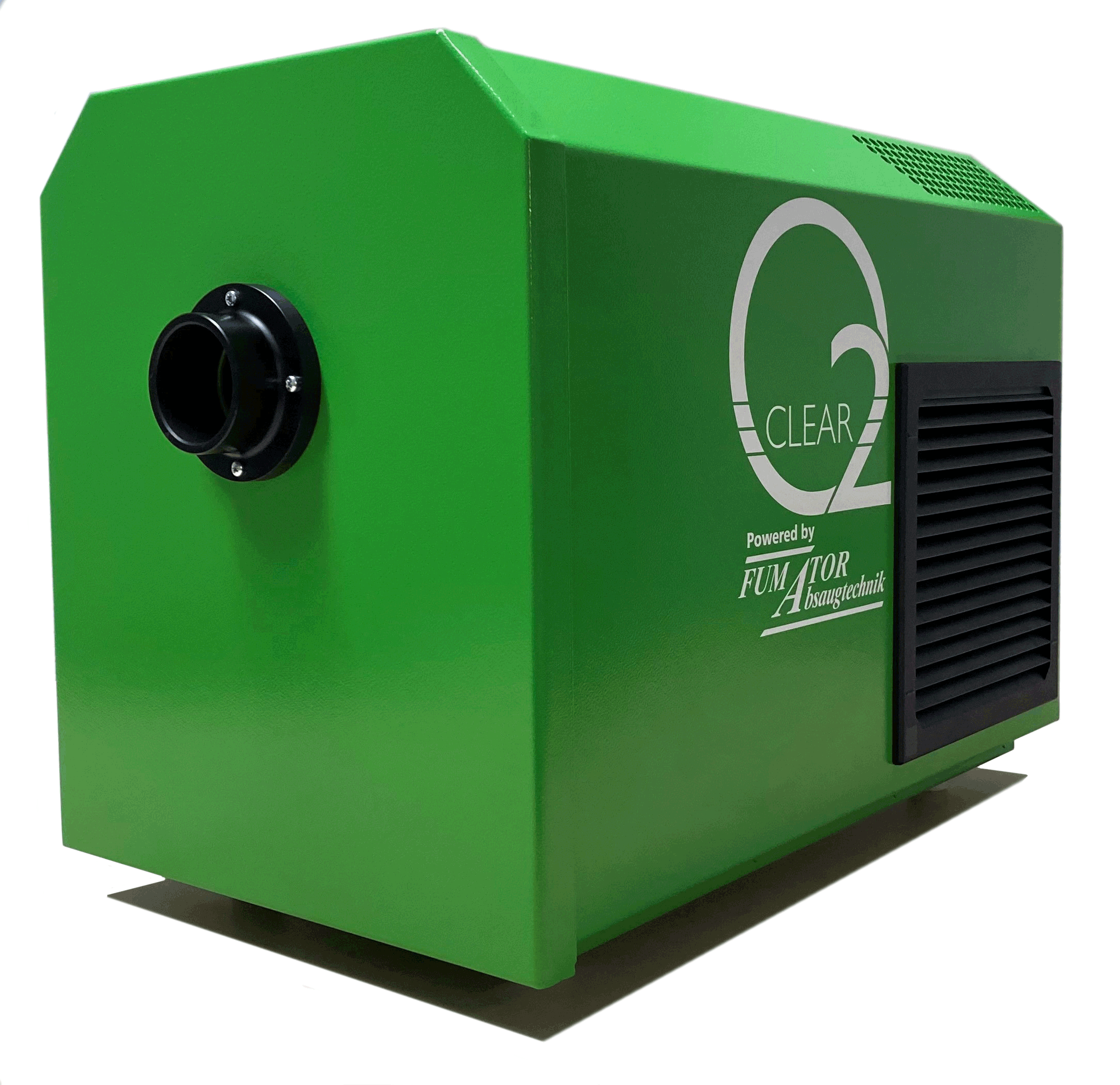

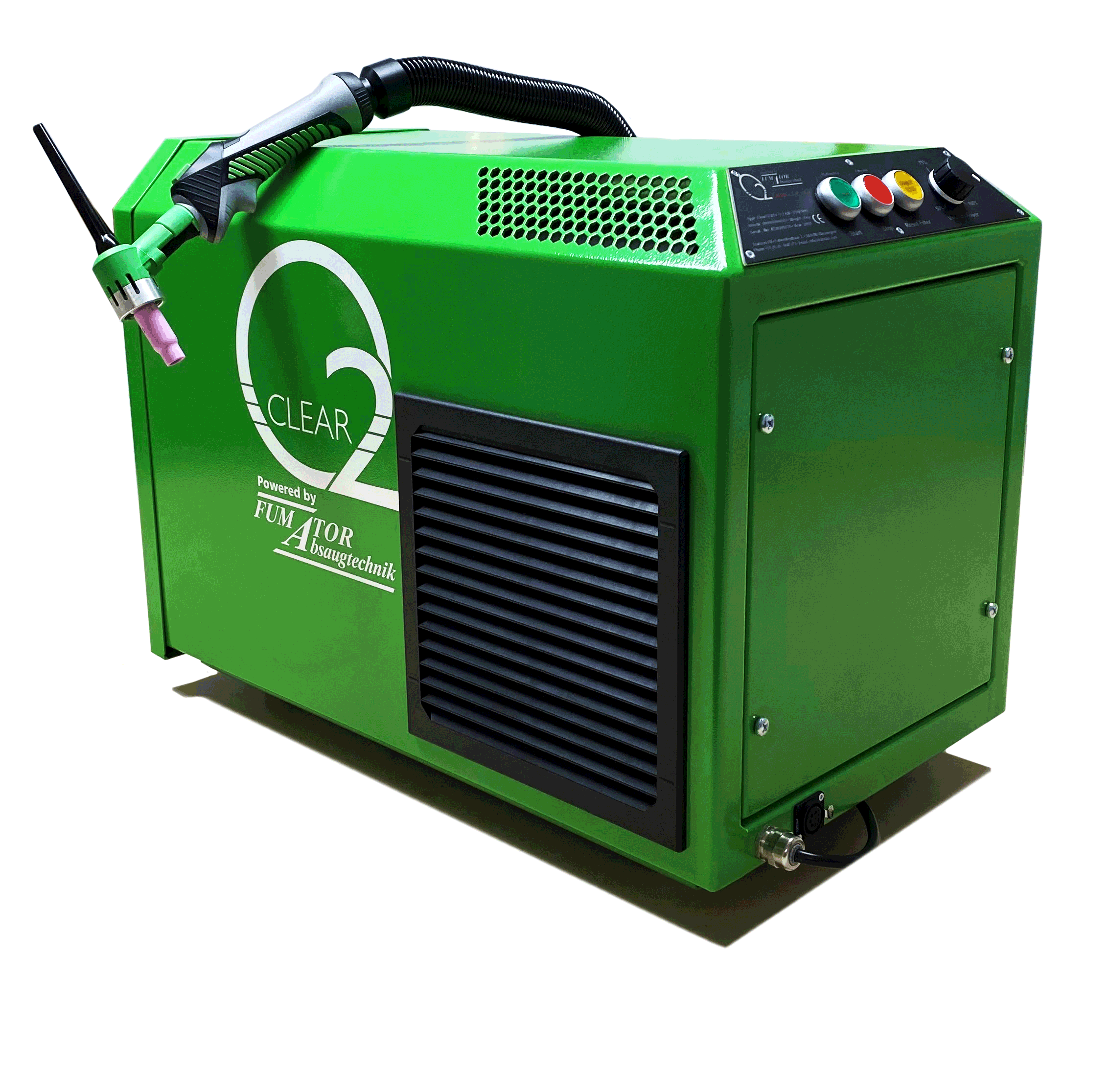

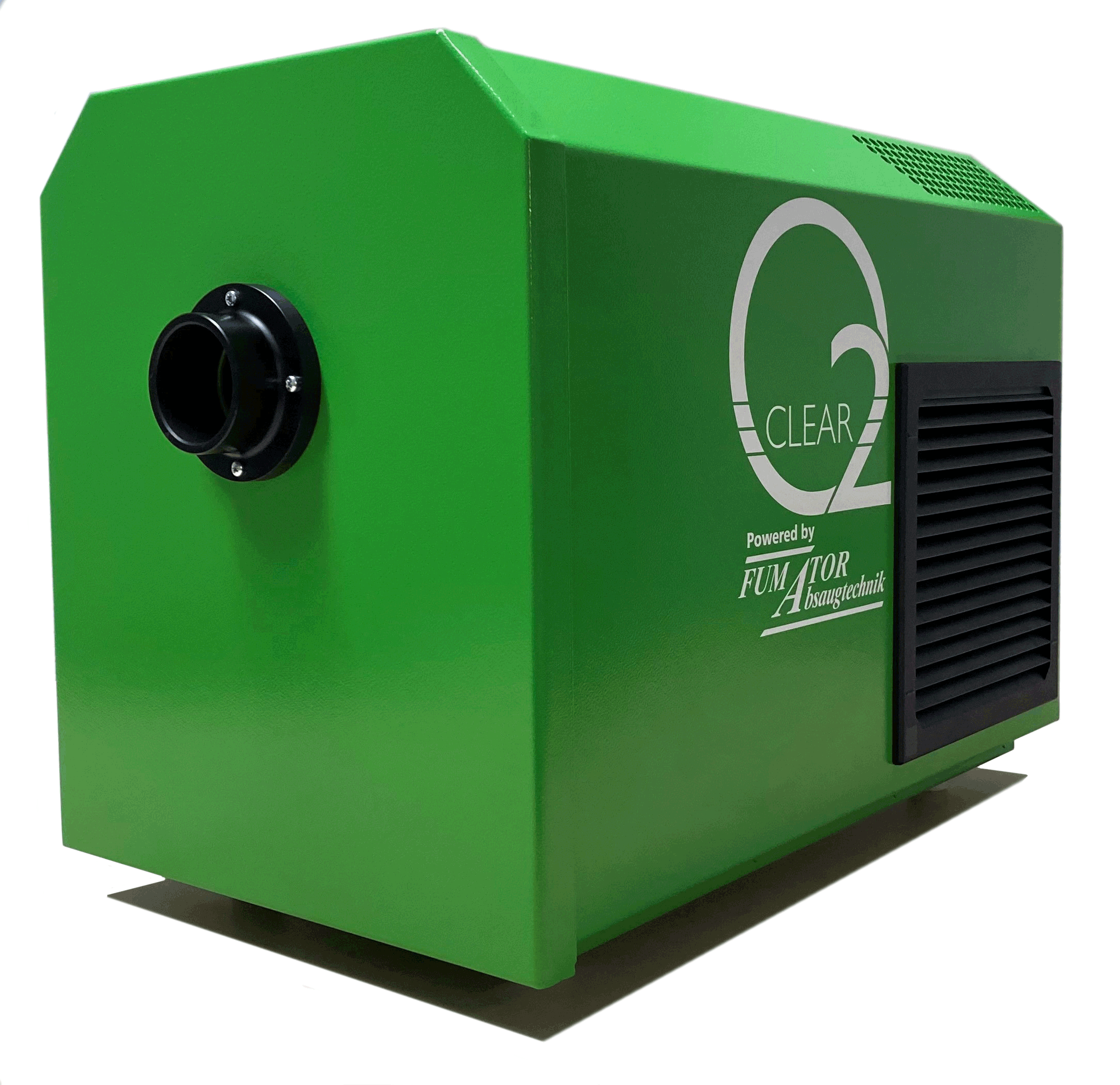

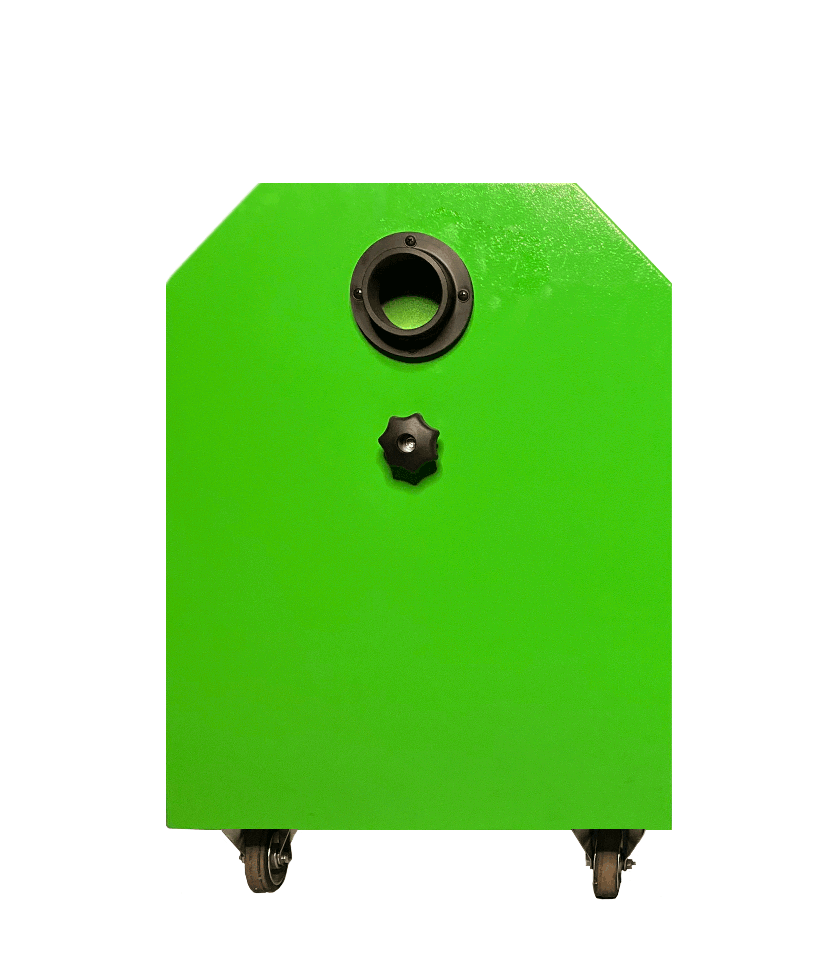

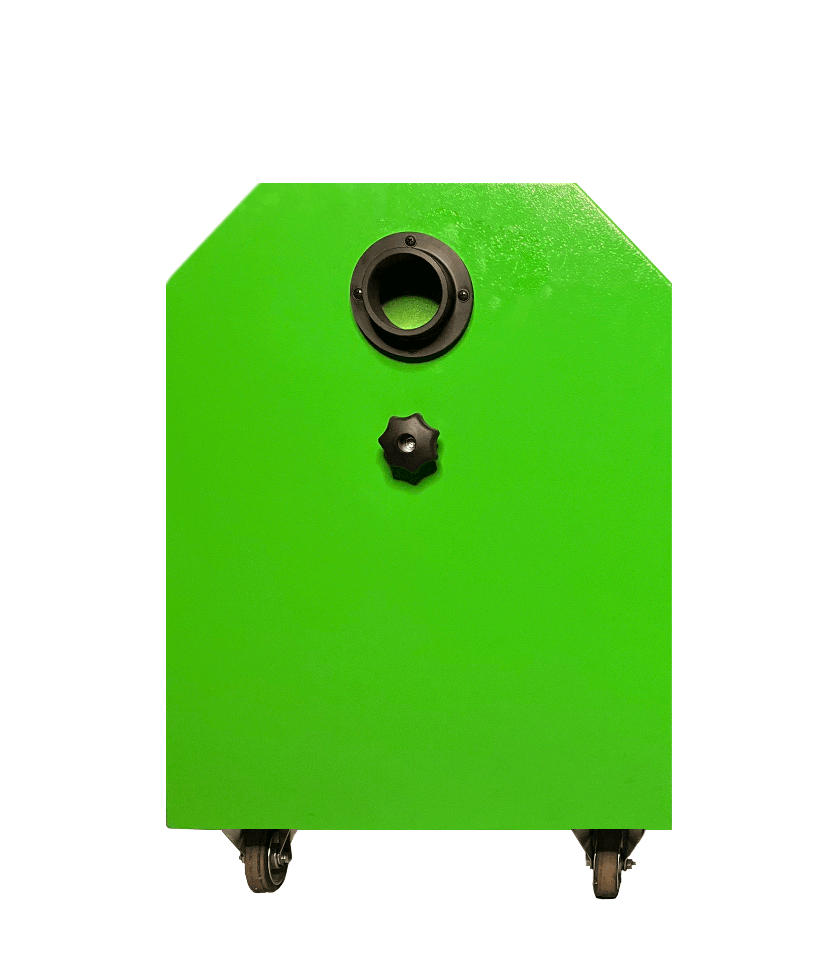

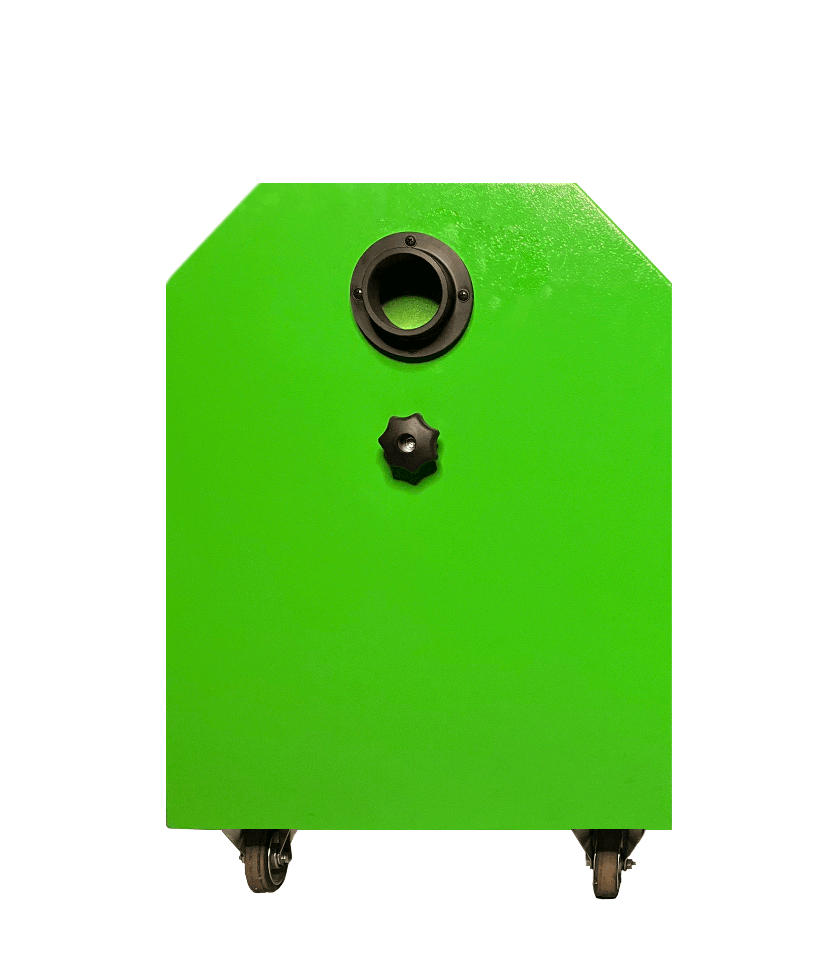

The ClearO2 unit is available with a power supply of 220V-240V (W100) or 380-480V (W150) and CE and W3 certified.

Specifications

The ClearO2 W100/ W150 is designed to accompany the 8XE MIG and 7XE MIG Extractors from Translas. With the combination of the 8XE MIG and 7XE MIG Extractors range of welding fume torches and ClearO2 W100/150 units we capture between 90% and 98% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 45 kg – and its four wheels with two lockable.

Automatic Cleaning

The ClearO2 W100/ W150 unit has an automatic cleaning function by reverse compressed air pulse. The moment the under pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. Automatic Start/Stop function to preserve energy and to synchronize the unit with the 8XE MIG and 7XE MIG Extractors is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder option, the machine automatically starts working.

Continuous rated motor

The electric motor of the unit is designed to work continuously without losing its power. Due to the automatic cleaning function and the simplified motor system, the maintenance of the unit is minimal, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light and Mobile

The ClearO2 W100/ W150 units are designed to serve the needs of a single welder, who needs to change their work-place. Examples for such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 45kg – let the welder move the unit with ease to the next working location.

ClearO2 Two-welder mobile filtration unit

Designed for the 8XE and 7XE MIG Extractors.

Exceptional filter efficiency IFA >99.8%

Specifications

The ClearO2 W200 is designed to accompany the 8XE and 7XE MIG Extractors from Translas. With the combination of the 8XE and 7XE Extractors range of welding fume torches and ClearO2 W200 units we capture between 90% and 98% of welding fume at the source and filter these with efficiency > IFA 99.8%. The compact unit is perfect for changing location on the job due to its lightweight – only 58 kg – and its four wheels with two lockable.

Automatic Unit

The ClearO2 W200 unit has an automatic cleaning function by reverse compressed air pulse. The moment the pressure in the filter is too high, the unit starts to clean the filter automatically. A manual cleaning function can be done by pressing a single button. Automatic start/stop function to preserve energy and to synchronize the unit with the 8XE and 7XE Extractors is a standard on the ClearO2 units. The moment the torch is out of the specially designed torch holder, the machine automatically starts working. The torch holder is designed to work only with the 8XE and 7XE MIG Extractor.

Continuous Rated Motor

The electric motor of the unit is designed to work continuously without losing power. Maintenance on the unit is minimal due to the automatic cleaning function and the simplified motor system, making it long-lasting and time-saving. With a filter area of 5m², this is one of the most efficient units of its size with the largest filter. The filter is disposable and has an active surface with an efficiency: IFA >99,8%.

Light And Mobile

The ClearO2 W200 unit is designed to serve the needs of a welder, who needs to move around their workplace. Examples for such applications are in shipbuilding, wind tower building, tank construction and other similar fabrication industries. The four wheels with two locks and the lightweight – only 58kg – allow the welder to move the unit with ease to the next working location.

Multi-player Solution

The ClearO2 units are a practical solution for every welding fabrication environment. The W200 units start with a 2-welder solution! Easily switch between single and multiplayer mode by connecting only the amount of extraction torches you need.

Ball valve to reduce the suction flow

Coupler for suction hose black tbv Ø51mm unit side

Coupler to extend the suction hose Ø51mm

Extension cable auto start/stop 5-p plug W-serie

Specifications

Filter W-serie ClearO2

Specifications

Filtermat W-serie ClearO2

Specifications

Pressure reducing valve 5-15bar 1/4-NP7.2

Sensing cable auto start/stop 4mtr W-serie

Specifications

Suction hose for the ClearO2

Specifications

Torch holder for automatic start/stop

Specifications