Locations

Partner Login

Translas Academy

Catalogue

Digital Media

Events

News

Careers

Locations

Partner Login

Translas Academy

Catalogue

Digital Media

Events

News

Careers

Locations

Partner Login

Translas Academy

Catalogue

Digital Media

Events

News

Careers

Locations

Partner Login

Translas Academy

Catalogue

Digital Media

Events

News

Careers

Translas BV

Fahrenheitbaan 2

3439 MD Nieuwegein

The Netherlands

June 14-16, 2022, Toronto – Canada

November 08 -10, 2022, Atlanta – USA

September 11 – 15, 2023, Messe Essen GmbH – Germany

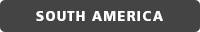

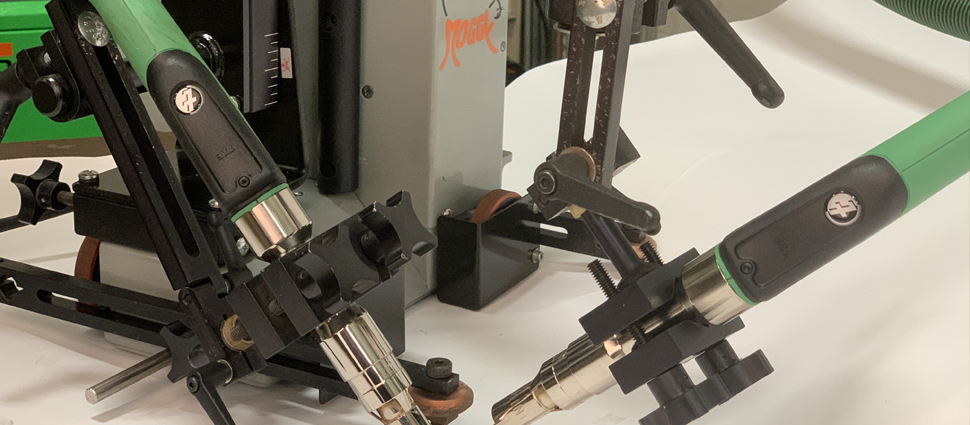

THE NEW MIG AND TIG EXTRACTORS

October 28/2020 – Nieuwegein The Netherlands – Translas, is a Dutch manufacturer of welding torches since 1960. A company founded by welders, for welders with a passion for innovation and new technologies, continually striving to engineer innovat

Read More

October 28/2020 – Nieuwegein The Netherlands – Translas, is a Dutch manufacturer of welding torches since 1960. A company founded by welders, for welders with a passion for innovation and new technologies, continually striving to engineer innovative products that boast a distinctive design and quality and functionality. The company’s goal is to reduce welders’ exposure to hazardous fumes globally and provide a healthier and safer work environment.

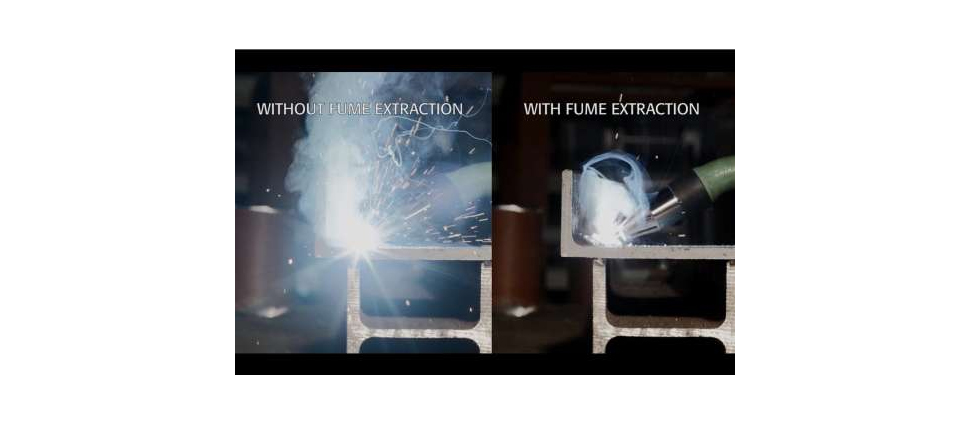

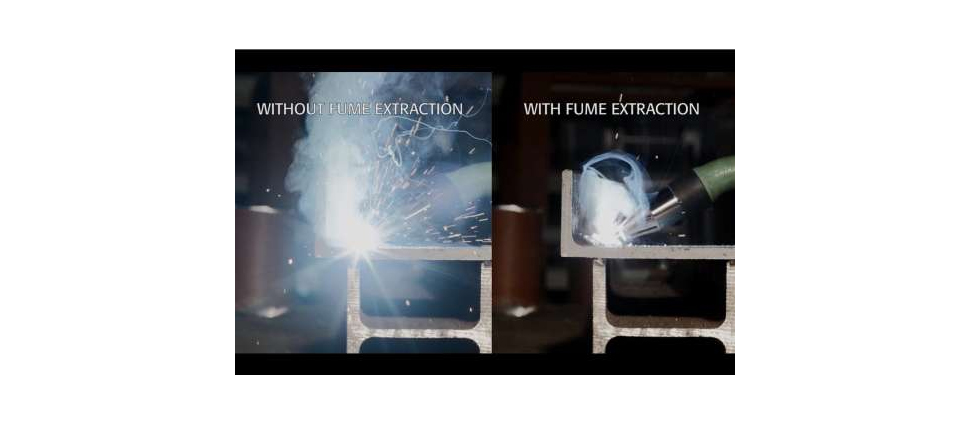

About Welding Fumes: Prolonged exposure is like inhaling ultrafine metal dust which can lead to cancer of the lung, damage to the brain and kidney damage. Certain gases, such as helium, carbon dioxide and argon, displace oxygen and argon can pose suffocation risks, particularly in enclosed work areas. For this reason, Translas, a Dutch welding torch manufacturer, developed fume welding torches – 7XE, 8XE MIG and 8TE TIG Extractors – that extracts the welding fumes directly at the source up to 98%.

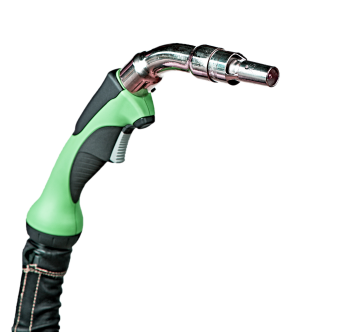

The 8XE MIG Extractor integrates the most efficient fume extraction structure in the welding industry. The torch comes with three different angles, 30° – 45° and straight.

The 8XE MIG Extractor, combined with the ClearO2 W-series 100 and 200, captures up to 98% of welding fumes directly at the source. The 8XE MIG Extractor provides the safest and most effective solution for welders and workers to breathe CLEAN AIR and better work environments. The 8XE Extractor balljoint has a 30° vertical angular movement combined with 360° swivelling. Both with a full stop. Providing excellent maneuverability and leaving cables and hoses untwisted and thereby leakage and breakage free. This combination is new to the market.

The New 8TE-17 Air Cooled and 8TE-30 Water cooled TIG Extractor protect the welders and other workers in the factory from harmful fumes and metals like Aluminium, Chromium, Iron, Manganese and Nickel which are possibly released during the welding process. The 8TE TIG Extractor has a unique ergonomic shape designed to suit the shape of the welder’s hand, fitting perfectly between the thumb and index fingers. The 8TE TIG Extractor engineered to work with the clearO2 T100 and T200 portable units to deliver the best results – up to 95% extraction of welding fumes directly at the source.

Translas Expands With Canadian Division

As of this year, Translas opens its third division. The new entity, officially called Translas Canada Industries Ltd., is located in Woodstock, Canada and aims to serve the whole Canadian market. Manufacturing environments will become cleaner and

Read More

As of this year, Translas opens its third division. The new entity, officially called Translas Canada Industries Ltd., is located in Woodstock, Canada and aims to serve the whole Canadian market.

Manufacturing environments will become cleaner and safer throughout Canada with Translas’ new Woodstock division. Serving the single welder to hundreds of welders, Translas Canada Industries has a comprehensive line of products and services to improve air quality and plant productivity. These include compact mobile units and welding torches with integrated fume extraction to complete fixed solutions for your plant, creating a safer environment for any workforce.

Speaking about Translas’ growth, Jelmer Wolleswinkel, Commercial Director: “Businesses that bring new ideas and innovative solutions to the market are growing. We identified a few markets where we know Translas can make an important contribution to the success of key manufacturing segments. Canada fits our growth and strategic plans perfectly so we’re happy to be a part of the manufacturing community here”.

Duncan Beaumont is the new Executive Director for Translas Canada Industries, serving the whole of Canada. He brings more than 15 years of project management, sales and leadership experience in the Canadian industrial sector and over eight years in the welding, fabrication and fume extraction industry. In his current role at TCI, he helps the welding & fabrication sector select and implement air quality solutions to mitigate health and safety risks and ensure regulatory compliance. With a deep understanding of evolving regulations and Hi-Vac collection technologies, he works with companies to balance regulatory, economic and health and safety needs and design the best overall system for their goals.

Translas Canada Industries is a solution provider for the welding & fabrication industry. They supply welding torches and fume extraction torches with highly efficient, reliable and cost-effective systems. Applications include mild steel, stainless steel, aluminum, MIG & TIG manual and robotic welding. Their expertise and resources can be applied to almost any welding process in the manufacturing environment.

For more information about Translas Canada Industries, visit www.translas.ca .

Very Happy Christmas And A Healthy 2019!

Dear [VOORNAAM], We would like to thank you for working with Translas in 2018. We have had a great year and thanks to our customers, suppliers, and partners, we were able to grow successfully and extend our philosophy in designing and creating bet

Read More

Dear [VOORNAAM],

We would like to thank you for working with Translas in 2018. We have had a great year and thanks to our customers, suppliers, and partners, we were able to grow successfully and extend our philosophy in designing and creating better products which help the safety and comfort of the welder. Our slogan by welders, for welders is not created for marketing purposes only. We really do listen to the welders and create our products based on their needs.

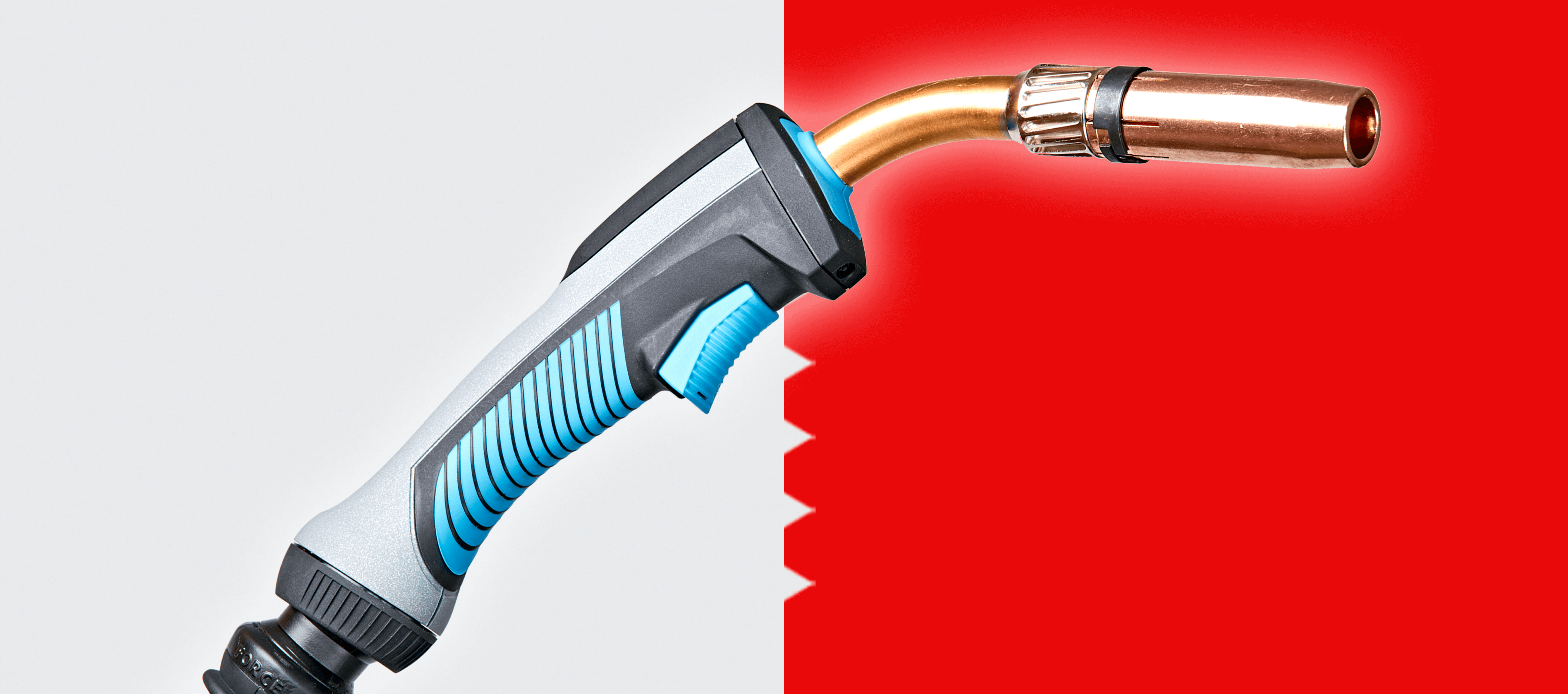

Translas has worked hard in 2018 to update our fume extraction program. The brand ”ClearO2” has been born and we now have a complete fume extraction units program existing, from one-welder up to four-welder units. Furthermore, our latest 8XT TIG line has become state-of-the-art with more module options and availability in several colours.

Another happening of big importance this year was the opening of Translas UK Ltd. in Preston, United Kingdom, in March.

“Having started the business March 2018, we have made great progress through hard work , determination and support from our Dutch colleagues. “ – Gary Keene, Executive Director, Translas UK Ltd.

In 2019, Translas is preparing for another year of steady grow. The focus on the fume extraction range will be increased and new products will be launched to extend the range to be covering more welding process so that all welders can work safely.

Herewith, we would like to wish you a very happy Christmas time with your family and loved ones and a happy and, even more, a healthy 2019! Our team is looking forward to working with you again.

Kindest regards,

Team Translas

Translas To Demonstrate Complete Fume Extraction Solutions At Euroblech

23-26 October 2018 Hall 13, Stand G57 Translas has extended its product range and now offers a whole line of mobile filtration units

Read More

23-26 October 2018

Hall 13, Stand G57

Translas has extended its product range and now offers a whole line of mobile filtration units under the name ClearO2. All ClearO2 units are designed to work with the 7XE Extractor fume torch from Translas. The complete line of high-vacuum units ClearO2 as well as the newest extraction torches will be presented for the first time at EuroBLECH 2018. You will be able to see them with a live demo in Hall 13, booth G57.

Read more about the solution

About EuroBLECH: From 23 – 26 October 2018, the 25th International Sheet Metal Working Technology Exhibition will open its doors again in Hanover, Germany. Amongst sheet metal working specialists, the show is renowned as the key marketplace to find the latest equipment and services in all areas of sheet metal working.

The exhibition presents the entire sheet metal working technology chain: sheet metal, semi-finished and finished products, handling, separation, forming, flexible sheet metal working, joining, additive manufacturing, welding and surface treatment, processing of hybrid structures, tools, quality control, CAD/CAM/CIM systems and R&D. At EuroBLECH, some 1,550 exhibitors from 40 countries present their cutting-edge technology live to a worldwide audience of some 60,000 trade visitors.

Airforce Papr V3 With Flip-up Design NOW IN STOCK

The AirForce V3 is a novelty in the personal protection equipment. It provides air 50x cleaner than the air in the immediate area The biggest benefit of the system is its multi-use: because of the easy flip-up helmet, it is conven

Read More

The AirForce V3 is a novelty in the personal protection equipment. It provides air 50x cleaner than the air in the immediate area

The biggest benefit of the system is its multi-use: because of the easy flip-up helmet, it is convenient for various applications, namely for welding, grinding and cutting. The welder can now have one universal piece of personal protection for all applications.

For the welders who insist on a high-level of protection, the optional new gas filter and improved HD battery offer secure protection from harmful fumes and gases for increased amount of time (from 5 to up to 15 hours and 550 charges battery life).

Download product brochure here.

Now available for order.

New Mobile Fume Extraction Unit - W100

The new fume extraction unit Clear02 W100 is developed to make the job of the welder safer and easier. The machine has been made to work with the 7XE Extractor welding torches from Translas. It is light and mobile, which makes it the perfect companio

Read More

The new fume extraction unit Clear02 W100 is developed to make the job of the welder safer and easier. The machine has been made to work with the 7XE Extractor welding torches from Translas. It is light and mobile, which makes it the perfect companion for the welder who needs to move and change work locations.

With an active filter surface of 5m² and a self-cleaning function, the W100 unit requires minimum effort to maintain. It is available with power supply for 220V-240V and 400V-480V, which makes it suitable to use at any geographic location worldwide.

The Clear02 will be available in stock in the second half of June 2018. For direct pre-orders, contact our team:

Our decision to work towards ISO 9001:2015 accreditation every year demonstrates our commitment to providing a high-quality consistent service to our client and our ongoing investment in technology, development and processes and procedures.

According to the new European privacy Law, GDPR, we are obliged to show you we protect your data and use it wisely. We work mainly with company data and we collect limited personal data, only to make sure we are in touch with the correct person. Read our privacy statement to know what we use your data for:

If you ever wish to adjust your data which you have provided us with, you can always do that via the following link: Change your profile. The link you will always be able to find at the bottom of each newsletter you receive from us.

We’d be happy to answer any of your questions regarding how we use your data. Just shoot us an email. ?

Translas Uk Ltd Opens From 1St March

We are proud to announce that from 1st March 2018, Translas is expanding to the United Kingdom, where we have established Translas UK Limited. About Translas UK Limited Translas UK Limited is based in Preston, North-Western Eng

Read More

We are proud to announce that from 1st March 2018, Translas is expanding to the United Kingdom, where we have established Translas UK Limited.

About Translas UK Limited

Translas UK Limited is based in Preston, North-Western England. It is a fully independent entity with own stock position. The company has to offer all Translas products as well as a complete range of fume extraction equipment for different production environments. Next to the Translas torches, you will be able to see mobile extraction units, purification systems and quality extraction arms – everything you need for your welding workshop.

Exclusive Dealer

Translas UK Ltd. and Translas B.V. in the Netherlands are now exclusive European resellers of the products from RoboVent Solution Group, which specializes in clean air solutions.

“The full-line of dust collection equipment by RoboVent fits nicely with our existing product line and we’re excited to begin offering more integrated solutions to our respective customers. This new direction aligns well with our existing growth plans, especially in the UK.” – Jeroen Boer, Managing Director Translas.

The UK Team

The team in Preston can give you complete customer support, from advice for your workshop to turnkey installations. The team consists of:

Gary Keene ![]()

Executive Director

32 years of technical and sales experience in the fume extraction and welding industry.

Kevin Tatton ![]()

Sales Manager

18 years of experience in the fume extraction and welding industry

Claire Chadwick ![]()

Office Manager

28 years of project management experience in the fume extraction and welding industry

Neil Wadhams ![]()

Business Development Manager

12 years of experience in sales and business development

Our highly-skilled UK team is happy to serve you with their proficiency and expertise. Feel free to contact them with all of your questions via the local office line (+44) 1772 626323 or with an email to info-UK@translas.com.

Kindest regards,

Team Translas UK

Translas Is Awarded With Iso 9001:2015

We are proud to have been again awarded ISO 9001:2015 certification – an internationally recognized standard that ensures our services meet the needs of clients and suppliers through an effective quality management system. Our decision to work t

Read More

We are proud to have been again awarded ISO 9001:2015 certification – an internationally recognized standard that ensures our services meet the needs of clients and suppliers through an effective quality management system.

Our decision to work towards ISO 9001:2015 accreditation every year demonstrates our commitment to providing a high-quality consistent service to our client and our ongoing investment in technology, development and processes and procedures.

Request ISO-certificate

The new ergonomic and durable 8XM MIG are now on stock. The new 8XM MIG torches, with 2K rubber grip and durable structure, can be seen on our website and online catalogue. For quotes, orders and for more information , please, contact us via sales@translas.com or +31(0) 30 604 – 73 73.

See the 8XM line

Meet our products at exhibitions around the world. At some we will be participating personally with a selected team, such as at EuroBLECH in Hanover and at MachTech in Bulgaria. At other exhibitions, you will be able to see our products exhibited by one of our exclusive dealers. Check the schedule on our website and see if we are coming to your country:

Welding Exhibitions 2018

Goodbye, 2017! Hello, 2018!

Time has gone fast. Christmas is approaching and 2017 is almost behind us. It is time to make the balance and to look back at everything that happened during this exciting year. Unfortunately, life brings not only good but also sad moments. Transl

Read More

Time has gone fast. Christmas is approaching and 2017 is almost behind us. It is time to make the balance and to look back at everything that happened during this exciting year.

Unfortunately, life brings not only good but also sad moments. Translas, and in particular the Boer family, had to deal with the loss of, the company founder and father, Mr John Boer. Mr. Boer passed away in May this year at the age of 82. John has given his whole life for the company. Luckily, he could also enjoy travelling with his wife Loes. From 1995 till 2008, they travelled the United States of America and Canada on their motorhome. This was their passion and we are happy they could enjoy it for so many years. We will always remember John & Loes for what they did for us as as company, but mainly, as loving father and mother.

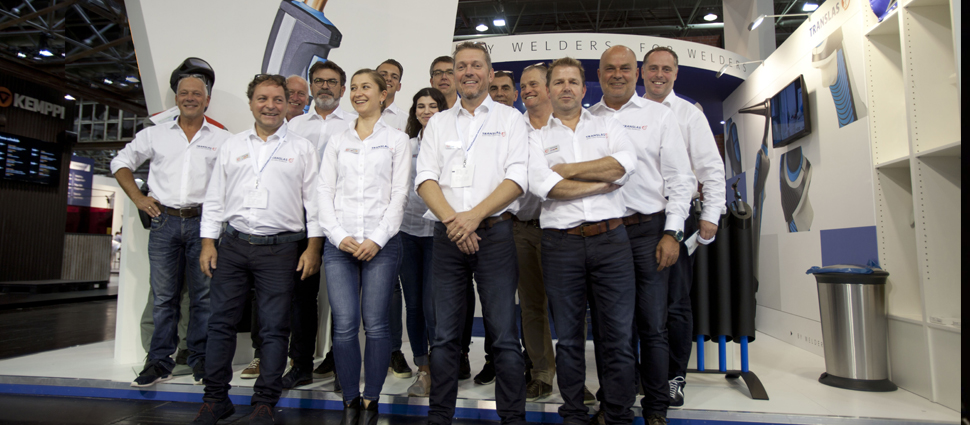

For Translas, 2017 was a fantastic year. The company presentation at the exhibition Schweiβen & Schneiden in Düsseldorf was a major goal. We believe we presented ourselves in a way we never did before. Being located amongst the biggest companies in the industry and the high traffic of people on our booth, made it an incredible experience. In Düsseldorf, we presented our brand new MIG and TIG torch lines – 8XM and 8XT. The reactions of the visitors to the torches as well as to our overall presentation, were more than positive. We are convinced that in 2018 many of you will meet and see this new line of torches and you can judge yourself.

Do you want to take a look at the new torches already? Our new catalogue for 2018 is available online at www.translas.com and as a hardcopy by your request.

2018 has to start yet but we are already excited to make it even better than what 2017 was already. We are ready to serve you at any time and let’s make all a great year out of 2018.

Edwin, Jelmer and Jeroen & the whole Translas team wish you very Happy Christmas holidays with your loved ones and all the best wishes for 2018!

Kindest regards,

Jeroen Boer

Managing Director

Translas BV

Translas With Successful Presentation At Schweissen & Schneiden 2017

Schweissen & Schneiden 2017 was a great success for Translas! During the show we pre-launched the two new torch lines – 8XM MIG & 8XT TIG. The 8th generation of welding torches, with its ergonomics and durability, makes the everyday work

Read More

Schweissen & Schneiden 2017 was a great success for Translas! During the show we pre-launched the two new torch lines – 8XM MIG & 8XT TIG.

The 8th generation of welding torches, with its ergonomics and durability, makes the everyday work of the welder even easier and more comfortable. The new MIG & TIG lines were met with enthusiasm from the visitors on the stand.

There was also a very high interest in the new AirForce PAPR V3 with a flip-up helmet, suitable for various kinds of work, while keeping the air of the welder 50x cleaner than the air in the environment.

To get some impression of our stand and presentation, see the photos below:

If you have any questions and want more information about the 8XM, 8XT or other new products, feel free to contact our team:

If you have any questions and want more information about the 8XM, 8XT or other new products, feel free to contact our team:

Best regards,

Translas Team

New Generation Welding Torches At Schweissen&Schneiden 2017

Tijdens de grootste Europese vakbeurs op lasgebied, ‘Schweissen & Schneiden 2017’, zal Translas een nieuwe generatie MIG & TIG lastoortsen introduceren. De nieuwe

Read More

Tijdens de grootste Europese vakbeurs op lasgebied, ‘Schweissen & Schneiden 2017’, zal Translas een nieuwe generatie MIG & TIG lastoortsen introduceren.

De nieuwe 8XM MIG-toortslijn heeft een onderscheidend ontwerp en tal van verbeteringen, zoals een stabiele grip en een bredere schakelaar. Deze nieuwe duurzame lastoorts onderscheidt zich met een hoog comfort.

Translas zal daarnaast ook de nieuwe lijn 8XT TIG-lastoortsen met een ultra-ergonomisch design introduceren. De handgreep van de 8XT elimineert spanning op de pols. De vergulde veerpencontacten zorgen voor een optimaal contact met de machine zonder het risico op onderbrekingen.

Bezoek ons tijdens ‘Schweissen & Schneiden’ op stand 9B20 in hal 9 en ervaar het comfort van deze nieuwe ultra-ergonomisch ontworpen lastoortsen!

Binnenkort beschikbaar

25/09/2017

Tijdens de beurs in Düsseldorf zijn beide nieuwe toortslijnen in onze catalogus beschikbaar voor pre-order. Binnen enkele weken kunt u de bijgewerkte prijslijst ontvangen, waarin alle nieuwe productintroducties zijn opgenomen. De prijslijst is geldig vanaf 1 oktober 2017.

Met vriendelijke groet,

Team Translas BV

Fume Extraction Solutions

Translas now offers a whole range of fume extraction torches as well as a complete fume extraction solution. The hi-vac extraction solution consists of a 7XE Extractor fume torch & ProCube™– a high-vac filtering unit. MIG fume extraction t

Read More

Translas now offers a whole range of fume extraction torches as well as a complete fume extraction solution. The hi-vac extraction solution consists of a 7XE Extractor fume torch & ProCube™– a high-vac filtering unit.

MIG fume extraction torches are now available in air- and water-cooled versions, as well as with a highly flexible hose which makes them even more manoeuvrable than a regular MIG torch. More options include small XS size torch with a metal swan neck.

Extraction at the source needs high-speed extraction and low air volumes to efficiently remove the fumes. The high-end solution – 7XE Extractor & ProCube™ – includes advanced design features that enable maximum fume suction, while easing the work of the operator who does not need to adjust the flow rate of the shielding gas and can effortlessly transport the system to the location needed.

Click on the button below to see the most popular fume extraction products:

The on-torch fume extraction is suitable for various applications. A fume extraction torch can be used on its own at any location. For larger welding areas, such as workshops, it can be connected to a ducted extraction system or combined with ProCube™. The advantage of the on-torch fume extraction, when compared to traditional systems is that the operator is easily mobile, not needing to consider the extraction hood.

Do you need a special extraction solution? Contact us for an advice: info@translas.com / +31(0)30 – 604 73 73.

Most Effective Fume Extraction

Welders are exposed to welding fumes for extended periods of time. This strongly increases the chance of respiratory problems and leads to decreased productivity. In this video, RTLZ, the Dutch TV business news program, reports on the experience o

Read More

Welders are exposed to welding fumes for extended periods of time. This strongly increases the chance of respiratory problems and leads to decreased productivity.

In this video, RTLZ, the Dutch TV business news program, reports on the experience of working with the 7XE Extractor fume extraction torch, by Translas:

“People are happy to work now” – Hans van Rangelrooij, Stainless Solutions Group

Source: RTLZ – Dutch TV Program

Thanks to the recent developments in the welding torch technology, welding fumes can now be eliminated to almost 100%. See how…

Read article

Translas Wishes You An Inspiring, Healthy And Happy 2017!

2017 has almost arrived and it promises to be a year full of new challenges and positive developments. But first, Translas wants to look back at a successful 2016. A year in which we have worked hard on the continued development of our welding tor

Read More

2017 has almost arrived and it promises to be a year full of new challenges and positive developments. But first, Translas wants to look back at a successful 2016.

A year in which we have worked hard on the continued development of our welding torches. Our torches have made welding healthier for the welder and they have also made it possible to weld difficult-to-reach locations and under hard conditions with a high amperage. To achieve this, Translas has invested heavily in its machinery and 3D printing technology.

For the coming year, we can look ahead to the presentation of the next generation of MIG and TIG welding torches, which we will be introducing during the Schweiβen und Schneiden trade fair in September. We are currently working very hard on the development of this new 8XM and 8XT series. Translas will also present a new flip-up welding helmet and many other innovations and upgrades at this trade fair.

There is more than enough to look forward to. These are all very positive developments, which makes us look forward to 2017 with great confidence.

The Translas team wishes you a Merry Christmas and a Happy New Year!

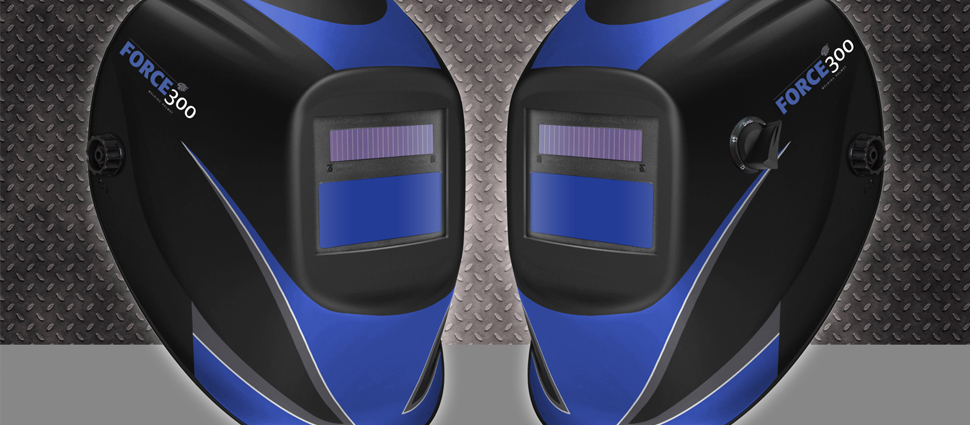

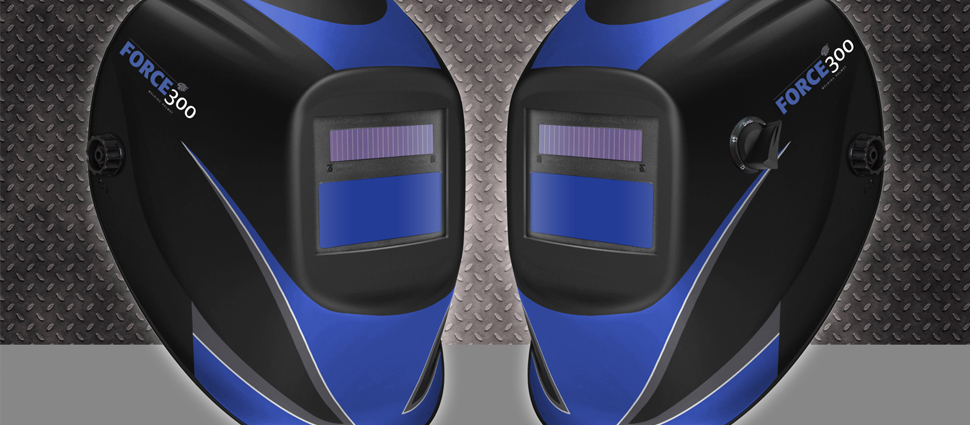

Welcome The New Helmet In The Force Family, Force 300

The new member in the Force family has arrived – the Force 300 welding helmet! The new Force 300 welding helmet is a helmet for universal use and at a great price. The helmet is fully automatic and it covers a range of applications – from Stic

Read More

The new member in the Force family has arrived – the Force 300 welding helmet! The new Force 300 welding helmet is a helmet for universal use and at a great price.

The helmet is fully automatic and it covers a range of applications – from Stick welding and MIG/MIG to low amperage TIG welding and grinding. Its unique modern design and light weight – only 440 g – make it a pleasure to wear during your welding work. The helmet is available also for private labelling.

Due to the Christmas holidays, the Force 300 will be offered at a special price for all orders placed till 31st December 2016! Are you interested in pricing and conditions? Ask our team:

Hans Baas will be leaving Translas after a period of 12 years. Hans is

ready to rise to a new challenge in his career and will be continuing his employment at Kemetyl in Soest, a manufacturer and distributor of professional cleaning and maintenance products for the (automotive) industry. Hans has been of tremendous value to Translas over the past

12 years and has always been fully committed to the company.

We would therefore like to extend our heartfelt thanks to Hans for the

past 12 years and would like to take this opportunity to wish him all the very best at his new employer!

When we asked Hans whether he would like to add a personal note, his answer was as follows:

“I have greatly enjoyed working at Translas over the past 12 years and I would like to start off by wishing all of my colleagues all the very best for the future. I would also like to thank Translas’ customers for the very enjoyable working relationship and pleasant contact”.

Highlights From Euroblech 2016

Translas starts a strategic partnership with RoboVent During EuroBLECH in Hanover last week, Translas officially announced the start of a partnership with the North American leader in clean air – RoboVent. The plan of the two companies is

Read More

During EuroBLECH in Hanover last week, Translas officially announced the start of a partnership with the North American leader in clean air – RoboVent. The plan of the two companies is to help each other expand on both continents and includes various projects. We will be integrating our product lines to deliver exceptional fume extraction solutions.

“We have been looking for a suitable partner for our products for long time. Our mission and vision about minimizing health risks for welders match with the ones of RoboVent. We believe this is the reason why the fume extraction machines of RoboVent work perfectly with the 7XE Extractor welding torch of Translas.”, says Jelmer Wolleswinkel, Commercial Director at Translas B.V.

After introducing the 7XE Extractor to the North American market, RoboVent is now actively working together with Translas throughout Europe. They have already developed the ProCube, a fume extraction unit designed specifically to pair with the 7XE Extractor.

The next step of the partnership is to develop additional fume extraction machines suitable for the European market. Translas is going to participate by giving its know-how derived from 55 years of experience in the welding market in Europe.

“Our goal is to significantly improve the health of welders around the world by creating innovative and sustainable solutions against welding fumes.”, states Jeroen Boer, Managing Director Translas B.V.

The other novelty Translas presented during EuroBLECH was the second line of fume extraction torches – 7XE ExtractorFlex. The Flex line is characterized by 50% more flexible hose.

The 7XE ExtractorFlex was presented for the very first time to the public last week. It received enormous amount of attention, positive feedback as well as direct first orders. The Flex is mainly appreciated in situations when the welder needs to constantly switch positions and angles. When welding with a torch with regular hose, this results in tension and, possibly, even pain in the wrist. With the Flex the tension in the wrist from the daily work is minimized.

The Flex has an extra layer of leather protection which can be partially or completely covering the hose, according to your needs.

Are you interested in trying out the new 7XE ExtractorFlex?

Click here to request a free demo.

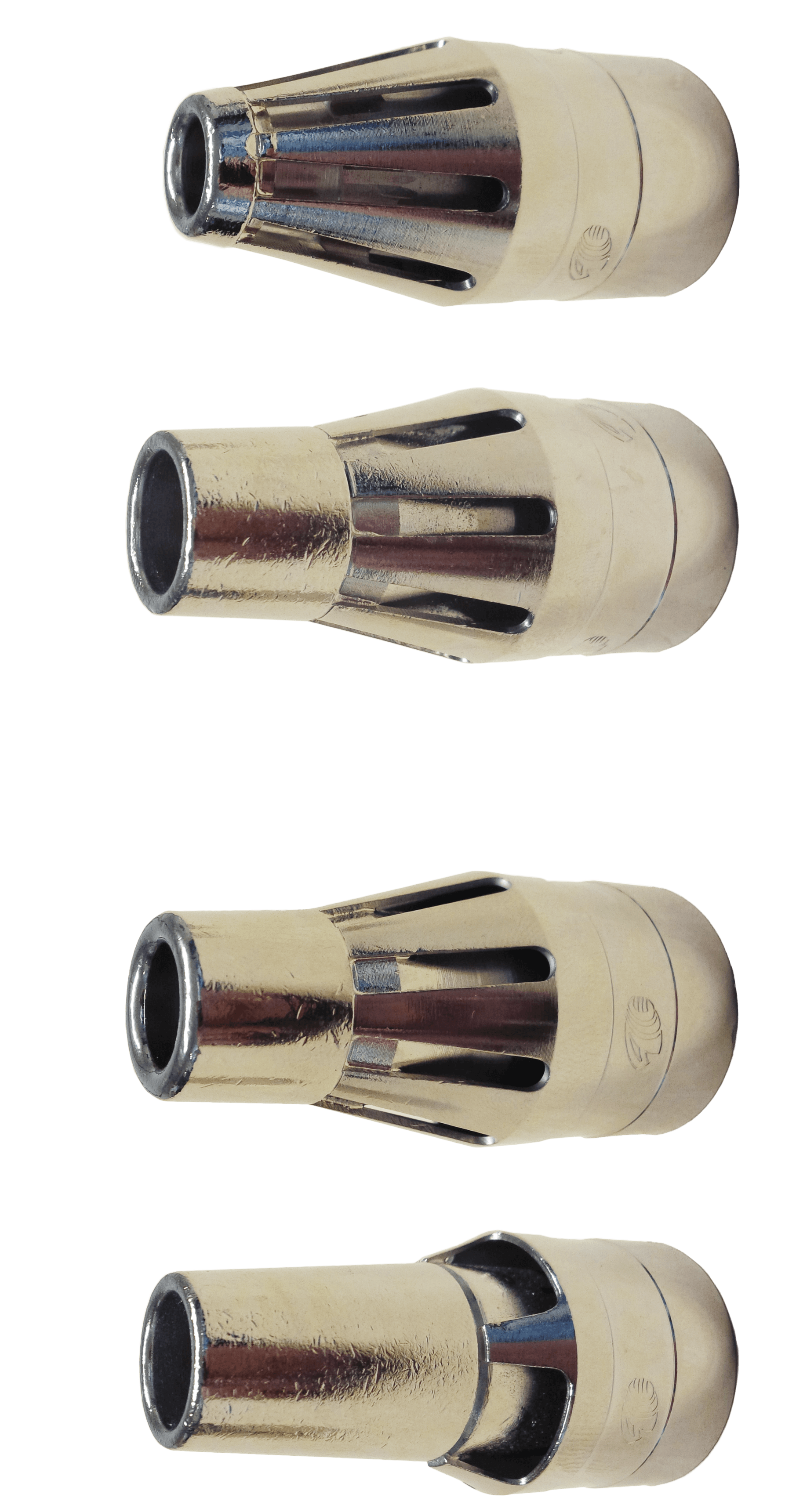

4 nozzles for different applications

Both 7XE Extractor and 7XE ExtractorFlex are available with the four new nozzles – 10mm, 12mm Standard, 14mm and 14mm Special. You can switch the nozzles in seconds. Thus, the range of application is broadened to almost any single need you might have as a welder.

10mm

Suitable for most common applications. Provides focused shielding gas flow and immediate removal of fume on typical butt-,

t-fillet and lap-joints.

12mm Standard

The standard fume nozzle supplied with each 7XE Extractor / 7XE ExtractorFlex. The nozzles offers slightly wider shielding gas coverage on medium-thickness materials in butt and fillet applications, and outside-corner joints.

14mm

For heavier-thickness, high-current and high-deposition butt- and lap-joint applications, this nozzle offers greater shielding gas coverage to help prevent porosity.

14mm Special

Where space is limited and fit is tight on acute-angled fillet joints, or into steep prepped roots on heavy-thickness butt-joints, this nozzle offers better access and greater shielding gas coverage to reduce porosity.

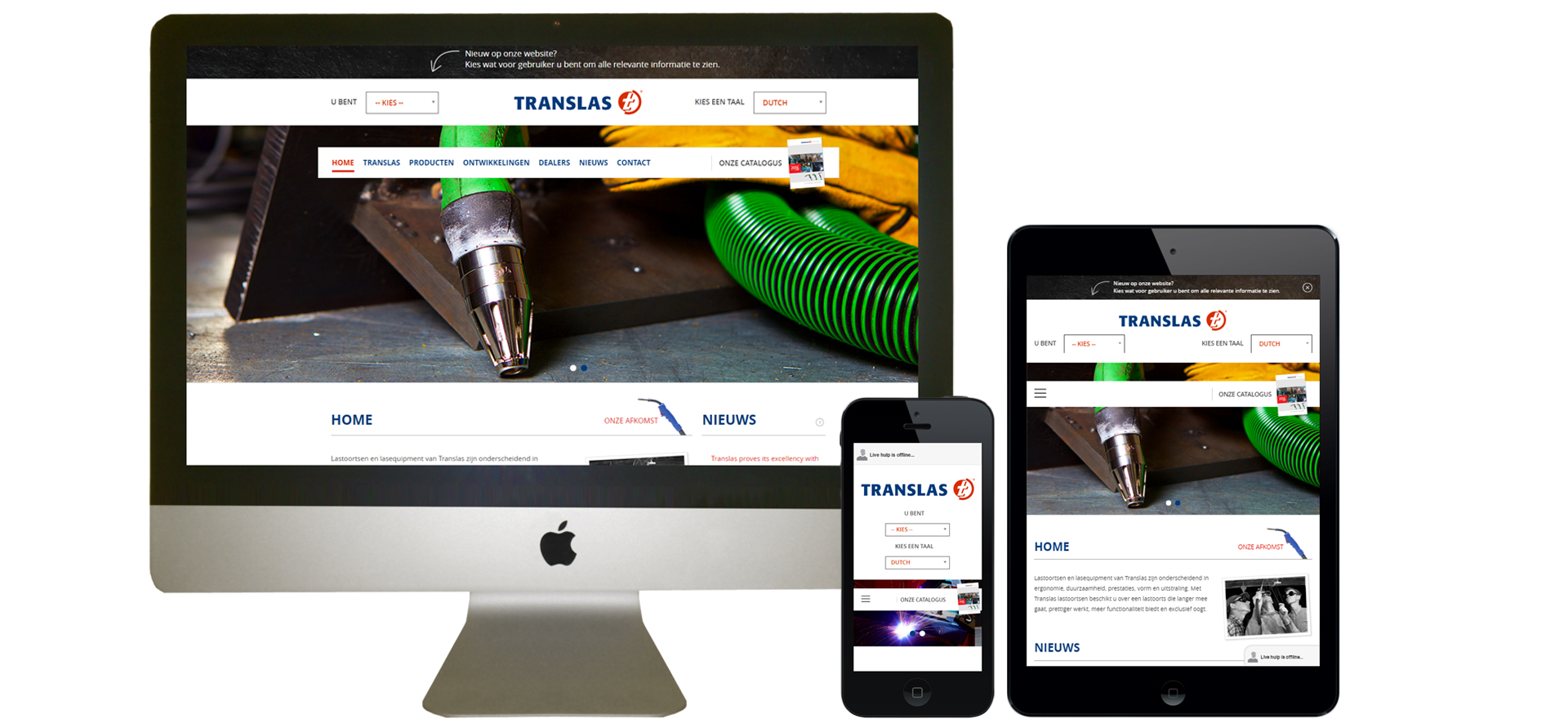

New Website And More

New Website We are happy to present our new website. The website is now with co

Read More

We are happy to present our new website. The website is now with completely new look and feel which we feel more in line with. There you are able to find all our products with detailed product sheets, other useful information and you can get in touch with us via our chat function.

In order to easily find the information most relevant to you and your business, we have added the option user type on the main home page. Are you a dealer of welding products, an OEM or an end user? Choose your user type and get straight to the information you need. Are you simply interested in our company? Then you do not need to make any choice.

Dealer panel: As on the previous website, you can still download useful materials, such as manuals, brochures, catalogues and various photos from the dealer panel. If you are not yet registered, you can do it here (hyperlink).

Feel free to visit the website and look around to get acquainted. We would be happy to receive your feedback and answer your questions: info@translas.com .

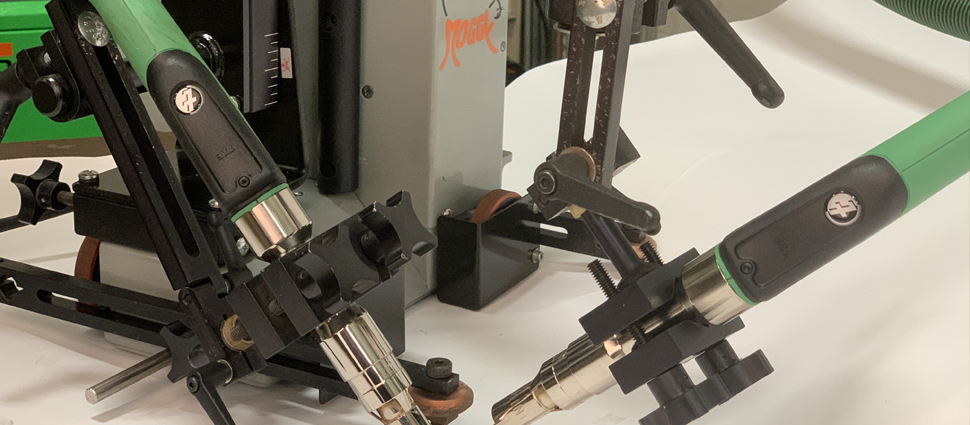

Translas Announces A Future Forward Global Distribution Partnership With Gullco International Limited

“A future forward alliance for a healthier and more efficient welding industry” January 22/2020- Nieuwegein, The Netherlands - Translas, a premier global manufacturer and leader in on- torch fume e

Read More

“A future forward alliance for a healthier and more efficient welding industry”

January 22/2020- Nieuwegein, The Netherlands – Translas, a premier global manufacturer and leader in

on- torch fume extraction, has announced a partnership with GULLCO International Limited. With this partnership, GULLCO will serve as the global distributor of Translas’ newest fume extraction solutions, such as the Translas 7XE Semi-Automatic Fume Extraction welding torch and the ClearO2 W-Series hi-vac units, designed and engineered for welding automation.

on- torch fume extraction, has announced a partnership with GULLCO International Limited. With this partnership, GULLCO will serve as the global distributor of Translas’ newest fume extraction solutions, such as the Translas 7XE Semi-Automatic Fume Extraction welding torch and the ClearO2 W-Series hi-vac units, designed and engineered for welding automation.

As the announcement was made, Translas Canada’s Executive Director Duncan Beaumont commented, “We are very pleased to partner with GULLCO as our global distributor of the Translas fume extraction solutions, the 7XE Semi-Automatic Fume Extractor welding torch in combination with the ClearO2 W-Series hi-ac units. With air quality regulations being a growing concern globally and with automation gaining traction worldwide, we see a strong potential for growth in a wide variety of applications. GULLCO has been a leader for more than 66 years in the automation industry and is a trusted international manufacturer and world supplier of welding automation including welding carriages, cutting carriages and plate beveling machines for automated welding and cutting to global manufacturing brands. GULLCO is an ideal partner for Translas and we look forward to a successful collaborative partnership.”

GULLCO is pleased to work with Translas as a premier partner and to add the 7XE Semi-Automatic Fume Extractor torch and ClearO2 W-Series hi-vac units to their portfolio of products designed with exceptional engineering. According to Nick Drake, GULLCO’s Global Marketing Manager, “GULLCO is enthusiastic to enter into an exclusive distribution agreement with Translas to further influence the welding industry with a future forward alliance.”

Welding fumes contain vapours, a mixture of airborne gas by-products and fine particles. The composition of the mixture depends on the welding method and the products that are welded. The vapours and gases released during welding can lead to serious health problems. Short-term exposure can result in nausea, dizziness, or eye, nose and throat irritation. Prolonged exposure to welding fumes can lead to cancer of the lung, larynx and urinary tract, as well as nervous system and kidney damage. Certain gasses, such as helium, carbon dioxide and argon, displace oxygen and argon can pose suffocation risks, particularly in enclosed work areas.

Extraction at the source proves to be the safest and most effective solution to achieve a healthier work environment. The Translas 7XE Semi-Automatic Fume Extractor is a welding torch engineered to capture hazardous welding fumes directly at the source. The Translas fume extraction solution extracts up to 95% of the welding fumes directly at the source. When using the Translas 7XE in combination with the ClearO2 W-Series hi-vac units, the harmful welding fumes and individual particulates are no longer released directly into the air; they are captured immediately as generated.

Link to videos:

Translas 7XE Fume Extractor welding guns and GULLCO Moggy® Automated Trackless Welding Carriage in action

Translas 7XE Fume Extractor welding gun on source fume extraction nozzle closeup

The ClearO2 mobile filtration units are designed to accompany the 7XE Semi-Automatic Fume Extractor torches and work efficiently in combination with the GULLCO KAT® or Moggy®.

The 7XE Semi-Automatic Fume Extractor and the ClearO2 hi-vac units offer powerful filtration with an efficiency > IFA 99.8%. The units are compact, lightweight and mobile, making it easy to change locations on the job.

About Translas – “Engineering the new standards by welders for welders”

Translas is a Dutch manufacturer of welding guns since 1960, founded “by welders, for welders” with a passion for innovation and new technologies. We engineer innovative products that boast a distinctive design as well as quality and functionality.

Welders’ safety is of paramount importance to Translas. The company’s goal is to globally reduce

workers’ exposure to hazardous fumes and to provide a healthier and safer work environment, therefore establishing higher productivity and profitability. Some of our pioneering products include fume extractor guns with a built-in module to safely extract welding fumes at the source and portable extraction units.

Translas has grown at a fast pace over the last few years. With the recent opening of Canadian distribution channels the company is focusing on key partnerships with companies utilizing smart technologies globally to influence today’s manufacturing industry towards “the future”.

For more information please contact info@translas.com or visit www.translas.com

GULLCO International was formed in 1954 to serve the demands of the emerging welding industry in North America. GULLCO is a family owned company, with its world headquarters located in Newmarket, Ontario, Canada. GULLCO International serves the entire world market through its companies in Canada, United States, United Kingdom, India, Australia, and China as well as its strong worldwide distributor network with high quality automated welding machines for welding and cutting applications. GULLCO International is engaged in a continuous research and development program to provide weld automation equipment and systems geared to the fast-changing needs of the welding industry and equipment that can stand up to the tough environments in the field. GULLCO is dedicated to providing productivity, cost savings, durability and service. KAT®, Moggy®, SAM®, KBM® and KATBAK® are registered trademarks of GULLCO Enterprises Limited.

For more information please visit www.gullco.com

Irina Pljusznyin

Global Marketing Manager

Translas

irina@translas.com

+1 226-298-0732

Translas Demonstrates Most Efficient Fume Extraction Solution At Euroblech 2018

Translas – the Dutch welding torch manufacturer – has extended its product range and now offers a whole line of mobile filtration units under the name ClearO2. All ClearO2 units are designed to work with the 7XE Extractor fume torch from Translas

Read More

Translas – the Dutch welding torch manufacturer – has extended its product range and now offers a whole line of mobile filtration units under the name ClearO2. All ClearO2 units are designed to work with the 7XE Extractor fume torch from Translas. The complete line of high-vacuum units ClearO2 as well as the newest extraction torches will be presented for the first time at EuroBLECH 2018. You will be able to see them with a live demo in Hall 13, booth G57.

The 7XE Extractor with a ClearO2 unit capture between 90% and 95% of welding fumes at the source and filter these with an efficiency > IFA 99.8%.

Welding fumes contain vapours, gases and smoke particles that form a health hazard. People assume that local extraction arms, extraction hoods and mobile filters adequately protect welders against exposure to welding fumes. But in practice these measures tend to be insufficiently effective: not only for the welders themselves, but also for others working in the same area.

Extraction at the source proves to be the safest solution because harmful welding fumes are no longer released directly into the air breathed by personnel, as found by the Dutch research institute TNO.

The 7XE Extractor reduces the amount of welding fumes in the workplace to less than 1 mg/m3 during an 8-hour working day (the statutory standard for welding fumes in Germany is 1,25 mg/m3). The 7XE Extractor can be used for almost any MIG/MAG welding process.

The extraction torches from Translas feature a built-in extraction module at the gas nozzle. The gas nozzle is conical with a gas orifice of 12 mm. This gives an excellent view and accessibility to the weld. The 7XE Extractor is a very light torch – varies from only 1,1 kg to 1,5 kg (lighter than a regular 510 torch). Due to the small size of the handle and its ergonomic form, the welder does not feel any difference between the 7XE Extractor and a standard welding torch.

7XE MINI Extractor weighs only 1.1 kg and has a small in size handle and nozzle as well as small conical hose (from 30 mm to 38 mm). It was developed especially for welding jobs where constant changing in positions is required, such as in manual automotive welding.

The extraction torches from Translas can be ordered with a plastic or with a metal neck. The metal neck is preferred for higher-impact environments (7XE MINI Extractor is available only with metal neck).

All 7XE Extractor torches , both gas and water cooled, are with 100% Duty Cycle.

Extraction at source needs high speed extraction and low air volumes to efficiently remove the fumes. This means that it needs to be connected to a high-vacuum unit, such as one of the ClearO2 units.

Designed especially for the 7XE Extractor fume torch, ClearO2 filtration units are the only portable filtration solution of its size that is rated for high-production welding environments. The 7XE Extractor & ClearO2 filtration solution is a powerful, flexible system that can be used for a variety of welding applications. The size and portability make it excellent choice for high-mobility applications such as shipbuilding or large fabricated components. This high-end solution includes advanced design features that enable maximum fume suction, while easing the work of the operator . The system is effortlessly transported to the location needed.

All EuroBLECH visitors are invited for a demonstration of effective welding fume extraction at Translas’ booth in Hall 13, number G57. Translas brings together almost 60 years of expertise in welding torch manufacturing with know-how in welding fume extraction to offer the most effective welding fume solutions to the market.

ClearO2 W100 unit for one-welder with 7XE Extractor

ClearO2 W200 – 2-welder unit

ClearO2 W400 – 4-welder

Translas Expands With A New Limited Entity In England

Nieuwegein, NL, march 2018 – From 1st March 2018, Translas is expanding to the United Kingdom, where we have established Translas UK Limited. Translas UK Limited is based in Preston, North-Western England. It is a fully independent entity with o

Read More

Nieuwegein, NL, march 2018 – From 1st March 2018, Translas is expanding to the United Kingdom, where we have established Translas UK Limited.

Translas UK Limited is based in Preston, North-Western England. It is a fully independent entity with own stock position. The company has to offer all Translas products as well as a complete range of fume extraction equipment for different production environments. Next to the Translas torches, you will be able to see mobile extraction units, purification systems and quality extraction arms – everything you need for your welding workshop.

Exclusive Dealer

Translas UK and Translas B.V. are now also exclusive European resellers of the products from RoboVent Solution Group, which specializes in clean air solutions.

“The full-line of dust collection equipment by RoboVent fits nicely with our existing product line and we’re excited to begin offering more integrated solutions to our respective customers. This new direction aligns well with our existing growth plans, especially in the UK.” – Jeroen Boer, Managing Director Translas.

The UK Team

The team in Preston can give you complete customer support, from advice for your workshop to turnkey installations. The team consists of:

Gary Keene, Executive Director with 32 years of technical and sales experience in the fume extraction and welding industry.

Kevin Tatton, Sales Manager with 18 years of experience in the fume extraction and welding industry.

Claire Chadwick, Office Manager with 28 years of project management experience in the fume extraction and welding industry.

Neil Wadhams , Business Development Manager with 12 years of experience in sales and business development.

Feel free to contact our highly-skilled UK team with all of your questions via the local office line (+44) 1772 626323 or with an email to info-UK@translas.com.

Translas Is Nominated For The Welding World Awards 2018

10 november 2017, Nieuwegein - For the first time, Translas, the Dutch welding torch manufacturer, is nominated for The Welding World Awards in the category Best New Welding Product Supplier. We are proud to be nominated among the best in the welding

Read More

10 november 2017, Nieuwegein – For the first time, Translas, the Dutch welding torch manufacturer, is nominated for The Welding World Awards in the category Best New Welding Product Supplier. We are proud to be nominated among the best in the welding industry.

More about The Welding World Awards: The awards are organized by the Welding World Association for second year in a row. The aim of The Welding World Awards is to seek out examples of being the best at what we do, acknowledging and rewarding those people and companies that provide a good service to their customers and deserve the recognition for it.

If you believe in Translas, give your vote here:

You have time till 30th November 2017. Every vote counts!

We appreciate your support and we continue working to bring the most sustainable solutions for the welding industry out.

New Welding Torches From Translas Shine In Regard To Ergonomics And Durability

Nieuwegein, Netherlands, October 2017 – During the German welding and cutting trade show ‘Schweißen & Schneiden 2017’, Translas, a manufacturer of welding torches, introduced a new generation of MIG & TIG welding torches. The new line

Read More

Nieuwegein, Netherlands, October 2017 – During the German welding and cutting trade show ‘Schweißen & Schneiden 2017’, Translas, a manufacturer of welding torches, introduced a new generation of MIG & TIG welding torches. The new line of torches 8XM and 8XT, which by now represent the 8th generation, shine in regard to ergonomics and durability. With this, Translas offers torch lines that make the daily welding work even easier and more comfortable.

An excellent grip, solid construction, low weight, high operational reliability and the pleasant manner in which the torches lie in your hand all form the unique characteristics of both lines of torches.

For example, the handles of both welding torches have been fitted with a new ribbed structure with 2K rubber inlays, which provide an optimal grip on the torch and moreover the torch has been given a unique design. As a result, the introduction of the new line of torches immediately received a very positive response.

The new 8XM MIG welding torch line is comprised of 15 different types, up to a 380 ampere gas-cooled torch and a 550 ampere water-cooled torch. In addition to the grip, the MIG welding torches of the 8XM line have also been equipped with a switch that is 30% larger, enabling easier switching.

The high cooling capacity of the Translas MIG welding torches due to the unique construction of the swan necks has always been a distinguishing feature. Translas additionally claims to achieve 15% better cooling than with traditional swan necks.

Due to their use for more detailed welding work, the feel with which TIG welding torches lie in the welder’s hand is always a deciding factor. During the design of the new 8XT TIG welding torch line, Translas has fully placed the focus on ergonomics. This has resulted in a handle that has been ergonomically designed down to the smallest detail in order to provide the welder with the greatest possible comfort and to eliminate any tension in the wrist or fingers. For this, among others additional grip lines have been added at both the bottom as well as the top side, a bump at the bottom side lies between the thumb and index finger, as a result of which more stability is provided in each welding position.

An additional striking innovation is the possibility of rotating the torch body to three positions: straight as well as 45 degrees to the left and right. In this manner, it is possible to also reach areas that are difficult to access when welding.

In order to increase durability and operational reliability even further, Translas has also optimally shielded the PCB module in the machine contact, preventing the disruptive influence of high frequencies and contamination.

The new torch lines 8XM and 8XT will be delivered worldwide in more than 50 countries via a select dealer network.

Translas Launches New Generation Welding Torches At Schweissen & Schneiden 2017

4 September 2017, Nieuwegein, NL - During the biggest welding show Schweissen & Schneiden 2017, Translas will exhibit new generation MIG & TIG welding torches. The new 8XM MIG line has a distinctive design and numerous improvements, such a

Read More

4 September 2017, Nieuwegein, NL – During the biggest welding show Schweissen & Schneiden 2017, Translas will exhibit new generation MIG & TIG welding torches.

The new 8XM MIG line has a distinctive design and numerous improvements, such as steady grip and wider switch. The torch offers great comfort and long durability.

Translas will also pre-launch the new 8XT TIG welding torch line with ultra-ergonomic design. With the 8XT any tension on the wrist and fingers is eliminated. The gold-plated spring pin contacts ensure machine contact with no interruptions.

To meet the new torches for the first time, visit Translas at Schweissen & Schneiden:

booth 9B20, Hall 9.

Düsseldorf

25-29.09.2017

Tv Program On The Most Effective Fume Extraction Equipment

Welders are exposed to welding fumes for extended periods of time. This strongly increases the chance of respiratory problems and leads to decreased productivity. In this video, RTLZ, the Dutch TV business news program, reports on the experience

Read More

Welders are exposed to welding fumes for extended periods of time.

This strongly increases the chance of respiratory problems and leads to decreased productivity.

In this video, RTLZ, the Dutch TV business news program, reports on the experience of working with the 7XE Extractor fume extraction torch, by Translas:

“People are happy to work now” – Hans van Rangelrooij, Stainless Solutions Group

The Newcomer In Our Welding Helmets Range – Force 300!

The new member in the Force family has arrived – the Force 300 welding helmet! The new Force 300 welding helmet is a helmet for universal use and at a great price. The helmet is fully automatic and it covers a range of applications – from Stic

Read More

The new member in the Force family has arrived – the Force 300 welding helmet! The new Force 300 welding helmet is a helmet for universal use and at a great price.

The helmet is fully automatic and it covers a range of applications – from Stick welding and MIG/MIG to low amperage TIG welding and grinding. Its unique modern design and light weight – only 440 g – make it a pleasure to wear during your welding work. The helmet is available also for private labelling.

Due to the Christmas holidays, the Force 300 will be offered at a special price for all orders placed till 31st December 2016! Are you interested in pricing and conditions? Ask our team:

Translas Starts A Strategic Partnership With Robovent

During EuroBLECH in Hanover last week, Translas officially announced the start of a partnership with the North American leader in clean air – RoboVent. The plan of the two companies is to help each other expand on both continents and includes vario

Read More

During EuroBLECH in Hanover last week, Translas officially announced the start of a partnership with the North American leader in clean air – RoboVent. The plan of the two companies is to help each other expand on both continents and includes various projects. We will be integrating our product lines to deliver exceptional fume extraction solutions.

“We have been looking for a suitable partner for our products for long time. Our mission and vision about minimizing health risks for welders match with the ones of RoboVent. We believe this is the reason why the fume extraction machines of RoboVent work perfectly with the 7XE Extractor welding torch of Translas.”, says Jelmer Wolleswinkel, Commercial Director at Translas B.V.

After introducing the 7XE Extractor to the North American market, RoboVent is now actively working together with Translas throughout Europe. They have already developed the ProCube, a fume extraction unit designed specifically to pair with the 7XE Extractor.

The next step of the partnership is to develop additional fume extraction machines suitable for the European market. Translas is going to participate by giving its know-how derived from 55 years of experience in the welding market in Europe.

“Our goal is to significantly improve the health of welders around the world by creating innovative and sustainable solutions against welding fumes.”, states Jeroen Boer, Managing Director Translas B.V.

Translas With Live Welding Demo At Euroblech 2016

Translas will present the 7XE Extractor and its new range of applications before a large international audience at EuroBLECH 2016 in Hannover. Visitors will be able to see the 7XE Extractor in action and will be convinced by its ability to reduce wel

Read More

Translas will present the 7XE Extractor and its new range of applications before a large international audience at EuroBLECH 2016 in Hannover. Visitors will be able to see the 7XE Extractor in action and will be convinced by its ability to reduce welding smoke by 90-95%.

Since its launch in January last year, the 7XE Extractor has taken off and this has made us think about all the different situations in which welders could use this torch. Therefore, we developed 4 new nozzles and an additional highly flexible hose. They will be exhibited for the first time in Hannover this month. The new nozzles allow the 7XE Extractor to be used in various situations, such as welding aluminium or welding at difficult angles, without compromising the quality of the weld.

Visit Translas at Stand A03, Hall 12.

Jelmer Wolleswinkel and his team will be there to answer your questions and to demonstrate the incredible results achieved with the 7XE Extractor with a live welding demo.

About EuroBLECH: From 25 – 29 October 2016, the 24th International Sheet Metal Working Technology Exhibition will open its doors again in Hannover, Germany. Amongst sheet metal working specialists, the show is renowned as the key market place to find the latest equipment and services in all areas of sheet metal working.

The exhibition presents the entire sheet metal working technology chain: sheet metal, semi-finished and finished products, handling, separation, forming, flexible sheet metal working, joining, additive manufacturing, welding and surface treatment, processing of hybrid structures, tools, quality control, CAD/CAM/CIM systems and R&D. At EuroBLECH, some 1,600 exhibitors from 40 countries present their cutting-edge technology live to a worldwide audience of some 60,000 trade visitors.

Translas Is At The Finals Of The Accenture Innovation Awards!

On 26th September at 19.10 the time had come. Jeroen Boer had to present in a one-minute pitch the innovation behind the 7XE Extractor. This was followed by a 10-minute barrage of questions from the jury. In front of 20 jury members, the Pitcher f

Read More

On 26th September at 19.10 the time had come. Jeroen Boer had to present in a one-minute pitch the innovation behind the 7XE Extractor. This was followed by a 10-minute barrage of questions from the jury.

In front of 20 jury members, the Pitcher from Translas had to answer various questions regarding the technical feasibility and commercial expectations for the 7XE Extractor. This was a challenging but enjoyable experience.

At 22.30 the same evening, we were happy to hear the good news – that we are chosen for the finals out of 800 innovations in the category ‘Smart Industry’. On 28th October, we will be competing with four other innovations for the wanted trophy!

The finals will take place at a special arena at DeFabrique in Utrecht, the Netherlands, where we will pitch once again the innovation behind the 7XE Extractor in front of a large supporting audience. You are welcome to support us as well during this event:

Accenture Innovation Summit

Address: DeFabrique Westkanaaldijk 7, 3542 DA Utrecht

Date: 28th October 2016

In case you cannot attend, you still have the chance to support us for the Audience Award by giving your vote(s) on the website:

Vote for the 7XE Extractor

Every person is allowed to give a maximum of 3 votes – via Facebook, Twitter and LinkedIn. Please, spread the word by asking your colleagues, family and friends to give their votes as well. Help us win the prize and to create a real impact on society!

With gratitude,

the Translas Team

At the Semi finals of the AIA16

New Double Cooled Torches Available

The popular double cooled torches, 7XM 460DK and 560DK, have a completely new design. This makes them the torches with the best cooling for high amperage welding. The DK series are small torches with a very high cooling capacity. The temperature s

Read More

The popular double cooled torches, 7XM 460DK and 560DK, have a completely new design. This makes them the torches with the best cooling for high amperage welding.

The DK series are small torches with a very high cooling capacity. The temperature stays at all times below 90°C. To make this possible, a careful assembly process is required. The unique about the cooling system of the DK is that the cooling reaches both the swan neck and the contact tip. The gas nozzle in the 560DK model is also cooled. Both models can be used for up to 500 Amp with mixed gases and C02.

Heat tests have shown that the temperature on the M8 contact tip of the new 7XM-560 torches is lower than 90°C. Comparable MIG welding torches have a temperature of at least 250°C or higher.

7Xe Extractor Suitable For All Kinds Of Applications

The popular 7XE Extractor - torch with integrated fume extraction – has expanded its range of application due to the development of 4 new nozzles. 7XE Extractor took off after its launch last year in October and many saw the future of welding in

Read More

The popular 7XE Extractor – torch with integrated fume extraction – has expanded its range of application due to the development of 4 new nozzles.

7XE Extractor took off after its launch last year in October and many saw the future of welding in the on-torch fume extraction. The high interest in the welding torch made us think about all the different situations welders would use this torch in. Therefore, we developed 4 new nozzles.

The 4 new nozzles types include a 10 mm , 12 mm, 14 mm and 14 mm Specials. As a standard, the Extractor is going to be offered with the 12 mm nozzle, which is much less dependent on the gas flow and ensures no porosity when welding in corners. The 14 mm is your best bet when it comes to welding aluminium. And the 14 mm Specials is excellent for welding at extreme angles, for example of 25 – 30 degrees. Such application can be often found in the welding of ships where welders need to be able to weld at all angles and in every position. The quality of welds in ship building is essential and the 14mm Specials nozzle is made exactly for such critical situations.

The 7XE Extractor is going to be soon delivered as a standard with 12 mm nozzle. The rest can be purchased separately to cover most range of welding situations. For more information, please, contact our sales team at info@translas.com or give us a call: +31(0) 30 – 604 73 73.

From Designing To Injection Moulding

Translas is pleased to offer the possibility for manufacturing of custom moulds. We do this via our daughter company, TA Pacific, based in Dongguan , China, in the province of Guangdong. TA Pacific’s strength is in injection moulding tools, from de

Read More

Translas is pleased to offer the possibility for manufacturing of custom moulds. We do this via our daughter company, TA Pacific, based in Dongguan , China, in the province of Guangdong. TA Pacific’s strength is in injection moulding tools, from designing to the injection moulding. Having the 3-D designing in-house, it is easy to design the product, make mould drawings and manage the manufacturing of the moulds. As options, 1K as well as 2K are both possible.

Another advantage of TA Pacific is their work with PCB’s and all kinds of cable assemblies for the electrical side. TA Pacific is your hands in China, with all necessary quality control in place.

Interested in knowing more? Please, do not hesitate to make an appointment with us:

Translas Proves Its Excellency With Iso 9001:2008

After intensive training period of our team, we passed the certification process according to ISO 9001:2008. In the beginning of this month, Translas officially received the belonging certificate which can be downloaded from the Dealer panel on our w

Read More

After intensive training period of our team, we passed the certification process according to ISO 9001:2008. In the beginning of this month, Translas officially received the belonging certificate which can be downloaded from the Dealer panel on our website.

The standard proves that Translas meets the requirements of this excellent quality management system. We strive for continuous improvement for successful relationship with our partners. We do this through development, manufacturing and trade of components and products for the welding industry as well as technical components based on customer specification.

We invite you with your demands and requests, which we will transfer into standard solutions or specialties.

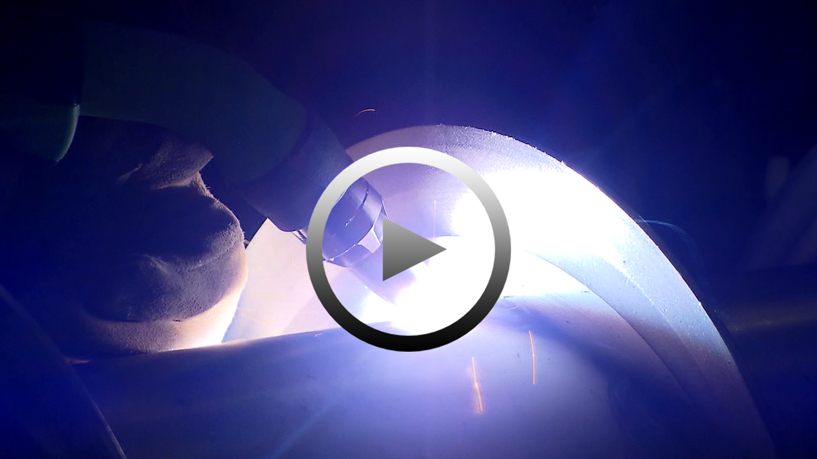

Translas’ Corporate Movie – Reflecting The Company’s Vision About The Future

Translas is a company with 55 years of experience in the welding industry. Throughout this time, we have succeeded to stay on top of the industry by thinking in the future and spotting what are the true needs of the welders. Some of our developments

Read More

Translas is a company with 55 years of experience in the welding industry. Throughout this time, we have succeeded to stay on top of the industry by thinking in the future and spotting what are the true needs of the welders. Some of our developments we have created through successful partnerships based on trust.

Translas is presenting you a company movie that reflects the long path taken and the vision of Translas about the future. Translas aims to improve the world by creating sustainable products from the beginning till the end – from the manufacturing process and distribution to healthy welding environment for welders all around the world. In order to develop more sustainable and welder-friendly products, we are constantly improving ourselves in terms of quality, efficiency, creativity as well as trust.

Translas’ products are made by welders, for welders.

Airforce Fresh Air Set: New Fresh Air Set (Papr)

Inhalation and exposure to welding fumes may cause irritation to eyes and skin, nausea, headache, dizziness and chronic injury to airways, lungs and nervous system. Such symptoms can sometimes reveal themselves after weeks, months or years. Therefore

Read More

Inhalation and exposure to welding fumes may cause irritation to eyes and skin, nausea, headache, dizziness and chronic injury to airways, lungs and nervous system. Such symptoms can sometimes reveal themselves after weeks, months or years. Therefore, wearing a welding helmet with a fresh air system during welding is a must for every welder!

Work safe and healthy with the AirFORCE Fresh Air set

As an addition of the FORCE program personal protection products, Translas now introduces the AirFORCE Fresh Air Set. With this Fresh Air set welders can protect themselves against harmful welding rays and welding fumes. The AirFORCE Fresh Air Set consists a FORCE-800 welding helmet and an AirFORCE Fresh Air unit. The FORCE-800 welding helmet is a high standard and comfortable welding helmet available with an auto-darkening welding filter 820S or 830S.

AirFORCE Fresh Air system

The AirFORCE Fresh Air unit is a light and compact filter system in a solid casing, connected to the FORCE-800 welding helmet. The fan in the fresh air system is driven by a carbon brush free motor. This motor is not only quiet but also has a three times longer lifetime than a conventional motor.

The Long-lasting Battery

A rechargeable battery provides the power to the fan motor. Depending on the contamination of the filter, the battery lasts 9 hours. An acoustic sound provides a warning signal when the voltage of the battery is too low. A separate charging station will be supplied with the AirFORCE Fresh Air unit.

The Filters

When the main filter is polluted, it must be replaced. The unit gives an alarm through a vibration signal and a bleeping sound, accompanied with flash of all three warning lights. The degree of saturation of the main filter will not affect the airflow. The main filter is protected on the outside by a spark trap and a pre-filter. Only the pre-filter can be cleaned with compressed air.

High Wearing Comfort

The lightweight fresh air unit is worn with a belt around the waist so that the unit and the air hose do not cause any obstruction during welding. The inside of the belt is designed with a soft shock absorbent material. The extra wide belt ensures that the carried weight of the unit is distributed over the full width and is not applying pressure to the lower back region during use.

Watch The Official Trailer Of The Extractor

Click on the video below to see the official trailer of the EXTRACTOR. Feel free to share this movie. F

Read More

Click on the video below to see the official trailer of the EXTRACTOR.

Feel free to share this movie. For more technical information on the EXTRACTOR, click here.

European Innovation Award For Extractor Welding Torch

The Extractor, an innovative welding torch that takes away 90 to 95% of harmful welding fumes directly at the source, has been awarded the EARTO Innovation Award 2015. This international award of the European Association of Research and Technology Or

Read More

The Extractor, an innovative welding torch that takes away 90 to 95% of harmful welding fumes directly at the source, has been awarded the EARTO Innovation Award 2015. This international award of the European Association of Research and Technology Organisations was presented to the developers of the Extractor by Carlos Moedas, European Commissioner for Research, Science and Innovation in Brussels on 14 October 2015. The Award was accepted by Bas Knoll of TNO in the absence of the two TNO researchers Ellemieke Henquet and André Moons, who were responsible for the research and development of the conical extraction system of the Extractor welding torch.

The Award

The Award was presented by the European Association of Research and Technology (EARTO), which was established in 1999 and represents the interests of more than 350 European research and technology organisations (RTOs) in European political circles and European R&D research programmes. The Awards have been presented since 2009 to RTOs that have contributed significantly to innovation.

Of the 26 entries, 6 innovations made the final, divided over two categories: ‘Impact Delivered’ and ‘Impact Expected’. Innovations in the first category have already demonstrated their social and economic worth and been placed on the market. The Extractor was placed in this category in the final, up against the formidable opposition of the German Fraunhofer-Institut and Sweden’s SP Technical Research Institute, but in the end the Extractor prevailed.

The Extractor welding torch: breakthrough for a healthier working environment

The Extractor takes away the welding fumes directly at the source and reduces them by 90 to 95% without any concessions to the weld quality. This means that welders and others working in the same area are no longer exposed to harmful welding fumes. Once its use has become widespread the health of some 730,000 welders in Europe will be improved. Reducing the health hazard caused by exposure to welding fumes has been an important topic for many years. The fact that a solution is now available therefore represents a true breakthrough. The Extractor also saves substantial costs through:

Developed in close partnership

Translas developed the EXTRACTOR welding torch in partnership with the independent Dutch research institute TNO and the innovation platform iTanks. Translas is responsible for the entire production and sales operation.

New: 7St Tig Welding Torches Series

The new TIG welding torch is the first TIG welding torch which, thanks to a modular design, can connect to any kind of cable end, adapter, and switch module. The new TIG welding torches are not only easy to customise, but enable any type of welding i

Read More

The new TIG welding torch is the first TIG welding torch which, thanks to a modular design, can connect to any kind of cable end, adapter, and switch module. The new TIG welding torches are not only easy to customise, but enable any type of welding instrument to be put together. As a result, end users no longer need to buy a complete new welding torch for each instrument they require and dealers can reduce their inventory level.

Screwless interchangeable modules

The new TIG welding torch has the 7 series family look and is the third generation in the line of torches that Translas introduced in 2005. Existing TIG torch lines already had a fully closed switch system and could be delivered with a single as well as a multiple pressure switch module. This is no longer unique, but the new generation can now be put together with 7 different switch modules, which can exchange easily without screwing parts together. And that’s unique!

Further ergonomic improvements

Translas has improved the design of the new TIG torch handle for a better hand grip. We also researched the optimal distance between the switch and the welding tip. We have now implemented this across the entire line, enabling the manual welder to exercise better control of torch movements. Also new is the lower cover with gripstuds which is optimal grip guaranteed.

BY WELDERS, FOR WELDERS.

Force 800 Welding Helmet

Welding helmets provide good protection against harmful UV rays, but they should also be easy to use and comfortable to wear. The FORCE-800 is a light, top-range, high-quality welding helmet belonging to the top segment of the market. As a standar

Read More

Welding helmets provide good protection against harmful UV rays, but they should also be easy to use and comfortable to wear. The FORCE-800 is a light, top-range, high-quality welding helmet belonging to the top segment of the market.

As a standard this helmet is supplied in our own FORCE design. It is also possible, for orders of 300 units or more, to supply this helmet with your own label or brand. For larger quantities, other helmet shells and/or cassettes are also available on request.

With a choice of two automatic cassettes, type 820 or 830, the FORCE-800 welding helmet provides the eyes with maximum protection against harmful UV rays. The FORCE-820 cassette has a field of vision of

95×85 mm (classification 1/2/1/1). The FORCE-830 cassette comes with a digital display and a field of vision of 65×62 mm (classification 1/1/1/1). Both automatic cassettes are of course fully CE certified in accordance with the prevailing directives.

This new FORCE-800 is a top-range welding helmet against a reasonable price. For more information, prices and conditions, please get in touch with our sales department: info@translas.com / (+31)30 – 604 73 73.

Translas Nominated For Accenture Innovation Award 2014. Cast Your Vote!

Translas is proud of its nomination for the Accenture Innovation Award 2014. Our 7XM Extractor is in the running for this prestigious prize in innovation. The great thing about this award is that you can help us win by casting your vote at https://in

Read More

Translas is proud of its nomination for the Accenture Innovation Award 2014. Our 7XM Extractor is in the running for this prestigious prize in innovation. The great thing about this award is that you can help us win by casting your vote at https://innovation-awards.nl/concept/ivent/ [closed].

The 7XM Extractor welding torch was developed by Translas, TNO Research Institute and Stichting iTanks Rotterdam (NL). This particular welding torch is innovative in a number of ways. Tests carried out by TNO have shown that the Extractor is the first smoke-extraction torch to go under the Maximum Allowable Concentration (MAC) value of 1 mg/m³. This means the welding torch contributes significantly to the healthy and safe working conditions of welders. In the Netherlands alone this amounts to 75,000 people.

The 7XM Extractor also excels in other areas in terms of innovation:

Vote now!

In short: the 7XM Extractor deserves the Accenture Innovation Award 2014. You can vote now on https://innovation-awards.nl/concept/ivent/ [closed]. Tip: you can cast your vote more than once via Facebook, LinkedIn, Twitter and e-mail.

About the Innovation Awards

Accenture initially established the Innovation Awards with the objective of duly rewarding those companies that provide exceptional, innovative performance. In addition, the event offers comprehensive insight into the state of innovation in the Netherlands. For the jury awards – the Blue Tulip and the Green Tulip – the nominees are assessed on innovation, success and potential by a panel of expert judges.

The Green Tulip is an overarching industry prize for the most sustainable concept originating from the Netherlands. Accenture, together with the Club of Rome, created the Green Tulip to emphasise the importance of sustainable innovation.

All in keeping with our motto: By Welders, For Welders.

Welding Shops Are Now Able To Attract More Customers With New Appealing Packaging

From the end of July we will be providing our retailers with new packaging. The new sealed bags look very attractive compared to the previous ones. They also have numerous benefits, such as high-quality strong plastic, ribbed header, tear-open cut to

Read More

From the end of July we will be providing our retailers with new packaging. The new sealed bags look very attractive compared to the previous ones. They also have numerous benefits, such as high-quality strong plastic, ribbed header, tear-open cut to open the bag easily and big label space.

The new bags not only have a more professional look but are also designed for private labelling. The manufacturer logo can easily be removed and there is enough space to place your private label (70x40mm). This makes it very easy to customize.

The ribbed header and the high-quality plastic used allow you to hang the bags without them loosing their form. This feature drastically improves the visual presentation of the store. The hanger and display look neat and representative to the customer.

The reason why we decided to change our packaging is to help our retailers with attracting more end consumers of welding products. The full range of products we offer will be received in the new packaging from the the end of July 2014.

Get more information or place your order: info@translas.com

The Third In A Row Bicycle Ride Collects 9000 Euro To Fight Cancer

Saturday 21st June took place the ven2cops bicycle ride. The aim of the bike ride was to collect money for the fight against cancer. At the end of the event 9000 euro were collected by the participants and sponsors. Translas BV also participated with

Read More

Saturday 21st June took place the ven2cops bicycle ride. The aim of the bike ride was to collect money for the fight against cancer. At the end of the event 9000 euro were collected by the participants and sponsors. Translas BV also participated with a contribution.

The bicycle ride was organized for 3rd time and every time it has a bigger success. This time the 100 enthusiastic participants had to cycle a distance of 100km.

Every year Translas BV sponsors charity events of different kinds. We believe that companies and organisations should contribute more often to support good causes.

The Rocker Switch Is More Comfortable Than Ever

As a producer who always strives to listen to the needs of the welder, we continuously improve our products. Feedback from users of our torches always makes us happy and we do everything possible to eliminate their complains or small inconveniences.

Read More

As a producer who always strives to listen to the needs of the welder, we continuously improve our products. Feedback from users of our torches always makes us happy and we do everything possible to eliminate their complains or small inconveniences. Recently, our team in Nieuwegein, the Netherlands has finished the improvements on the rocker switch, namely:

High-sensitivity Switch

The rocker has been improved in two ways. The first one is the sensitivity of the switch. Now the welder can easily press the switch to the front and back. In this way they can control the stream to perfection.

Even More Stable